Processing recyclate depends on the components

Processing recyclate is a stress test for a plasticizing unit. Highly wear-resistant barrels and screws from Reifenhäuser Reiloy give the unit a long service life and ensure high product quality.

Whether your company is a sheet producer, injection molder or line manufacturer, processing recyclate involves many challenges because recyclate is a rather complex raw material. After all, the material has already had at least one life.

Recyclate is a bag of surprises.

It’s not always clear what additives were used when the product was first manufactured. How carefully was the feedstock sorted? How meticulously was it cleaned? Does it contain any (aggressive) residual substances? Regranulation also changes the properties of the plastic.

All these aspects can affect the quality of the recyclate. So, when recyclate is processed, special additives are added to make sure the polymer becomes a high-quality product again. Otherwise, the only option would be downcycling, i.e. manufacturing a product of lower quality than the original product.

Additives act like sandpaper.

Many additives pose a challenge for the plasticizing unit - for example, because they have an abrasive effect. Other additives tend to stick or act aggressively due to inorganic acids. Many dies and fillers also stress the components.

There are different types of wear: abrasion, corrosion, and adhesion. All of them result in surface damage.

Stress is especially high in the feed zone of the extrusion or injection-molding line, i.e. when the solid has not yet fully melted and the abrasive, corrosive or adhesive properties of the additives have a direct impact.

Recyclate: A hazard for production

Damage to the surface of the plasticizing unit during recyclate processing means it is impossible to produce high-quality material. In addition, there must be constant pressure in the system to ensure process stability, and this is not possible with damaged components. The consequence: The process is no longer controllable and, in the worst case, the line eventually comes to a standstill.

How to protect your line against wear caused by recyclate

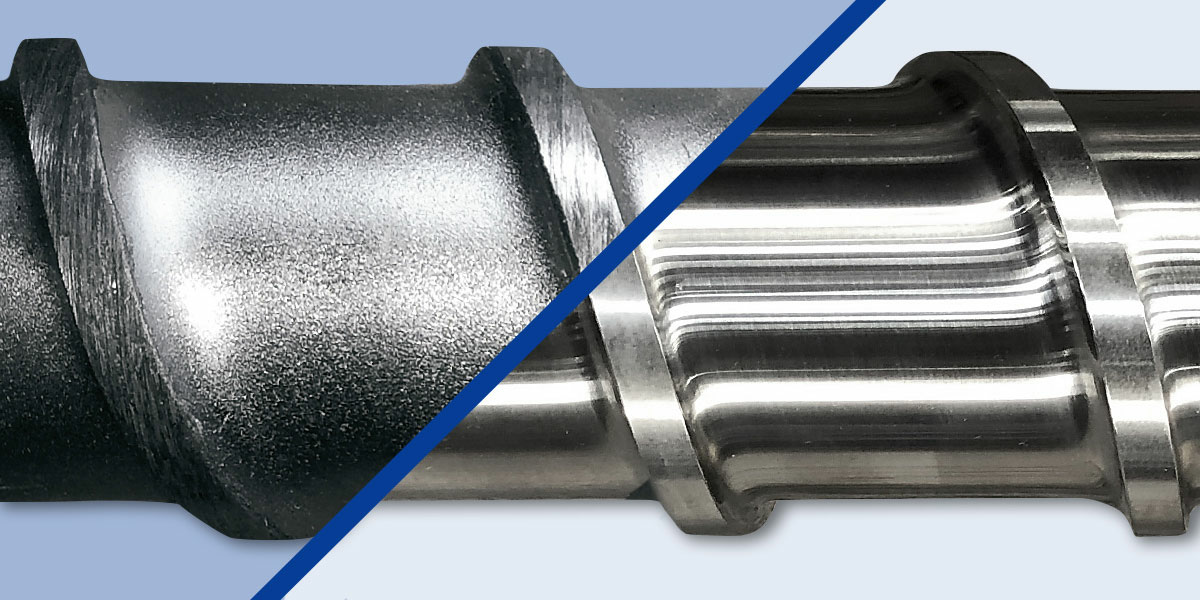

Reifenhäuser Reiloy offers barrels and screws with excellent wear protection. This allows plasticizing units to withstand adhesion, abrasion, and corrosion for longer periods, even when high-wear raw materials are processed.

Wear protection is the key to economic efficiency

Comparative studies show that wear protection pays off. High-quality components rarely need to be replaced; they produce consistent quality; and assure line productivity.

Many years of experience and all-round consulting

Reifenhäuser Reiloy has decades of experience in wear protection systems and takes a holistic approach to wear protection consulting. The Reiloy experts calculate the optimum interaction between barrel and screw cladding for each plasticizing unit and select the appropriate surface treatment.

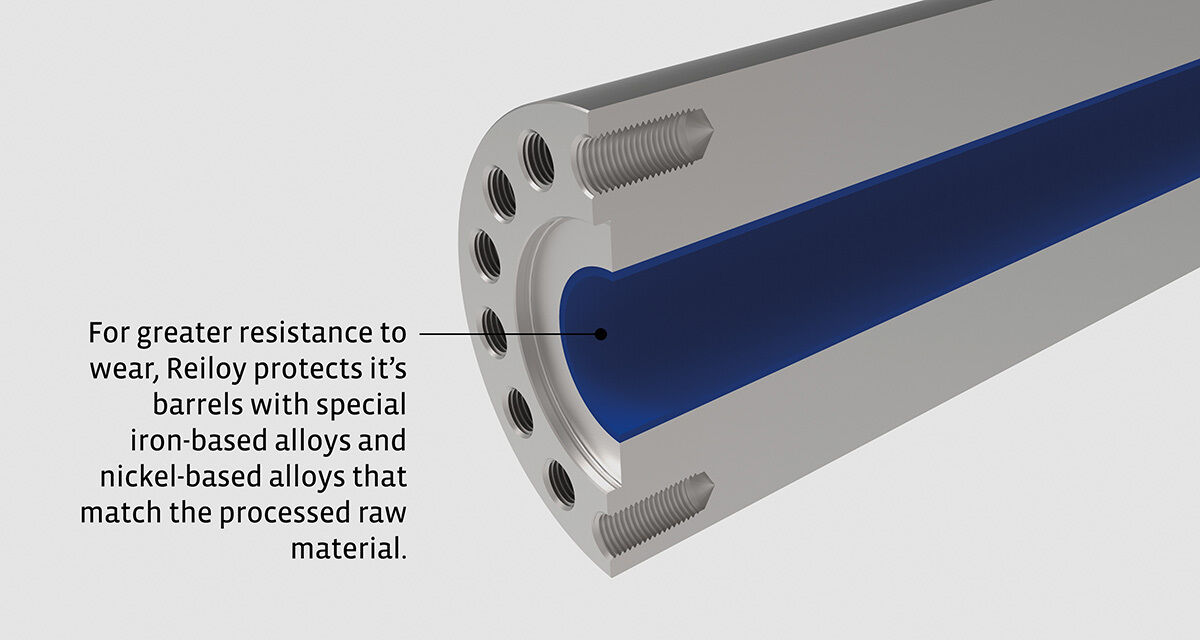

Special alloys provide powerful protection

For greater resistance to wear, special iron-based alloys and nickel-based alloys are used to match the raw material processed. The decisive factor here is the composition of the alloys. Contrary to what many processors think, wear protection does not only depend on the hardness of the coating.

Alloys and components from a single source

Reifenhäuser Reiloy is the only screw and barrel manufacturer to develop and produce its hard material alloys for wear protection in-house in its own materials laboratory - and this even includes the powders required. As a result, the alloys have a narrow tolerance window that ensures consistently high quality.