10 times larger carbides than in comparable alloys

Nickel-based alloys

Greater protection thanks to larger carbides

Reiloy nickel-based alloys offer significantly better wear protection with the same hardness and the best cost-benefit ratio in the industry.

Nickel-based alloys from Reiloy withstand the abrasive forces in the barrel through extra large carbides.

The carbides themselves are not attacked by abrasive substances, but are simply in the way - the large ones more so than the small ones. Like stones in a field being plowed where the plow represents the abrasive forces: The plow simply pushes the smaller stones aside. The larger stones present an obvious obstacle and prevent the plow from tilling the soil. Similarly, larger carbides obstruct abrasive forces and offer significantly more resistance than smaller ones. The result: significantly greater wear protection effectiveness and longer service life for your barrels.

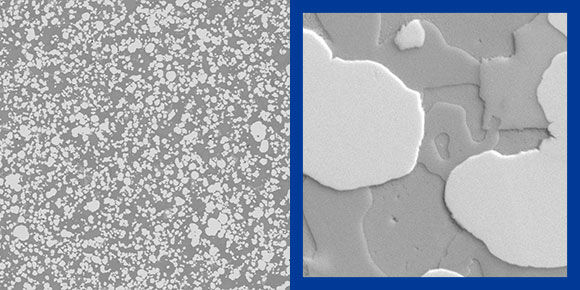

How Reiloy’s extra large carbides work

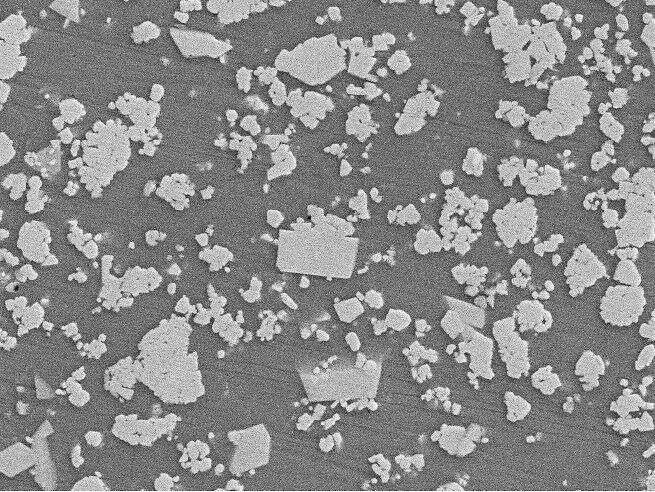

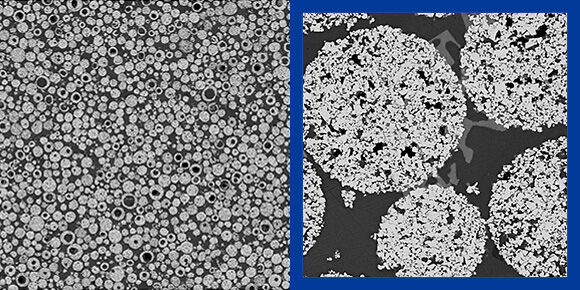

Conventional nickel-based alloys

Conventional nickel-based alloys provide plenty of space between the smaller carbides for abrasive attack.

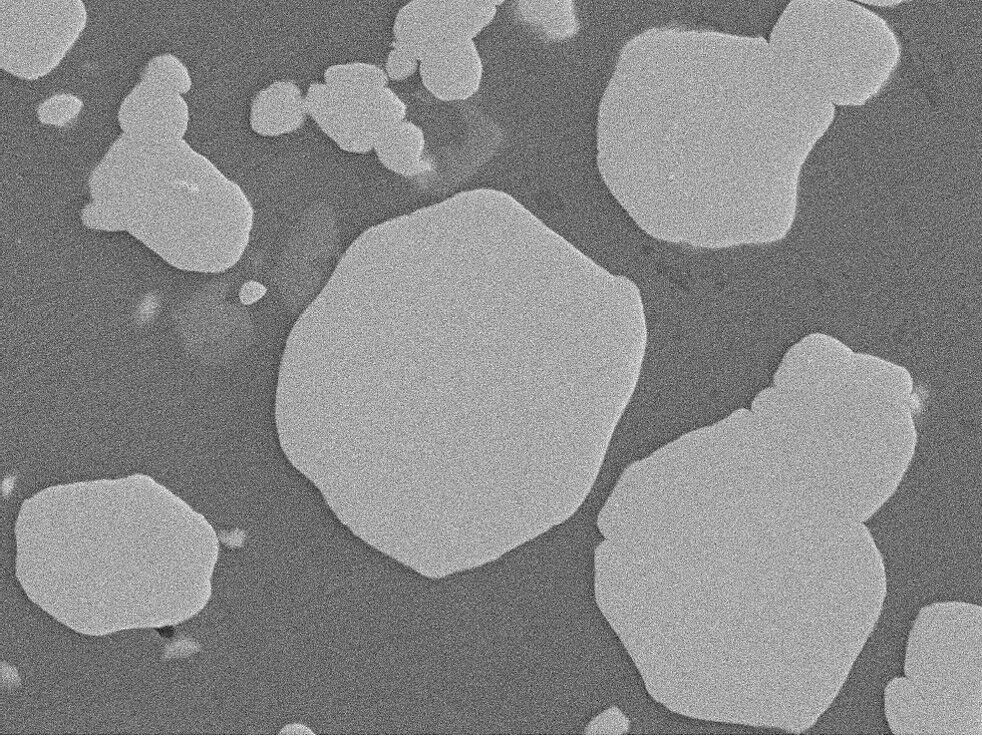

In Reiloy nickel-based alloys

In Reiloy nickel-based alloys, the carbides are ten times larger and occupy much more space, significantly reducing the attack surface for abrasive materials.

Smart alternative: nickel-based alloy R239

There are applications where wear attack is so aggressive that it is impossible to use an iron-based alloy, but is still moderate enough to not require Premium wear protection. For such applications, we developed the Reiloy nickel-based alloy 230 containing tungsten carbides. The carbide size complies with our brand standard and reliably fulfills all warranty conditions in Reiloy quality - and at a price that gives your margin headroom. It also lengthens the service life of the screw. Request a consultation.

Reiloy iron-based alloys in detail

Premium

R241

Maximum wear and corrosion protection

| Wear resistance | +++++ | |

| Corrosion Resistance | +++++ | |

| Layer thickness | min. 1,0 mm | |

| Roughness Ra | min. 0,3 – max. 0,8 | |

| Inner diameter | 15 – 300 mm | |

| Outside diameter | max. 600 mm | |

| Length | max. 9.000 mm | |

| Hardness at room temperature | min. 59 HRC | |

| Main alloy component | W, Cr, B | |

| Structural description | Dispersive hardening of a highly corrosive resistant Ni matrix alloy with thermally stable tungsten carbides |

Advanced

R239

Maximum resistance to corrosive stress

| Wear resistance | ++++ | |

| Corrosion Resistance | +++++ | |

| Layer thickness | min. 1,0 mm | |

| Roughness Ra | min. 0,2 – max. 0,8 | |

| Inner diameter | 18 – 165 mm | |

| Outside diameter | max. 290 mm | |

| Length | max. 3.000 mm | |

| Hardness at room temperature | min. 58 HRC | |

| Main alloy component | W, Cr, B | |

| Gefügebeschreibung | Dispersive hardening of a corrosive highly resistant Ni matrix alloy with common tungsten carbides. |

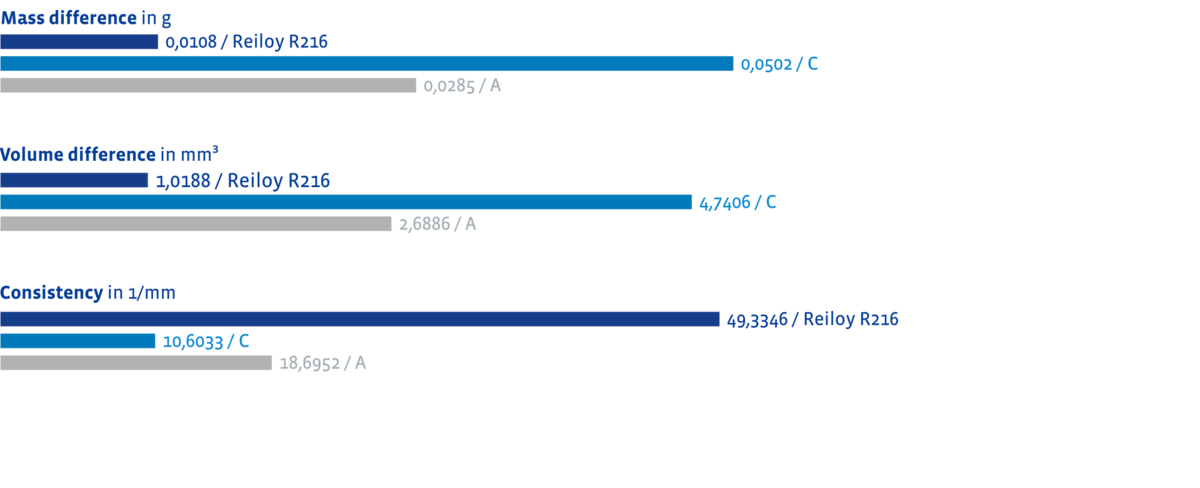

The alloy for demonstrably longer cylinder life

In a market comparison, Reiloy alloys clearly outperform the competition in all key wear protection parameters.