1.

安排一次咨询

莱芬豪舍挤出机

拓展您的业务

定制的挤出机,支持您的生产目标,在生产中实现更大的利润。

值得期待的事情

莱芬豪舍挤出机的亮点

莱芬豪舍挤出机

我们的承诺

您想生产什么?

选择您的挤出机

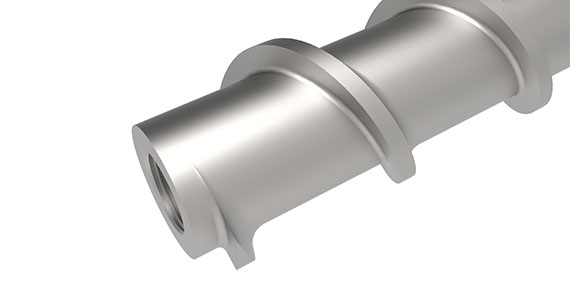

Reifenhäuser single-screw extruders match most product requirements, they are tailor-made and economically efficient. Owing to its wide range of applications and raw materials, this technology can be used with enormous flexibility. To ensure that the extruders match your product requirements perfectly, we design them to meet your requirements. Our extruder construction kit lowers the costs of customization.

- Polyolefins (PE & PP)

- Polyester (PET)

- polyamides (PA)

- Polystyrene (PS)

- Ethylene vinyl alcohol copolymer (EVOH)

- Adhesion promoter (HV)

- Thermoplastic elastomers (TPE)

- Polyvinyl chloride (PVC)

- Thermoplastic terpolymers (ABS)

- Polymethyl methacrylate (PMMA)

- Polycarbonate (PC)+ Circular Economy

- and others

Extruder (Ø) [mm] | 25 – 250 |

Process length [L/D] | 25 – 36 |

Screw type | 3-zone, vacuum or barrier |

Extruder design | Z-design, U-design |

Drive power [kW] | 5 – 600 |

Plasticising capacity [kg/h] | max. 1,500 |

Stop wasting valuable raw materials. The refeeding extruder returns film and nonwoven edge trim directly back to the production process. As opposed to solutions that use mills or regranulation, a refeeding extruder assures high film or nonwoven quality since it eliminates mill dust and thermal stress.

- Polypropylen (PP)

- Polystyrene (PS)

- LDPE

Extruder | Feeding section Ø | Outlet section Ø | Drive | Screw speed | Output PP |

[Type] | [mm] | [mm] | [kW] | [rpm] | [kg/h] |

RS100/50 | 100 | 50 | 25 | 280 | 80 |

RS120/70 | 120 | 70 | 40 | 250 | 120 |

RS140/90 | 140 | 90 | 85 | 210 | 180 |

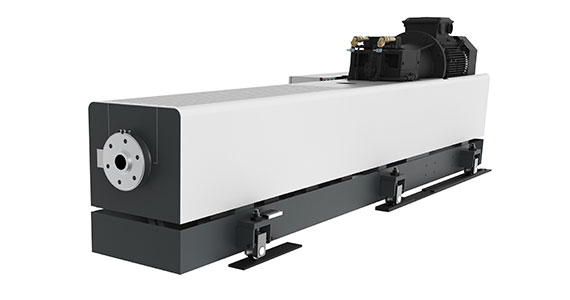

A very high plasticizing capacity is sometimes required when you process PS, PP, or LD-PE. Reifenhäuser high-speed extruders meet this requirement on an extremely small footprint owing to their high screw speed.

- Polypropylene (PP)

- Polystyrene (PS)

- LDPE

Extruder RH034-1-70-36D | Drive | Drive Speed | Plasticizing capacity PP | Plasticising capacity PS | Plasticising capacity LDPE |

[Typ] | [kW] | [U/min] | [kg/h] | [kg/h] | [kg/h] |

HS 1 | 114 | 350 | 100 – 400 | 100 – 450 | 100 – 350 |

HS 2 | 184 | 525 | 100 – 600 | 100 – 700 | 100 – 530 |

HS 3 | 264 | 700 | 100 – 800 | 100 – 950 | 100 – 700 |

HS 4 | 338 | 850 | 100 – 1000 | 100 – 1100 | 100 – 900 |

HS 5 | 378 | 950 | 100 – 1100 | 100 – 1250 | 100 – 1000 |

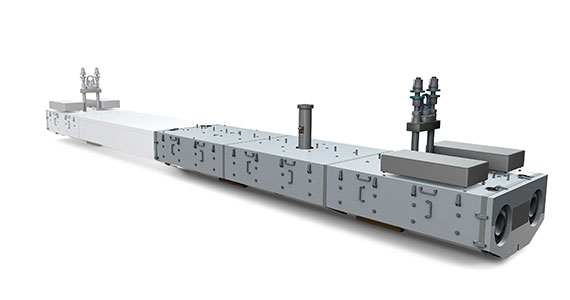

When it comes to compounding and direct extrusion, co-rotating twin screw extruders are unbeatable. Our Reitruder, for example, processes 100% recycled PET material without pre-drying, significantly minimizing energy and raw material costs.

- Polypropylene (PP)

- Polyester (PET)

- Polylactides (PLA)

- Polystyrene (PS)

- Thermoplastic elastomers (TPE)

- Thermoplastic polyolefins (TPO)

- Polymethyl methacrylate (PMMA)

- and others

Diameter ratio of the screws (Da/Di | 1.33 or 1.55 |

L/D ratio | 33 or41 |

Extruder (Ø) [mm] | 43 – 120 |

Drive power [kW] | 40 – 720 |

Throughput [kg/h] | 160 – 2,200 |

Diameter ratio of the screws (Da/Di) | 1.33 oder 1.55 |