1.

安装莱芬豪舍共挤分流器

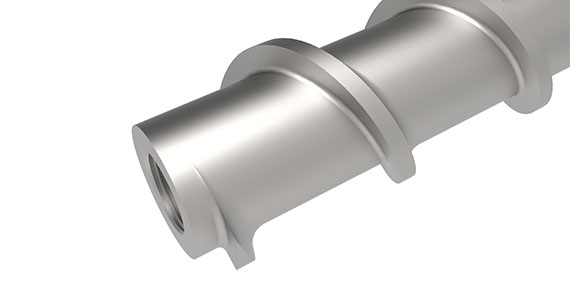

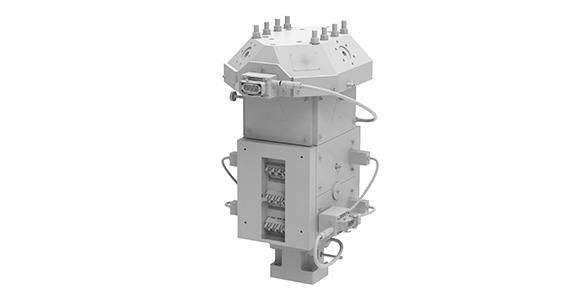

共挤分流器

用最小的公差生产多层复合材料

生产商在制造多层薄膜时,经常使用超过必要的原材料。通过精确关注层厚度来避免这种情况,并降低制造成本

准确无误地工作,提高你的利润率

你是那些因为忽略了单层公差的重要性而导致损失的生产商之一吗?每一次与理想层厚度的偏差都会不必要地增加您的制造成本。莱芬开发了共挤分流器,使您能够精确控制原材料的消耗,避免浪费,并提高利润率。

来自莱芬豪舍的共挤分流器

我们的承诺

你想生产什么?

选择您的共挤分流器

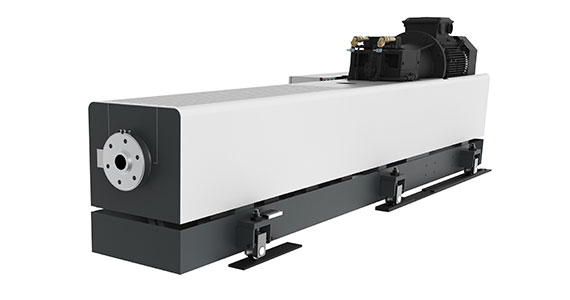

The coextrusion adapter FIX is the right solution for the production of multilayer products made of similar raw materials. High reliability combined with an easy handling characterize this coextrusion feedblock.

| Type | Coextrusion Adapter with a fixed geometry of the flow inserts |

| Number of layers | 2-5 |

| Options | Valve block for closing the covering layers to produce layer structure from A-B-A to A-B, B, B-A. |

| | |

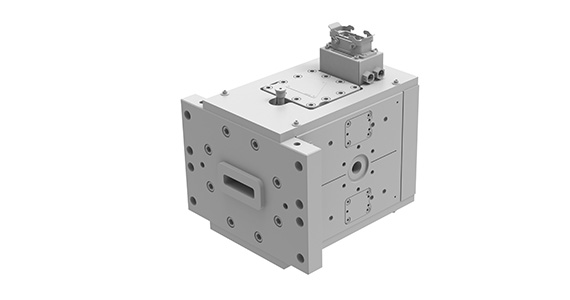

The FLEX Feedblock enables customers to make fast corrections to the flow geometry of all layers (including the middle layer), allowing for an automatic fine-tuning of shear velocity during production. The Flex provides high layer accuracy through an easy profiling system and is also recommended for the use of highly sensitve polymers due to its streamlined flow chanel design. The layer structure can be changed through an integrated channel pack.

| Type | Coextrusion adapter with easy adjustable profilers |

Number of layers | 2-5 |

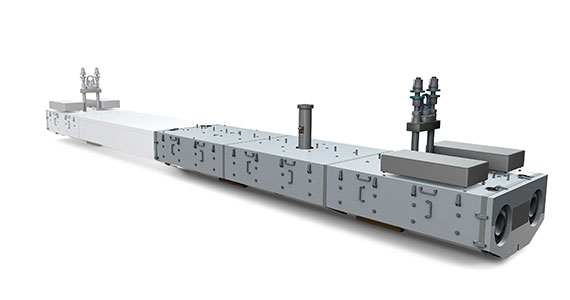

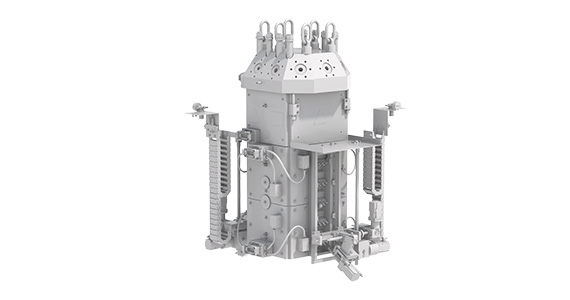

The PRO Feedblock is the best solution for the production of rheologically challenging multilayer structures with high requirements on the quality of the individual layer distribution, e.g. as needed for films and sheets with barrier functions. The patented system with adjustable segmented profilers saves time and valuable raw materials since each layer, including the middle layer, can be adjusted without a stop of the extrusion line. For an easy and fast reproducibility of the individual adjustments, index pins show the exact position of the segmented profilers.

Type | Coextrusion adapter with variable adjustable melt flow channel geometry in the feedblock by segmented profilers |

Number of layers | 3-11 (more on request) |

Options | Internal edge encapsulation for one layer: With this option the normally required additional edge encapsulation extruder as well as the edge encapsulation device of the flat die are no longer needed. This saves space and energy and simplifi es the operation of the entire extrusion line. |

The Coextrusion Adapter PRO is the only Coex System on the market that allows you to profile the individual layers while the line is running. PAM completely automates this adjustment and simplifies adjustments and optimizations through recipe management.

Recipe memory for quick adjustment while the line is running, which increases your good production and makes you less dependent on the qualifications of individual line operators. |

| Contactless adjustment while the system is running, which offers operators a higher level of work safety. |

Optimized layer distribution for reduced scrap and material usage, increasing your margin. |

Automatic profiler control for minimal setup and changeover times that improve your efficiency. |

Digital fingerprint for traceability of setting parameters, which makes it easier for you to provide evidence to your customers. |

以更大的利润率进行生产

如何从莱芬豪舍共挤分流器中获益

来自莱芬豪舍的其他组件

停止浪费材料。对层厚进行精确测量,减少你的制造成本。