Unique protective layer of extra dense ceramic phases

Iron-based cylinder wear protection

Highest density of ceramic phases

Reiloy iron-based alloys deliver better wear protection with the same hardness at the best cost-benefit ratio on the market.

Only with Reiloy iron-based alloys do ceramic phases form a protective wall at the surface

Our entire process is designed to form this specifically designed ceramic layer that other alloys do not possess. We have also developed the special Reiloy centrifugal casting process and machines that are optimally adapted to it. The result: a micro-hardness of the ceramic phases of 1600 HV0.1 with an intermediate matrix that provides exactly the right degree of elasticity to prevent the surface from splintering. This is the best wear protection in this class of material - at a price worthy of comparison.

Reiloy iron-based alloys in detail

Compared with a conventional iron-based alloy (right), the uniquely high density of the ceramic phases in Reiloy alloys forms a deep protective layer just below the honed surface.

Excellent corrosion resistance in 24h salt spray test

Corrosion resistance made visible: Reiloy R121 visibly performs more convincingly than other wear protection alloys in the 24h salt spray test.

The alloy for verifiably longer barrel service life

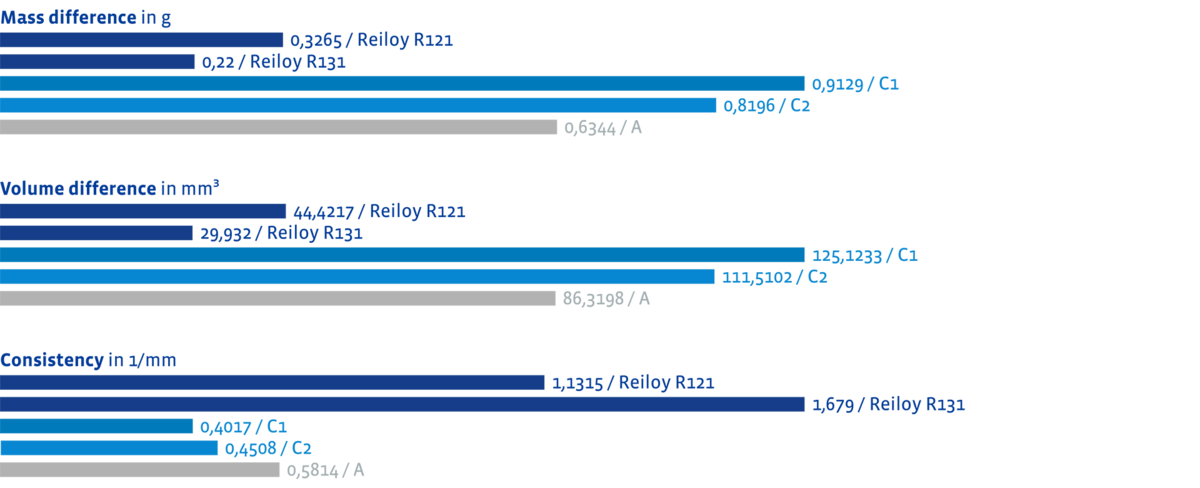

In a market comparison, Reiloy alloys clearly outperform the competition in all key wear protection parameters.