Digital solutions in plastics extrusion

Today, plastics processors and packaging producers could be much more productive if they fully exploited the potential of digitization. Reifenhäuser, in collaboration with the tech start-up RE: GmbH, provides solutions tailored to the industry's unique needs. These solutions enable plastic processors and packaging producers worldwide in enhancing their production efficiency (OEE) and sustaining their success.

Discover how digital solutions set new standards - from monitoring and process analysis to reporting.

Reifenhäuser and RE: - strong partners for your digitization journey

Read here why Reifenhäuser and RE: GmbH are the right partners for digitizing your production.

Example 1: Insight unveiled - The lucid production

Situation: An FFS-PE bag manufacturer operates a heterogenous production site with over 30 extrusion machines from various vendors and generations. Third-party OEM tools display data for eight machines separately at each HMI. All other operational data are entered by employees on paper and processed days later in the back office. Data synchronization between systems like ERP and MES occurs sporadically through paper printouts or labor-intensive file exports and imports.

Complication: For the company, production is a black box. Employees, such as machine operators and shift supervisors, make decisions based on intuition and past experiences rather than solid data. The result is inefficient processes leading to high wastage, elevated maintenance costs, and other avoidable expenses.

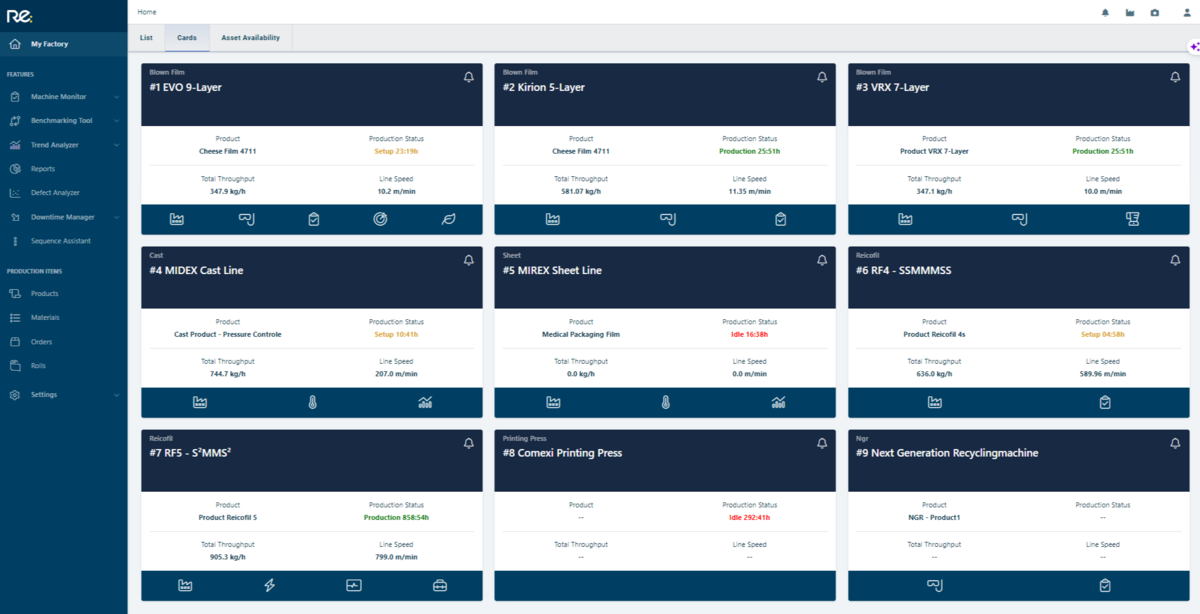

Digital Solution: The c.Hub Middleware connects all assets, peripheral devices, and subsequent units—regardless of vendor, age, or type. It captures and harmonizes all relevant process parameters in real-time, which ExtrusionOS then visualizes in clear live trends. Moreover, anyone from the team can access the data from anywhere, gaining entirely new insights into production and its challenges.

Key Benefits:

ROI Example: If the production costs for a machine are $7.2 million, increasing process efficiency by just one percent can save $72,000. The more machines connected to c.Hub and the more process steps optimized, the greater the savings.

Example 2: Monitoring & Reporting of Quality Standards

Situation: A manufacturer of high-quality PET films for food applications must meet increasing demands from customers and regulatory authorities (EFSA/FDA) to ensure product quality. Furthermore, the product portfolio is continually expanding, and customer requirements are becoming more complex.

Complication: Quality assurance is inefficient and costly. The search for errors in the process is time-consuming, and adjustments do not lead to the desired increase in OEE (Overall Equipment Efficiency). The reasons are multifaceted: During production, the machine operator only controls the parameters intermittently. If there is a critical deviation between these points in time, the operator may not notice it. Defects are often only detected during the quality control of the finished roll. Missing or incomplete data lead to incorrect conclusions and inefficient decisions by the shift supervisor, which evidently do not yield the desired results.

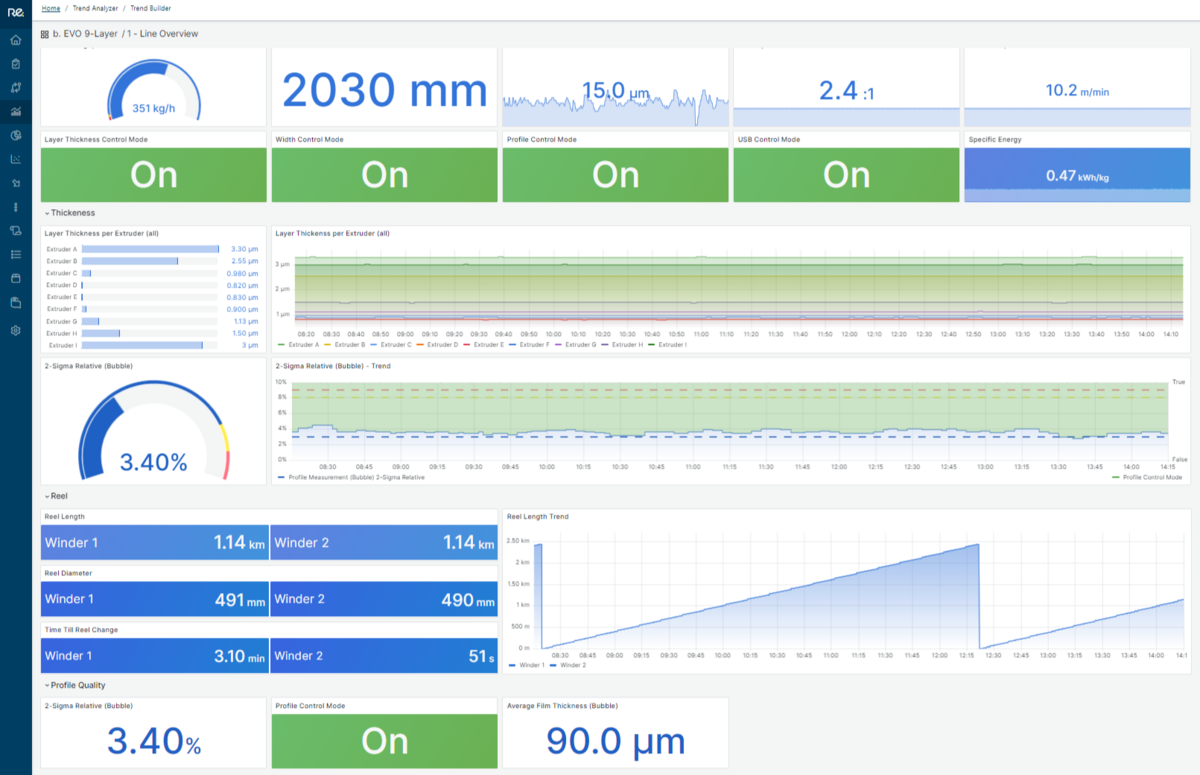

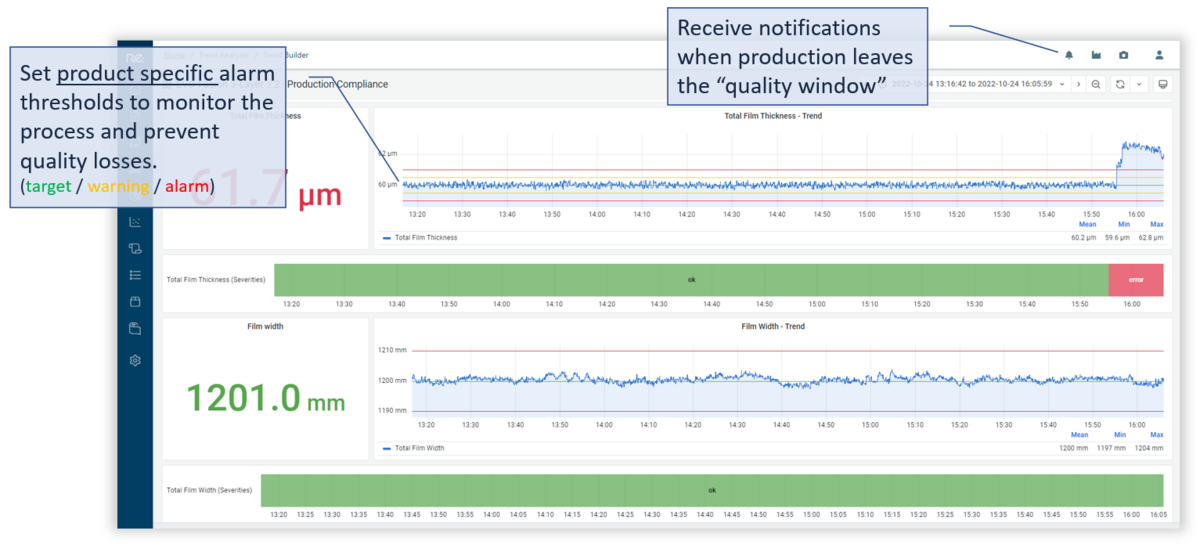

Digital Solution: The c.Hub Middleware captures all relevant process parameters of the entire production. In ExtrusionOS, all key stakeholders, from the machine operator to the shift supervisor and even the CEO, can see how production is running at any time, and this is much more precise and clear than before. To ensure they don't miss important deviations of key parameters, they can define product-specific quality windows (thresholds) in ExtrusionOS.

It is possible to monitor all key parameters and associated thresholds in real-time. Wherever they are, the production's quality status is transparent to all user groups at all times.

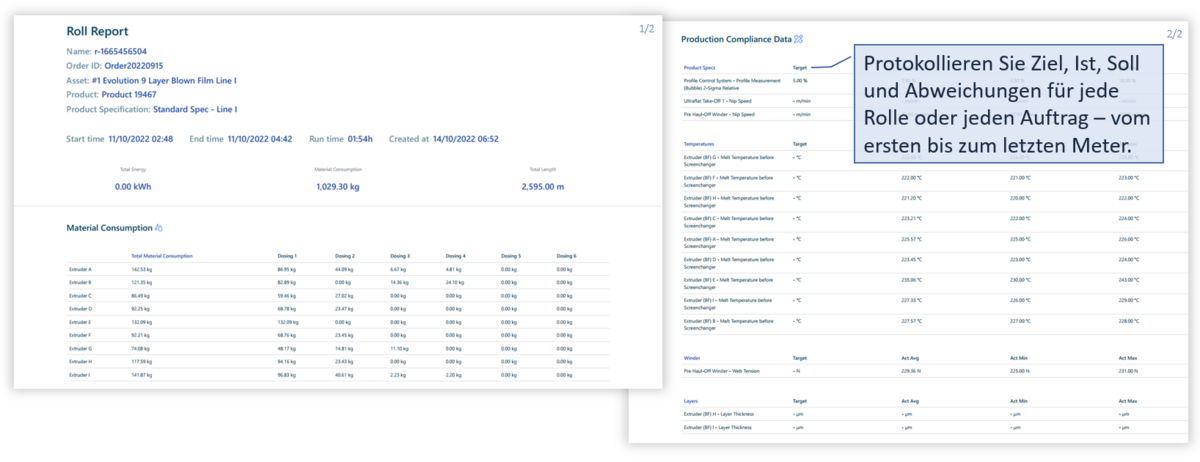

Machine operators and shift supervisors receive customized alerts and push notifications as soon as deviations from self-defined thresholds occur. Automated reporting for orders and rolls, from the first to the last meter, is also highly sought after.

Key Benefits:

ROI Example: A 9-layer blown film line has an average throughput of 550 kg/h. Production costs are $2 per kg. Suppose, for instance, the corona treater is idle or insufficiently cooled for three hours without detection, resulting in a minimum loss of $3,300 on that day because the untreated roll becomes scrap. If the roll is processed or even delivered to the customer unnoticed, the losses multiply. With the help of c.Hub and ExtrusionOS, the team would have been alerted early to parameters outside the thresholds of the corona treater and production, allowing them to intervene in a timely manner and avoid scrap and customer complaints. The better the product quality is documented, the lower the risk for the custeomer to purchase inferior films. Conversely, high transparency and comprehensive reporting boost customer trust and image.

Example 3: Minimization of Machine Downtime

Situation: A manufacturer of waste bags with recycled material content regularly experiences unplanned equipment downtime. The costs due to the limited availability of the machinery are high. The manufacturer has limited information about when, for how long, and why the machines stop.

Complication: The processes of data collection and analysis of equipment downtime are generally inaccurate and error prone. Machine operators manually enter downtime information on paper, including the causes and nature of the stoppages. In stressful situations, operators often forget to document information. The existing (incomplete) data is then manually transferred to the MES system by colleagues in the back office. Downtime data passes through multiple hands, leading to inefficient decisions based on this data, resulting in reduced equipment availability.

Digital Solution: The Downtime Manager is a feature of ExtrusionOS, developed by RE: GmbH. It allows production managers and machine operators to effectively capture and analyze downtime in the production environment. With the help of the Downtime Manager, they gain new insights that enable them to improve error analysis and reduce downtime, ultimately leading to increased overall equipment effectiveness.

Highlights of the Downtime Manager

The Downtime Manager automatically detects downtime once users have set the criteria for it in ExtrusionOS. By eliminating the need for operators to write down data on paper, data accuracy is significantly increased. Operators and production managers assign categories to a downtime in ExtrusionOS. They can do this categorization on the spot, for example via a tablet, to ensure real-time documentation. They can also generate comprehensive reports that analyze various aspects of downtime. These include, for example, the number and duration of downtime, frequency of downtime by category, and other availability metrics. The intuitive and user-friendly handling in ExtrusionOS helps the team to identify, structure and analyze downtime much more effectively.

Key Benefits:

ROI Example: The shift manager notices a pattern with the help of the Downtime Manager: Stoppages occur particularly often shortly after shift changes. The fault analysis shows that important information is lost during the handover. The company adapts its processes and trains its employees. The machine operators learn how to exploit the new data transparency in ExtrusionOS to the full and simply classify each downtime in Downtime Managers. Since then, the company has experienced 10% fewer downtimes after shift changes. Overall, asset availability can be increased by 3%, resulting in cost savings of $50,000 in the first year.