Unique protective layer of extra dense ceramic phases

Iron-based cylinder wear protection

Highest density of ceramic phases

Reiloy iron-based alloys deliver better wear protection with the same hardness at the best cost-benefit ratio on the market.

Only with Reiloy iron-based alloys do ceramic phases form a protective wall at the surface

Our entire process is designed to form this specifically designed ceramic layer that other alloys do not possess. We have also developed the special Reiloy centrifugal casting process and machines that are optimally adapted to it. The result: a micro-hardness of the ceramic phases of 1600 HV0.1 with an intermediate matrix that provides exactly the right degree of elasticity to prevent the surface from splintering. This is the best wear protection in this class of material - at a price worthy of comparison.

Reiloy iron-based alloys in detail

Compared with a conventional iron-based alloy, the uniquely high density of the ceramic phases in Reiloy alloys forms a deep protective layer just below the honed surface.

Reiloy iron-based alloys in competitive comparison

The animation shows: Due to the microstructure of their armor layer, Reiloy iron-based alloys ensure

better long-term protection against abrasive particles with the same hardness.

The Reiloy Alloy Advisor - Find the right alloy for your individual application here

Matching Screw

For each barrel, Reifenhäuser Reiloy also offers the precisely fitting screw that represents the most economical solution for your application - also thanks to our individual design consulting.

Here's how:

1) Schedule an application consultation.

2) Select the screw that fits your requirements.

3) Master production challenges with ease and profit for a long time.

Please review the data sheet below or contact a Reiloy expert for assistance. We will be happy to advise you!

Excellent corrosion resistance in 24h salt spray test

Corrosion resistance made visible: Reiloy R121 visibly performs more convincingly than other wear protection alloys in the 24h salt spray test.

The alloy for verifiably longer barrel service life

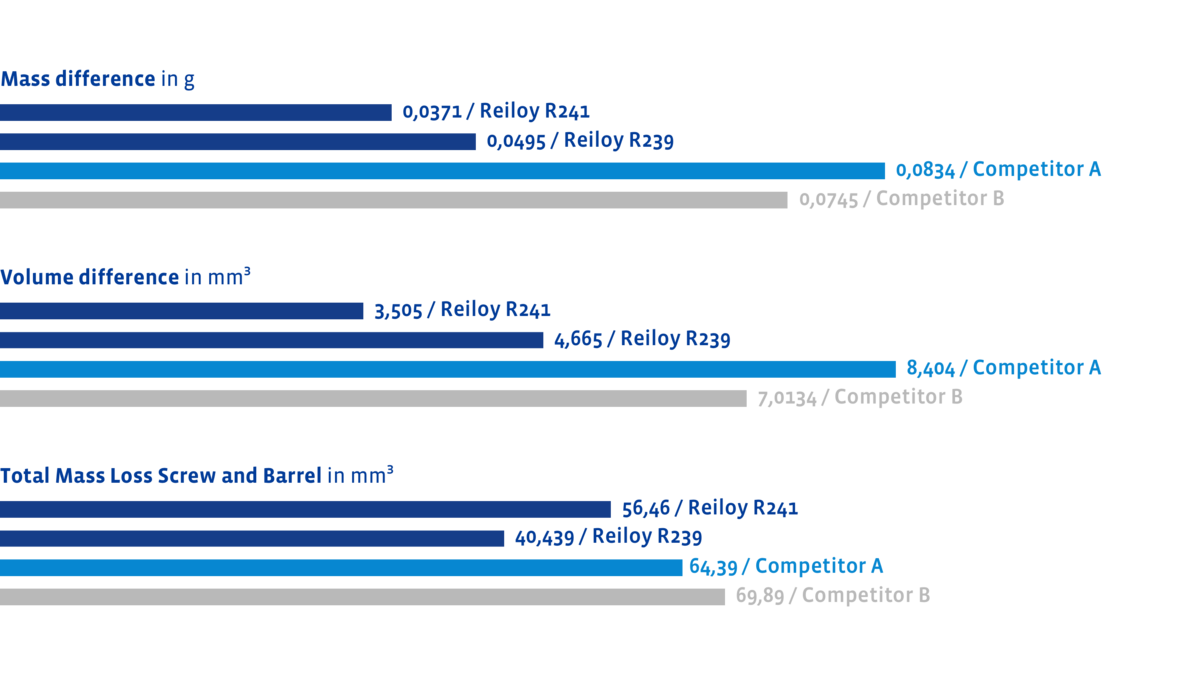

In a market comparison, Reiloy alloys clearly outperform the competition in all key wear protection parameters.

The abrasive wear was evaluated with the so-called pin-on-paper test in the Reiloy laboratory. Measurements were taken 4 times for 90 seconds on 220-grit abrasive paper under a contact force of 70N.

Wear protection knowledge in detail

That is why we have compiled the most important terms with brief explanations for you in our wear protection glossary. So that you know even more precisely which factors have a decisive influence on the service life of your cylinders.

Abrasion occurs through the action of a hard surface scoring another softer surface. This results in plastic deformation and cutting of furrows in the softer surface. Material can be removed from the groove ("microplowing") or chipped out ("microchipping"). Abrasive wear in plasticizing units is mainly caused by the type and content of (inorganic) fillers and additives.

The effects of adhesion can occur when the base and counter surfaces move against each other under increased pressure. Both surfaces have roughness peaks that may result in cold welding. This may lead to what is known as score marks and grooves in the surfaces. In plasticizing units, the effects of adhesion mainly occur in the area of the feed zone where direct metal-to-metal contact can occur between the screw and the barrel wall.

Additives comprise functional substances such as heat and light stabilizers, plasticizers, processing additives, antistatic agents, adhesion promoters, flame retardants and dyes. These substances can be abrasive, corrosive or a combination of the two.

Borides are chemical compounds consisting of the element boron and metals. These types of metal-boron compounds often have ceramic properties. Among other things, they result in a high degree of hardness, which is why borides often play an important role in wear protection.

Carbides are chemical compounds consisting of the element carbon metals. These types of metal-carbon compounds often have ceramic properties. Among other things, they result in a high degree of hardness, which is why carbides often play an important role in wear protection.

The size of carbides has a significant influence on the wear behavior or wear resistance of the barrel. Larger carbides act more selectively against coarse abrasive wear in the barrel.

Carbides themselves are not attacked by abrasive substances, but are simply in the way - the large ones more so than the small ones.

This is similar to stones in a field that is to be plowed: the plow simply pushes the smaller stones aside, but the larger stones present an obvious obstacle.

Manufacturing process for bimetallic barrels with high-purity hardfacing layers.

A powder compound is filled into the predrilled barrel and the barrel ends are welded shut. During the centrifugal process on the machine, the barrel blank is rotated and simultaneously heated until the powder filling is fully melted or becomes liquid. Due to centrifugal forces acting on the melt as a result of rotation, the melt deposits on the inner wall of the barrel. The rotation of the barrel is maintained during the cooling process to allow the melt to solidify on the inner wall of the barrel. The solidified layer on the inner wall of the barrel is the hardfacing layer which is vital to the wear resistance of the barrel.

Ceramic phases (e.g. borides, carbides) form in highly alloyed iron-based alloys during the solidification process from the liquid melt. In order for the ceramic phases to precipitate in the process, the chemical composition, process temperatures and times must be precisely coordinated and maintained.

The ceramic phases provide high hardness, wear resistance, and corrosion resistance. The alloying concept of Reiloy R121 was designed specifically with the formation of these phases in mind.

Corrosion is a change in the material surface caused by undesired chemical or electrochemical attack. It is based on the oxidation of the (ferrous) material.

Corrosion wear is one of the tribochemical wear mechanisms in which chemical and mechanical effects are superimposed. When a metallic material reacts with its environment, a reaction product (e.g. a porous oxide layer) forms on its surface. This porous oxide layer is easily removable by prevalent abrasion processes, thereby rendering the surface bright again. The bright surface then reacts again with its environment; a porous oxide layer is again formed by corrosion and this is again removed by abrasive attack. This self-perpetuating mechanism can lead to excessive material loss over time.

Dye pigments usually consist of metal oxide compounds. Since dye pigments are insoluble in the plastic, they move uncontrollably between the screw and barrel as "wear particles" and, due to their high degree of hardness, they may contribute to abrasive wear in the plasticizing unit.

Hardfacing alloy based on the element iron with additional alloy elements.

The hard phases are formed in the production process as the melt solidifies. Examples of Fe-based Reiloy alloys are R121 and R131.

Flame retardant additive are admitted to inhibit ignition. When a substance-dependent temperature threshold is exceeded, flame retardants are usually released in gaseous form and then develop their particular effect. These agents often contain bromine, phosphorus or chlorine compounds that can have a corrosive effect on the screw and barrel during processing/plasticizing.

Dimension for the (weight) proportion of fillers and additives, usually given as a percentage.

A distinction is made between active and inactive fillers. Active fillers enhance the mechanical and physical properties of the product. Inactive fillers are primarily intended to reduce the cost of the plastic product.

Glass fibers and beads are important reinforcing agents added to the plastic molding compound.

In the processing stage, glass fibers can break due to high shear forces in the plasticizing unit, resulting in sharp fracture edges at the fiber ends, and this may cause abrasive damage to the metallic surfaces.

The hardness of a material corresponds to its resistance to penetration by another surface or test specimen.

In hard alloys, the hard phases form "in-situ" from the liquid melt during the solidification process. The alloy composition and the cooling process must therefore be precisely matched for this to occur. The size and density of the hard phases formed in this way provide the wear resistance.

Examples are the hardfacing alloys R121 and R131.

In contrast to hard alloys, the hard material particles in hard composites are added in the solid state and are not produced "in-situ" from a melt. As a result, a mixture of two starting components is used: a powdered metallic matrix alloy, and hard material particles (for example tungsten carbide). In the subsequent production process, the matrix powder melts at elevated temperatures, but the hard materials do not. After cooling, the hard materials are then firmly embedded metallurgically in the solidified metal matrix. In later applications, the hard materials ensure high wear resistance, while the more ductile metal matrix provides a supportive function for them.

Examples are the hardfacing alloys R241 and R239.

Honing is a machining application in production (cutting with a geometrically undefined cutting edge).

In the production of bimetallic barrels, it is the final manufacturing step to remove the slag and oversize from the barrel after the centrifugal casting process. Honing is the process of obtaining the required internal dimensions and surface roughness of the barrel. After honing, the typical cross grinding pattern can be seen on the inner wall of the barrel.

Honing tools and stones must be precisely matched to the properties of the hardfacing alloy to be honed in order to achieve effective and efficient removal of the material. The composition of the honing stone combined with the honing parameters also determines the surface roughness of the hardfacing layer after honing.

A master batch is generally defined as granules consisting of a carrier material with a highly concentrated content of dyes and/or additives.

A distinction is made between three types of master batches:

- Color master batches for dying plastic products.

- Additive master batches for specific properties of the end products (e.g. UV stabilization, flame retardancy, antistatic properties)

- Combination master batches containing both dyes and additives.

Admixing additives using filled master batches may have the effect that the carrier material already melts at temperatures at which base material granules are still present as solids. In this way, the batch grains released interact with the unmelted granules of the base material and have an extreme sandpaper-like effect on the metallic surfaces, thus promoting wear.

Hardfacing alloy based on the element nickel with additional alloy elements.

The hard phases (tungsten carbides) provide the wear resistance and are added separately to the powder compound. Particularly suitable for applications with high corrosivity and/or coarse abrasive wear. An example of a Ni-based Reiloy alloy is R241.

Polymers are macromolecules contained in a plastic material. Polymers are molecular compounds that consist of many repetitive monomers and have a correspondingly wide range of properties.

Surface mechanical attrition is caused by the cyclical mechanical loading of a material surface. After a critical number of deformation cycles has occurred, microcracks form and grow close to the surface, resulting in chipping and further damage to the surface (material fatigue).

Tribology refers in general to the study of friction, lubrication, and wear. It describes the processes on the surface of a solid body in moving contact with another surface.

In three-body abrasion, solids affect the surfaces of two contacting bodies (e.g., in a plasticizing unit, strong forces may act abrasively in the gap between the screw channel and the barrel).

Tungsten carbide is a hard material widely used in wear protection applications and cutting tools. The characterizing feature of tungsten carbide is its high degree of hardness that almost approaches the hardness of diamond. In plasticizing units, for example, a wide variety of tungsten carbide grades are used as hard materials in Ni-based barrel hardfacing layers or in Ni-based screw channel hardfacing layers. The carbide size has a decisive influence on the wear behavior of the barrel/component.

also: tribological system Usually consists of four elements (base body, contacting body, intermediate medium, ambient medium). Wear mechanisms occur in combination and may overlap.

In the case of a plasticizing unit, the interaction of screw and barrel can be defined as a tribosystem, depending on the properties of the extrudate (e.g. fillers, additives).

Two-body wear occurs by direct contact between two surfaces of a tribosystem.

Wear is the progressive loss of material from the surface of a solid body caused by mechanical effects, i.e. contact and relative movement of a solid, liquid or gaseous contacting body.

The pin on drum wear test involves testing two test specimens against each other. A pin-shaped specimen made of a barrel hardfacing alloy and a rotating drum made of a screw alloy are pressed against each other at a constant standard force. The drum is rotated at a constant speed, the pin is stationary.

Depending on the material pairing, either the pin or the drum wears more; or wear on the pin and drum is similar. Material loss is determined by weighing the two test specimens before and after the test.

The aim is to obtain a realistic simulation of the adhesive wear behavior of different barrel hardfacing alloys or different barrel/screw hardfacing material pairings with a high degree of comparability.

In the pin on disk wear test, a plane-ground pin specimen of the barrel alloy is pressed against a rotating grinding disc. The grinding disc is fitted with a silicon carbide disk, which is a strong abrasive. Material loss is determined by weighing the two pin specimens before and after the test periods.

The test can be used to estimate the attack resistance of the barrel hardfacing alloy to additive particles or fillers.

Four main common wear mechanisms are defined in the literature:

- abrasive wear

- adhesive wear

- surface mechanical attrition

- tribochemical reaction

Mechanisms "1", "2", and "3" are based on mechanical action, whereas mechanism "4" results from chemical and mechanical action ("corrosive wear"). The main wear mechanisms occurring in a plasticizing unit vary from case to case. However, very often, several wear mechanisms overlap.

Wear volume can be determined from the weight loss (weighed before and after the test/use) via the specific density of the hardfacing layer.

In the context of plasticizing units, wear volume is usually a more meaningful parameter than pure mass loss from wear since wear volume describes the gap size between the screw channel and the barrel wall.