How to make your line fit for the future by upgrading

"Purchasing an extrusion line is not a one-off investment, but requires continuous maintenance and the replacement of wear parts," says Daniel Matejko, Team Leader Service Sales at Reifenhäuser Blown Film. "The better a line is operated and maintained, the higher and longer line availability will be." This is why Reifenhäuser offers spare parts and maintenance services, for example, cleaning packages for customers to produce at high quality again faster, and services for refurbishing dies and coextrusion adapters.

In addition, it may be necessary to upgrade the machine. This may range from replacing individual parts to retrofitting the complete line. ”We always talk of upgrading when we modify the design of the line, not when we replace identical parts,” explains Nicolas Bröcher, Service Sales / Modifications at Reifenhäuser Cast Sheet Coating. There are a number of situations for this:

1. Securing line availability and extending service life

Although Reifenhäuser attaches great importance to long-term availability of spare parts, suppliers repeatedly discontinue components. In recent years, the product life cycle of electronic components and software especially has become shorter. Discontinued components, such as drive units, are then replaced by integrating a new version into the line control system instead of being replaced by Reifenhäuser Service on a one-to-one basis. In cases such as these, conversion is unavoidable to secure line availability and extend service life.

2. Improving performance and quality

Reifenhäuser continuously develops its own line technology. Manufacturers can benefit from these innovations by upgrading their existing equipment. For example, film is easier to print or laminate using the EVO Ultra Flat film haul-off unit, the EVO Ultra Cool 2.0 FFS equipment package increases output, and the Coextrusion Adapter Pro improves overall line efficiency. These and many other line features can be retrofitted to existing lines to help improve performance and quality.

3. Responding to new demands

When product or production requirements change, upgrades are often a good alternative to purchasing new equipment. For example, conversions from 5-layer to 7-layer lines are just as possible as switching to components that are particularly well suited for processing recyclate. In addition, many upgrades improve the energy efficiency of the line, as they comply with the latest energy efficiency classes. Digital solutions that improve OEE and monitor energy consumption can also be retrofitted to existing lines.

Upgrade early - avoid downtime

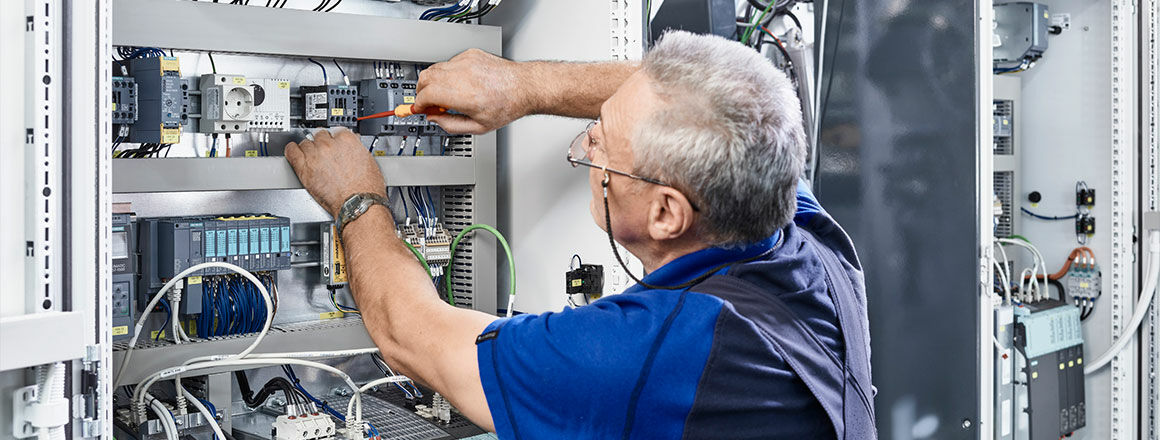

"Upgrades are worthwhile for all lines past a certain age," says Matejko, and Bröcher adds: "As machine manufacturers, we have all the expertise in-house for this and advise customers on possible upgrade packages - from electrical, process, and control systems, to software and hardware, such as extrusion dies and extruders." How long a conversion takes depends on the complexity of each case - and at present also on global supply bottlenecks for some components. "Manufacturers should therefore definitely not wait too long until the line is up and running," stresses Bröcher.

Success stories

Reifenhäuser has many years of experience in upgrading existing lines. Read how three film producers made their lines sustainable and fit for the future with Reifenhäuser upgrade packages.

Regular inspections by Reifenhäuser are one way to deal with practical upgrades early on. During these inspections, experts analyze and document the condition of a line by means of detailed checklists and identify possible wear points that can influence production processes. Matejko: "Customers receive substantiated recommendations for maintenance and upgrades from us."

Are you interested in a line inspection, maintenance or upgrade? Then contact us.

Your Flat Film Expert

Nicolas Bröcher

Your Blown Film Expert

Daniel Matejko