Downgauging without compromise: the new EVEREX HYBRID polishing stack

The trend in thermoforming and flat films is clearly moving toward increasingly thinner materials in order to save raw materials and costs. However, there have been limits to this so-called downgauging up to now, as the same functionality must be maintained even with less material. “With standard polishing units, polypropylene (PP) films could not be produced thinner than approx. 380 µm,” explains Nora Subel, Product Manager at Reifenhäuser Cast Sheet Coating. Thinner films previously required the use of an additional air knife, which limited the productivity of the line to a maximum of 25 m/min and resulted in losses in transparency and surface quality of the film.

Game changer for maximum flexibility

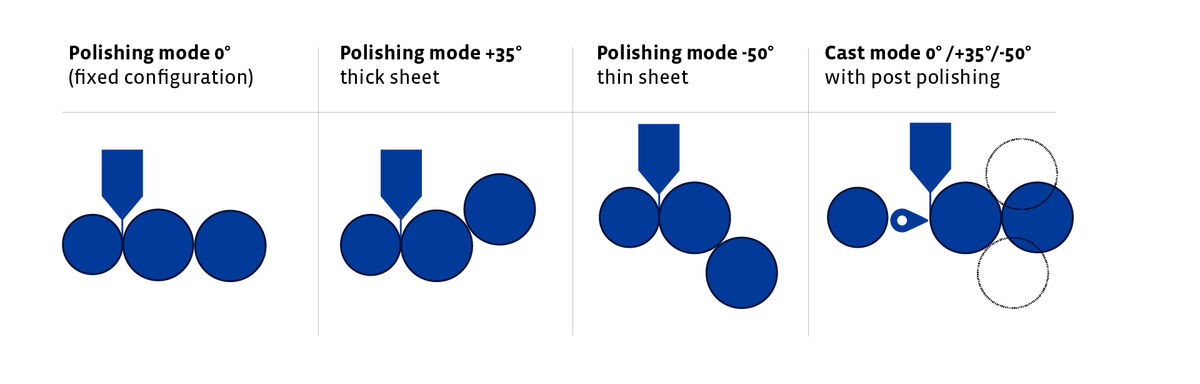

That is why the specialists at Reifenhäuser Cast Sheet Coating have now developed a new 4-in-1 polishing stack that combines the advantages of classic roller technology with an air slot nozzle. The patented EVEREX HYBRID polishing stack consists of three rollers and an air knife that can be activated as needed. “The special feature of the EVEREX HYBRID polishing stack is the flexibly swiveling third roll, which enables a wide range of film thicknesses,” says Subel.

The EVEREX HYBRID polishing stack at a glance

- Film thicknesses: 150 µm to 2500 µm

- System widths: 1000 mm to 2400 mm

- Web speed: up to 50 m/h

- 4-in-1 technology

EVEREX HYBRID polishing stack - ideal for frequent product changes

In standard polishing stack systems, however, the arrangement of the rollers is static, for example horizontal or with one roller positioned higher or lower than the others. “With the EVEREX HYBRID polishing stack, manufacturers do not have to decide on a fixed roller configuration – and therefore do not have to commit to specific film thicknesses,” says Nora Subel. "Instead, manufacturers can flexibly produce different film thicknesses without costly modifications. This is particularly relevant for thin polypropylene films, as only small rollers can create uniform cooling conditions." The third roller can be moved into different positions and, in combination with the integrated air knife, enables film thicknesses from 150 µm to 2500 µm – with just one polishing stack.

Fast product changes, high efficiency

At the same time, the EVEREX HYBRID polishing stack stands for Reifenhäuser's proven process stability. “Our goal is always to achieve maximum efficiency,” says Subel. “We want to run at the highest possible throughput that the required quality allows.” And this is exactly where the innovative technology of the new polishing stack comes in: for the production of films with a thickness of 280 µm to 350 µm, the third roll can be positioned lower than the other two rolls (see graphic, Polishing mode thin sheet). This changes the wrap angle of the film on the cooled rolls, which means that the film is cooled earlier on both sides, the cooling capacity of the calender increases, and a double web speed of 50 m/min is possible compared to conventional air knife.

Machine operators can also adjust the polishing stack quickly, easily, and precisely thanks to the mechatronic system. The process parameters required for product changes can be transferred from the recipe management system to the line within seconds. In addition, the system can be integrated into Reifenhäuser's digitalization solution, enabling transparent data acquisition in production. This allows machine operators to keep an eye on all process parameters in real time and intervene quickly if necessary.

Impressive film quality and optimal further processing

EVEREX HYBRID combines this high system efficiency with outstanding optical and mechanical film properties. Thanks to the lowered position of the third roller, the material is cooled early and evenly. The internal tension in the film is significantly reduced and the shrink behavior improved. The films produced are therefore ideal for thermal forming, e.g., for packaging in the food sector. Optionally, a tempering unit can be installed downstream to further relax the films – particularly important, for example, for highly demanding, extensively printed films that must not shrink after printing.

Benefits of the EVEREX HYBRID polishing stack

- Maximum flexibility thanks to adjustable roller

- Material savings thanks to downgauging

- High output

- High film quality and optimal further processing thanks to precise cooling

- 100% reproducible product quality thanks to mechatronic control

EVEREX HYBRID is particularly suitable for PP films with precise cooling requirements, but can also be used flexibly for other plastics. The polishing stack can be easily integrated into existing systems and is ideal for manufacturers with varying product requirements.

Interested? Feel free to contact us!