"Digitalisation is a journey, not a destination. We empower our customers to master this journey."

Reifenhäuser intends to provide plastics extrusion companies all over the world with an easy entry into digitalisation from which they can profit sustainably - regardless of company size. Reifenhäuser bases its solution on a cross-manufacturer approach that is the first to connect all installed lines and machines in a production facility.

A discussion about the concept and the added value in practice between Daniel Kajan, Director Product & Operations at RE:, Mark Schuster, PET Product Manager at Reifenhäuser Cast Sheet Coating GmbH, and Eugen Friedel, Vice President Sales and Marketing of the Reifenhäuser Group.

Mr. Kajan, what is RE: and what support does it provide producers of film and nonwovens?

Kajan: We develop digital products that enable producers of films and nonwovens to optimize their assets based on data and thus increase production efficiency. Here, we not only integrate lines manufactured by Reifenhäuser but also those of other vendors as well as all additional equipment used along the way to the end product.

RE: works closely with Reifenhäuser business units. What added value does digitalisation bring, specifically to film and nonwovens production?

Kajan: The potential of data is greater than ever before! Companies with access to all production data can quickly make processes more efficient and boost the quality of their products - a huge competitive advantage.

Friedel: Actually, the calculation is very simple. Every producer knows the price per kilo of his raw materials and how many tons of material pass through his production line every year. And he knows the power consumption of his line and the cost of each kilowatt hour. If he only increases his OEE by one percent using our digital solution, he already saves several thousand euros a year.

Schuster: Data acquisition and documentation is also essential for proof of compliance, for example, for medical products or food packaging.

If, for example, a food company complains that a product packaged in film is spoiling prematurely, it is a great advantage if the film producer can seamlessly document from the first to the last meter that he has complied with all agreed quality parameters during production. With our solution, the roll can be virtually taken apart. Customers are able to inspect the production parameters as well as quality KPIs down to the meter.

That sounds convincing. Why do some plastics converters still shy away from taking the first step?

Kajan: Because the market for digital applications is extremely diverse. Many producers find it difficult to pick out what they really need from the sheer mass of options. In a survey of our customers, 31% stated that they needed help in making their choice.

And how can Reifenhäuser provide support here?

Kajan: Digital process control and OEE optimization are core skills in the industry of the future. That's why we have built up internal know-how in this field. It has always been Reifenhäuser's philosophy that core competencies which have an enormous impact on quality, efficiency or productivity must come from within the group.

Customers benefit from the 3 T’s

These are the three pillars of Reifenhäuser's digital solutions:

- Transparency: Thanks to a clear view on all process data, OEE and quality can be improved.

- Traceability: The seamless acquisition and secure storage of all process data simplifies problem analysis and serves as quality proof.

- Troubleshooting: Customers can access their data in real time from anywhere, detect deviations precisely, react faster and thus extend machine availability.

This is why we develop all core components for our lines ourselves, such as screws, barrels or nozzles. And it’s also the reason why we now offer software solutions which we develop in-house. It is the only way we can offer digital tools that optimally support customers in their day-to-day production. With RE:, we are also significantly faster and more sustainable than external digital service providers.

Friedel: We simplify things for our customers by offering them the whole package - the digital infrastructure that goes together with the lines. Of course, an upfront investment is necessary, but our approach as a partner is to first start small with one line and quickly show the added value. Then we decide together with the customer how to proceed.

With its digital campaign, Reifenhäuser wants to set apart from other suppliers. What does that mean exactly?

Schuster: We deliberately take a different approach than other machine manufacturers who outsource the programming of their data analysis software to external providers. In our opinion, this practice entails certain risks. If a problem occurs in ongoing production, the customer first has to contact the software developer. Then he has to deal with software experts who have probably never seen an extruder before, so they first have to grasp the vital processes in film and nonwovens production and where exactly the customer's pain is.

Kajan: That's why the RE: team not only consists of software designers and machine control experts, but also process engineers - in other words, experts who know polymers through and through and are totally at home with film and nonwovens production. You will not find this pool of competencies anywhere else.Although global players like Volkswagen are now setting up their own |

What digital products do you offer?

Kajan: We sell custom solutions, rather than digital products "out of the box".Digitalisation is a journey, not a destination. We empower our customers to master this journey. We equip them with the means to retrieve production data from all machines, process it and leverage it to create real added value, namely an increase in overall equipment efficiency. This is a complex endeavor since the various machines and peripherals often use different industry protocols for control. I like to compare this to a mixed forest.

In our "3 Questions to", Daniel Kajan illustrates how film and nonwovens producers benefit from Reifenhäuser's digital services and solutions.

Why are you taking a vendor-neutral approach?

Kajan: Because customers need a solution that works efficiently for their entire mixed forest, to continue with that image. After all, they not only operate Reifenhäuser lines, but also machines and downstream equipment from other manufacturers. All these machines must be connected in order to leverage the potential of digitalisation.

Schuster: You can illustrate this quite nicely with an industry-specific example: a film-production line. After the film leaves the extruder, it is printed, shaped, and converted - only then is the product finished. So, it's not enough just to look at the data from the extruder. Besides, a machine pool like this includes equipment that has a service life of ten to twenty years. And it's no good if the newest system is digitalized, but all the others are technically stuck in the Middle Ages.

How do you deal with this situation?

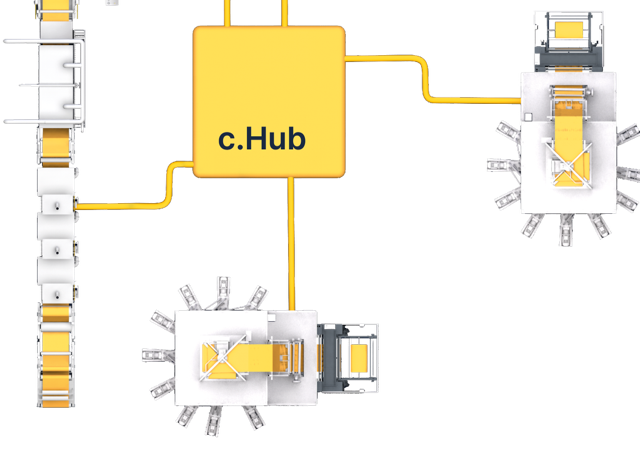

Kajan: First, our solution consists of the middleware c.Hub, which collects data from all the machines connected, standardizes it, and makes it available to other systems, for example, the ERP system ExtrusionOS is the application layer that processes this data and makes it accessible to the customer.

So, it’s something like translating different languages into a format that is universally understood?

Kajan: Exactly. Every machine has its own specific vocabulary, so to speak. We enable customers to read data in real time from different machine logs and turn it into usable information. We break down data silos that could lead to blind spots in production.

What does that mean exactly?

Kajan: It means that we not only consider the data of the extrusion line, but also that of the equipment next to it, for example cooling units, whose data is usually not gathered, but which has an impact on the process. Before, if you wanted to evaluate all of these separate data sources, you had to run from one screen to another, something that is tedious and totally inefficient.

On the other hand, our digital solutions merge all the data into one application to make it user-friendly. The c.Hub provides a shared data basis. We call this a single point of truth. So, customers conveniently find all the relevant process parameters in one place. After all, it's no use just optimizing the extruder. For example, if the temperature in the chiller is not controlled properly, the results will still be poor. That's why the producer has to keep an eye on the overall process. In the past, this was almost impossible.

Digitalisation packages from the Reifenhäuser Group

- ExtrusionOS Core & c.Hub: The basic package allows process data from all machines to be read, monitored, managed, analyzed, and saved.

- ExtrusionOS Production Compliance features the seamless tracking of production parameters from the first to the last meter.It also helps to avoid defects and customer complaints by monitoring and reliably documenting compliance with quality standards.

- ExtrusionOS Machine Health is the fitness tracker of all connected assets. It enables the early detection of wear, the optimization of maintenance intervals and thus an increase of machine availability.

- ExtrusionOS Defect Analytics: The defect sleuth correlates data from production and inspection systems, alarms when production defect occur, facilitates root cause analysis, and helps to minimize defects.

The c.Hub provides the data basis. The applications of the ExtrusionOS Suite enable customers to get the best out of this data and use it for their purposes. ExtrusionOS and the c.Hub middleware are therefore a couple - one needs the other. The customer thus needs at least ExtrusionOS Core to leverage the potential of the c.Hub middleware.

On top of that, we offer various complementary bundles for specific requirements, such as the "Production Compliance" bundle for quality assurance.

Doesn't this result in a gigantic flood of data?

Schuster: If you focus on the essential KPIs, you can keep track of everything. We advise and train customers and make it as easy as possible for them to quickly find the relevant data using filter functions. We develop software for an industry we know and for technologies we understand. That's why we can provide application- and use-case-specific tools. To put it in simple terms, check out these ten variables and then you'll know if your production is running properly.

When you say "data," you automatically think of "security" - where is the customer's production data actually located and how secure is it there?

Schuster: All data remains on the customer's servers. So, he always has control over his data and the backups. We make sure that the software is always up-to-date. Customers can decide whether they want to give us access and when, for example, for an update or for monitoring. We also offer this service to ensure the application runs on a 24/7 basis.

This means that production managers can check around the clock in real time whether everything is running smoothly?

Kajan: Yes. In principle, ExtrusionOS can be accessed from any browser-capable device. It's up to the customer to decide whether they only want to use the application within the company network or if they also wish to access their production data while sitting at home on the sofa. In fact, we know of one manager who just wants to check that all the equipment is running properly before he goes to bed - because it helps him get a better night’s sleep

Finally, a question about the future: Will digitalisation eventually replace human machine operators?

Friedel: No, that's not what we're talking about here. Our aim with our digital solutions is to assist everyone to do their jobs better, from the operator right through to the quality manager. Even an experienced line operator can become even better if he is given the right digital tool.