1.

联系我们

莱洛伊机筒

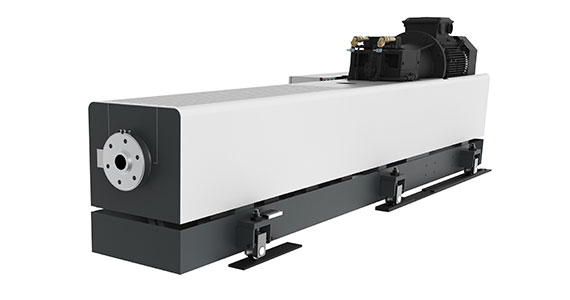

使用寿命长,质量好,具有一流的磨损保护

质量稳定的机筒,为您的塑化装置提供更长的保护,防止粘连、磨损和腐蚀,即使是加工造成强烈磨损的原材料。

值得期待的事情

莱洛依机筒的亮点

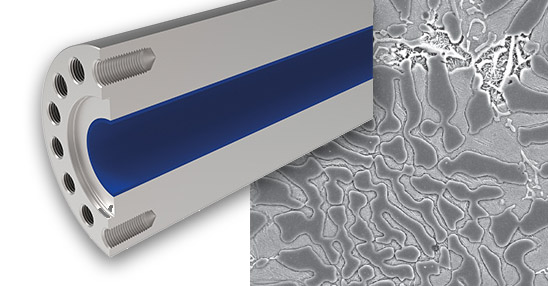

与我们的合作伙伴一起,我们根据最新的技术成果开发出耐磨保护装置

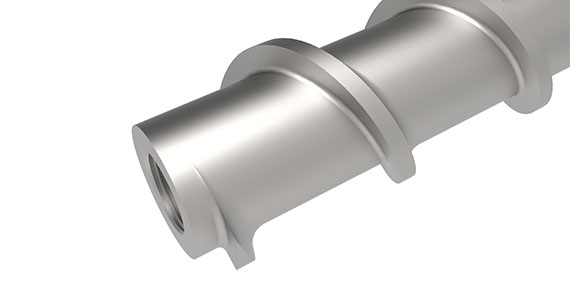

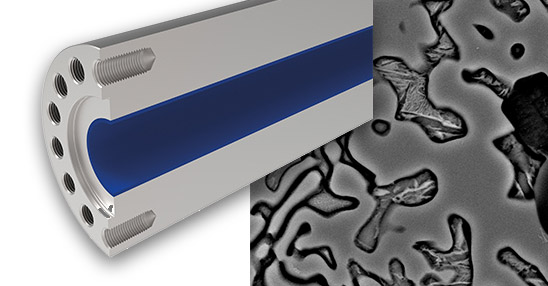

莱洛伊双金属机筒结构紧凑

关键数据一目了然

.jpg)

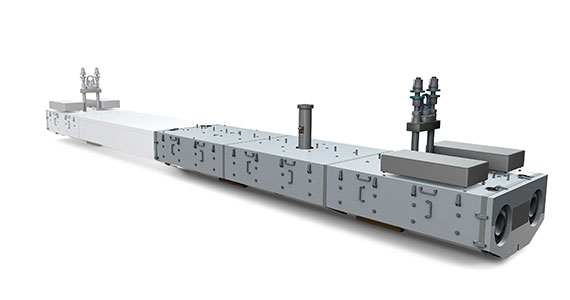

| Design | Blank barrel Semifinished barrel Finished barrel |

| Inside diameter | 14-400 mm |

| Max. outside diameter | 600 mm |

| Max. length | 9000 mm |

从标准到高端

您的选项

您对塑化装置的使用寿命和成本效益的要求决定了哪种是适合您的。我们在咨询中一步一步地指导您找到最佳解决方案。

Smart

Advanced

Premium

你想生产什么?

选择正确的

For plastics with a filler content up to 30%

Hard metal alloy on iron base. Excellent wear resistance and good corrosive resistance.

ABS, ASA, CA, COC, EVA, HDPE, HIPS, LDPE, PA, PBT, PC, PEEK, PEI, PESU, PET, PF, PMMA, POM, PP, PPA, PPS, PPSU, PS, PS transparent, PSU, PVC-C, PVC-P, PVC-U, PVDF, SAN, SB, TPE, TPU

Alloys

| Injection Molding | Reiloy standard R121 |

| Extrusion | C60 (1.0601) R1 |

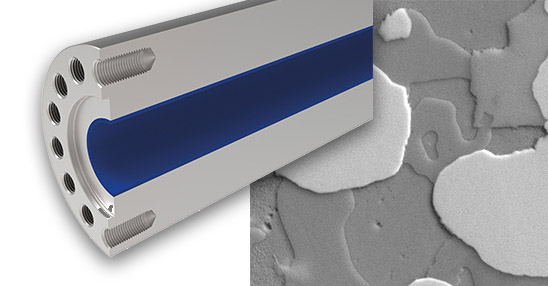

For plastics with a filler content up to 40%

Hard metal alloy on iron base with added vanadium. Very high wear and corrosive resistance with enhanced ductility.

ABS, ASA, EVA, HDPE, HIPS, LDPE, PA, PBT, PEEK, PEI, PESU, PET, POM, PP, PPA, PPS, PPSU, PSU, PVC-C, PVC-P, PVC-U, TPE, TPU

Alloys

| Injection Molding | Reiloy Standard R131 |

| Extrusion | Reiloy Standard R131 |

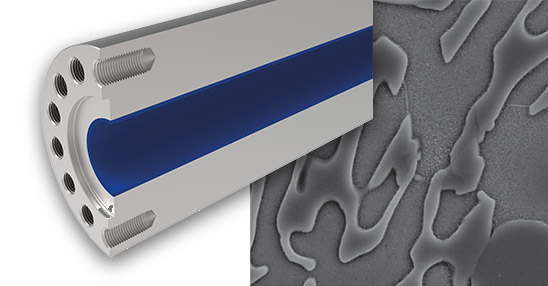

For plastics with a filler content greater than 40%

Two-phase hard metal alloy on nickel base with tungsten carbides. Maximum wear and corrosive resistance.

ABS, ASA, EVA, HDPE, HIPS, LDPE, PA, PBT, PEEK, PEI, PESU, PET, POM, PP, PPA, PPS, PPSU, PSU, PVC-C, PVC-P, PVC-U, TPE, TPU

Alloys

| Injection Molding | Reiloy Standard R241 |

| Extrusion | Reiloy Standard R241 |

For special applications

We offer special alloys for the production of complex products, such as PRFE, PFA, FEP.

在这里找到适合你的原材料的合金,并比较使用寿命和经济性。

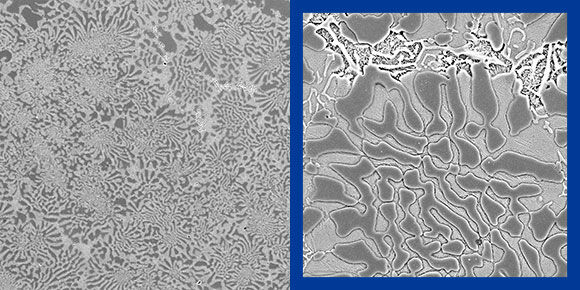

延长使用寿命

用优秀的合金节约成本

市场上各种各样的合金可能令人困惑。我们的专家指导您进行选择,并与您合作,找出最适合您的双金属机筒生产的装甲合金。

Smart

R121

卓越的耐磨性和良好的耐腐蚀性

| Wear resistance | +++ | |

| Corrosion resistance | +++ | |

| Layer thickness | 1.5 mm | |

| Roughness Ra | min. 0.2 – max. 0.8 | |

| Inner diameter | 14 – 400 mm | |

| Outside diameter | max. 600 mm | |

| Length | max. 9,000 mm | |

| Hardness at room temperature | min. 65 HRC | |

| Main alloy component | Cr, Ni, Mo, B | |

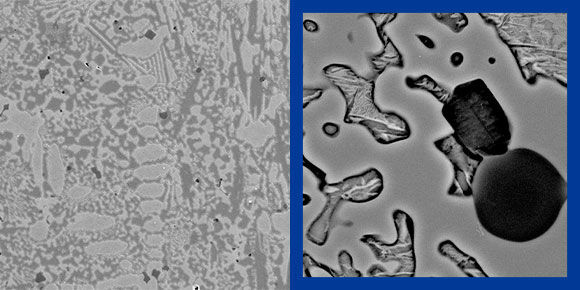

| Structural description | Martensitic iron-based alloy with primarily solidified chrome carbides and Carbo-Boride Phases |

Advanced

R131

非常高的磨损和腐蚀保护,具有更好的延展性

| Wear resistance | ++++ | |

| Corrosion resistance | ++++ | |

| Layer thickness | 1.5 mm | |

| Roughness Ra | min. 0.2 – max. 0.8 | |

| Inner diameter | 14 – 90 mm | |

| Outside diameter | max. 230 mm | |

| Length | max. 3,000 mm | |

| Hardness at room temperature | min. 60 – 64 HRC | |

| Main alloy component | Fe, Cr, V, B, Ni | |

| Structural description | Martensitic iron-based alloy reinforced with vanadium carbides and Carbo-boride phases |

Premium

R241

最大的磨损和腐蚀保护

| Wear resistance | +++++ | |

| Corrosion Resistance | +++++ | |

| Layer thickness | min. 1.0 mm | |

| Roughness Ra | min. 0.3 – max. 0.8 | |

| Inner diameter | 15 – 300 mm | |

| Outside diameter | max. 600 mm | |

| Length | max. 9,000 mm | |

| Hardness at room temperature | min. 59 HRC | |

| Main alloy component | W, Cr, B | |

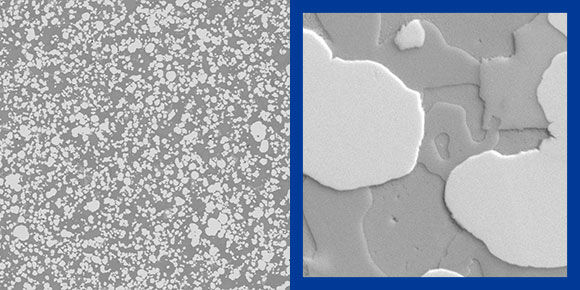

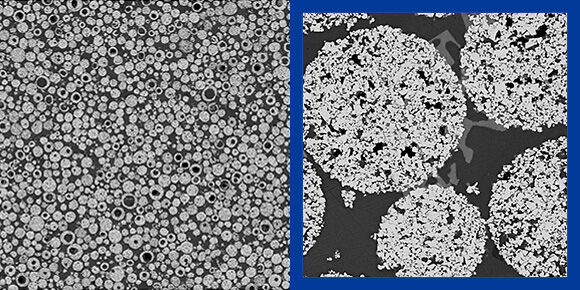

| Structural description | Dispersive hardening of a highly corrosive resistant Ni-matrix alloy with thermally stable tungsten carbides |

可选

R115

对腐蚀应力的最大抵抗力

| Wear resistance | + | |

| Corrosion Resistance | +++++ | |

| Layer thickness | min. 1.5 mm | |

| Roughness Ra | min. 0.2 – max. 0.8 | |

| Inner diameter | 15 – 105 mm | |

| Outside diameter | max. 350 mm | |

| Length | max. 3,000 mm | |

| Hardness at room temperature | min. 55 HRC, Di > 60 mm min. 47 HRC | |

| Main alloy component | Co, Cr, B | |

| Structural description | Nickel-cobalt base alloy with fine precipitation of primary solidified nickel borides and eutectically solidified chromium carbides |

Advanced

R239

高耐磨保护,具有最大的耐腐蚀性

| Wear resistance | ++++ | |

| Corrosion Resistance | +++++ | |

| Layer thickness | min. 1.0 mm | |

| Roughness Ra | min. 0.2 – max. 0.8 | |

| Inner diameter | 18 – 165 mm | |

| Outside diameter | max. 290 mm | |

| Length | max. 3,000 mm | |

| Hardness at room temperature | min. 58 HRC | |

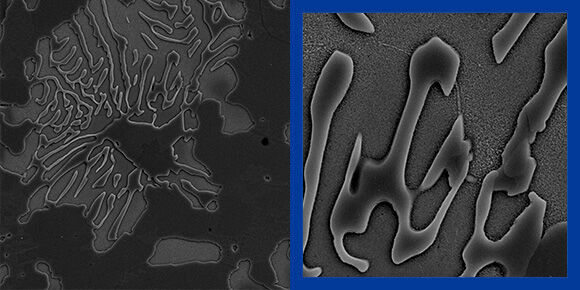

| Main alloy component | W, Cr, B | |

| Structural description | Dispersive hardening of a highly corrosive resistant Ni-matrix alloy with common tungsten carbides |

我们的承诺