1.

Arrange a consultation

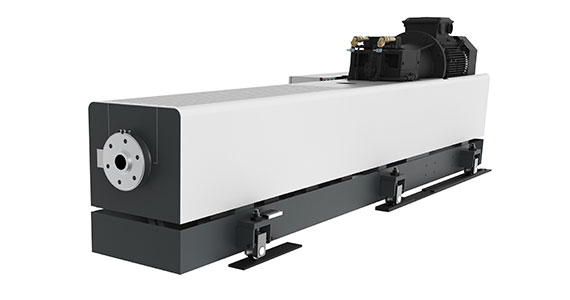

Reiloy Screws

Master production challenges with ease.

Screws that suit the application and withstand even the most wear-intensive plastics for a long time.

Please use our form to send us your request:

Do you need a personal consultation in advance?

Screws should match your goals

Are you unsure which screw you need to order to:

- prolong the life of your plasticizing unit?

- achieve the quality that exceeds customer expectations?

- process a new wear-resistant raw material?

Something to look forward to

Highlights of your Reiloy screw

Our expertise

We turn your requirements into a screw

We have over 50 years of experience in manufacturing screws that combine geometry, wear protection, and the right material pairing. Over this time we have assisted countless extrusion and injection-molding machine manufacturers and producers to reach their production targets. We are pleased to advise you and we may even surprise you with an unexpected and interesting price/performance ratio.

Together with our cooperation partners, we develop wear protection according to the latest technological findings.

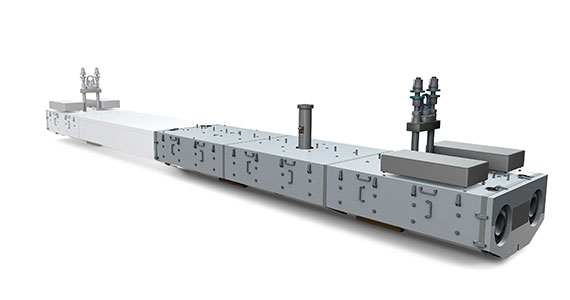

Reiloy screws compact

Key data at a glance

| Design: | Ready for installation according to your drawing or Reiloy geometry design | |

| Screw diameter: | 40 – 300 mm | |

| Length: | max. 9,000 mm | |

| Surface treatment: | plasma-nitrided, gas-nitrided, hard chrome-plated or PVD-coated |

- 3-zone screws

- multi-start augers

- Barrier screws

- Degassing screws

- Twin screws

Reiloy Screws Portfolio

From Smart to Premium

Your Options

Your requirements for the service life and cost-effectiveness of your plasticizing unit are what determines which screw is the right one for you. We guide you step by step to the best solution in a consultation.

Smart

Advanced

Premium

What would you like to produce?

Choose the right screw

For standard applications

Screws with high surface hardness

| Screw < Ø 50 | 34CrAlNi7-10 (1.8550) nitrided | |

| Screws > = Ø 50 | 34CrAlNi7-10 (1.8550) nitrided |

Depending on the application, screws can receive additional treatment, e.g., nitrided, chrome-plated, or PVD-coated.

These are recommendations; as required, some raw materials may need alternative treatment.

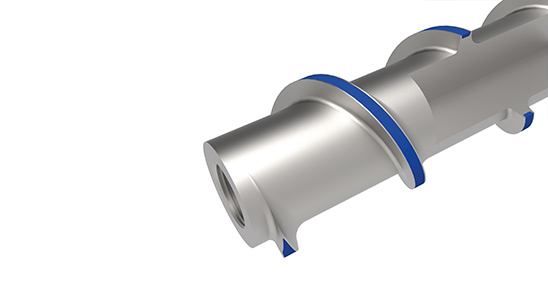

For plastics with low filler content

Plated version for high resistance to abrasive wear on flight surfaces (inlays). Corrosion and abrasion-resistant substrates depending on the application.

| Screws < Ø 50 | X 153CrMoV12 (1.2379) through-hardened | |

| Screws > = Ø 50 | 31CrMoV9 (1.8519) R331 |

Depending on the application, screws can receive additional treatment, e.g., nitrided, chrome-plated, or PVD-coated.

These are recommendations; as required, some raw materials may need alternative treatment.

For plastics with filler content of >30%

Maximum resistance to abrasive, corrosive and adhesive wear. Plated version to protect the complete flight surface. Suitable for applications to withstand extreme wear conditions.

| Screw < Ø 50 | PM-HIP through-hardened | |

| Screws > = Ø 50 | 38CrMo16 (1.2316) or 31CrMoV9 (1.8519) R341 |

Depending on the application, screws can receive additional treatment, e.g., nitrided, chrome-plated, or PVD-coated.

These are recommendations; as required, some raw materials may need alternative treatment.

For special applications

We offer special alloys for the production of complex products, such as PTFE, PFS, FEP.

Increase productive times

Save costs with excellent alloys

The wide range of alloys on the market can be confusing. Our experts guide you through the options and cooperate with you to find the alloy that is best suited for your production.

Smart

Nitriding steel: High surface hardness

| Surface hardness at room temperature | 900 – 1.100 HV5 | |

| Main alloy component | Cr, Al, Ni | |

| Structural description | Nitride-rich edge zone |

Advanced

R331 (RC3 Inlay Armoring): High resistance to wear

| Hardness at room temperature | min. 56 HRc | |

| Main alloy component | Vanadium carbides, Cr | |

| Structural description | Vanadium carbide reinforced martensitic iron-based alloy | |

| Screws up to 70 mm diameter | Design also available in through hardened tool steel |

Premium

R341 (RC3 Full Flight Armoring): High resistance to wear

| Hardness at room temperature | min. 56 HRc | |

| Main alloy component | Vanadium carbides, Cr | |

| Structural description | Vanadium carbide reinforced martensitic iron-based alloy | |

| Screws up to 70 mm diameter | Design also available in through hardened PM-HIP tool steel |

Select

RS12: Highest corrosion protection with good wear resistance - even at high temperatures

| Hardness at room temperature | min. 45 HRc | |

| Main alloy component | Cr, W | |

| Structural description | Cobalt-based alloy with tungsten mouth Chromium mixed carbides |

Optional Features

ReiMix-HS

You can optimize the mixing effect of your screw by combining it with a ReiMix-HS mixing element. The mixing element can be used for injection molding and for extrusion.

- A mixing effect enhanced by a factor up to 3 compared to a spiral shear section

- Streamlined design

- no dead zones

- short dwell time

- low pressure consumption

- small temperature increase

- Homogeneous melt

- no streaking or cloud formation

- excellent color mixing

- excellent mixing effect with different polymers

Mastering production challenges with ease

How to benefit from Reiloy Screws

The problem

Why you should not accept wear

Insufficient wear protection can become a serious problem. Loss of material on screws and barrels causes internal leakage and fluctuations in the process. This have a negative impact on product properties. In the worst case, wear and tear can even lead to production downtime, jeopardizing your profitability.

Our promise