Cast barrier films: Save material costs thanks to innovative encapsulation solution

High-barrier films and their laminates play a central role in modern packaging technology. Over several decades, they have been continuously optimized—especially in terms of their functional barriers for reduced gas and water vapor permeability. Unfortunately, this optimization has come at the expense of recyclability, as demonstrated by the example of multi-material film laminates with aluminum. Today, the challenge is to replace these currently still widely used composites with equivalent recyclable mono-material solutions. Films with polymer-based high-barrier layers made of EVOH, as well as technical solutions in the extrusion line, play a decisive role in finding a solution.

Efficient use of EVOH

Since EVOH is still a foreign polymer in polyolefin-based barrier films, but also because of its higher price, it should be used as efficiently as possible. Just enough to ensure functionality in the packaging and only where it is really needed.

MDO technology (MDO = Machine Direction Orientation) offers an excellent solution here, as Sofija Bertasa from the Technical Sales Team at Reifenhäuser Cast Sheet Coating explains: "Even stretching EVOH-containing films in the longitudinal direction increases their barrier protection. With comparable EVOH layer thickness, films produced using the Cast MDO process therefore have better barrier properties than non-stretched films. Or to put it another way: less barrier material is needed to achieve the same level of protection." This supports the production of recyclable barrier packaging with an EVOH content of less than five percent of the total weight. This has a significant effect in terms of cost optimization and with regard to the Packaging and Packaging Waste Regulation (PPWR), which will apply in the European Union from 2030 and specifies recycling standards.

It is also crucial to keep EVOH out of the edge trim of the film, which is cut off in every casting process. Producers who succeed in doing so avoid EVOH becoming waste material. At the same time, they enable the edge trim to be recycled directly: pure PP and PE can be fed straight back into the main extruder to be reprocessed. This allows producers to save six-figure euro amounts in material costs each year and drastically reduce their internal waste volumes during film production.

High-demand packaging with barrier function

Stretched PP and PE packaging films with an EVOH barrier layer are used in flow packs (tubular bags), lidding films (lid films), and increasingly in stand-up pouches. They are primarily used to package food, cleaning agents, detergents, and pet food. “Barrier films ensure a constant atmosphere inside the packaging and active aroma protection, thus preventing odors from soaps or dog food, which people want to keep out of supermarkets,” explains Sofija Bertasa (Reifenhäuser CSC). “In addition, the stretched PP or PE prevents powdery contents from clumping by keeping moisture out. This shows that a wide variety of barriers are relevant for protecting the contents of packaging, and that it is crucial to use them responsibly and in the right amount in the right place.”

Standard solution for edge encapsulation with costly disadvantages

Edge encapsulation in the production of cast barrier films is not new and has been state of the art for decades. The standard solution for encapsulation is usually implemented within the flat die. However, it is technologically complex and has a number of disadvantages:

- In the standard solution, an additional extruder is usually connected to the die, which processes virgin PP or PE raw material and feeds it into the edges of the barrier film. This monomaterial is then cut off in the first edge trim and fed back into the barrier film process.

- The handling of the additional extruder increases the complexity of the process. It requires additional power and floor space.

- In the standard solution, the connection between the edge encapsulation and the multilayer film is highly dependent on the line speed and the interaction of EVOH, adhesion promoter, and polyolefins. If everything is not optimal here, the monomaterial cannot adhere and it comes off. - Despite good adhesion, the EVOH layer can escape at the encapsulation line, leading to contamination at the die. The associated cleaning effort increases the downtime of the system.

Reifenhäuser offers an intelligent solution already integrated in the coextrusion adapter

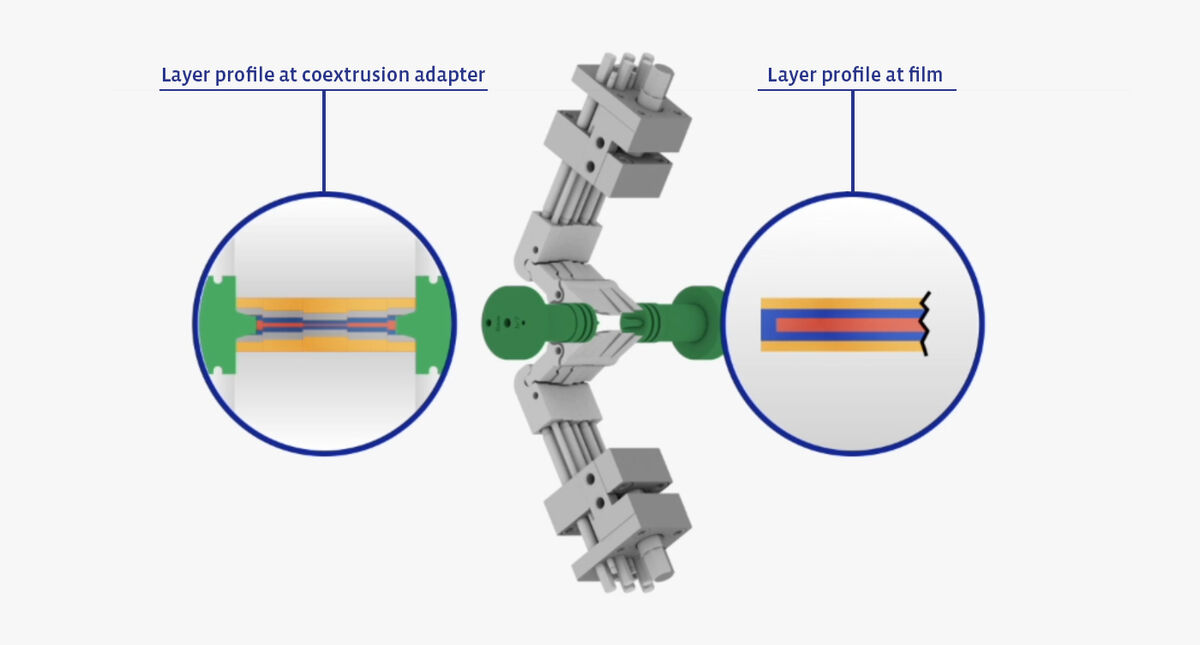

The Reifenhäuser Cast Sheet Coating (CSC) business unit is aware of these disadvantages and has developed a completely new and significantly more elegant encapsulation of EVOH for symmetrical composites: The core idea is to encapsulate the barrier and bonding agent layer not at the die, but already in the coextrusion adapter. In the adapter, the Reifenhäuser solution works with two encapsulation bolts or pins that press the barrier layer and the adhesion promoter slightly inwards at the edges. Directly below the bolts, PP or PE is then fed to the edge area and everything is heat-sealed together. This composite material then enters the die and is formed into the desired width. The result: the film edges consist of the cost-effective polyolefin monomaterial that was previously diverted in the coextrusion adapter and adhere perfectly. Neither EVOH nor the bonding agent have a chance to escape. The monomaterial edge can be easily returned to the production process.

The advantages of the patented Reifenhäuser solution for symmetrical composites compared to the standard solution:

- Works with any die principle.

- Does not require the installation of a special die, which means significantly lower investment costs. This makes it much cheaper to purchase.

- Saves production costs, as no energy is required for the additional extruder and no virgin raw material is consumed.

- Less downtime, as there is no need for time-consuming cleaning measures.

- Encapsulation bolts can be replaced within a few minutes if a product change to barrier films without EVOH is required.

The geometry of the encapsulation bolt in the coextrusion adapter ensures that the EVOH layer is pressed inwards. If films without an EVOH layer are to be run on the system, the pin can be replaced with an unprofiled version in just a few minutes.

“When customers use our encapsulation pin in the coextrusion adapter, they can save 95% of the investment costs compared to the standard solution,” emphasizes Tino Laue, Product Manager Barrier Film and Sheet at Reifenhäuser CSC. “At the same time, the process complexity of the system is reduced and the workload on operators is eased.”

Encapsulation system ideal for 7-layer film structures

Today, most of the extrusion lines installed worldwide for CPP and CPE are designed as 3- to max. 5-layer lines. These lines can be modified with an MDO unit from Reifenhäuser to open up access to new markets and applications.

A much bigger, but in this context logical step is the additional modification to a 7-layer system. This allows film producers to also tap into the high-barrier segment economically. This works best in combination with the new encapsulation system in the coextrusion adapter, because only in this case can the adhesion promoter also be encapsulated. The additional encapsulation of these two layers increases cost savings by a further 30% compared to encapsulation limited to the EVOH layer, which is possible with 5-layer systems.

“Only 7-layer lines can reliably encapsulate EVOH and adhesion promoters in the center of symmetrical composites,” Bertasa sums up. So anyone switching from a five-layer to a seven-layer line is making an investment, but the advantages of Reifenhäuser CSC's MDO encapsulation technology remain and are utilized to the fullest. This is a plus for film manufacturers who want to expand their product range to include barrier films with EVOH, which are in high demand on the market.

The encapsulation bolt ensures that the barrier layer (red) and the adhesion promoter (blue) are reliably encapsulated in the center of symmetrical composites.

For maximum product flexibility, Reifenhäuser CSC offers various geometries for the encapsulation bolt, enabling a smooth changeover between high-barrier films with EVOH and pure polyolefin MDO film structures in just a few minutes.

“The encapsulation pins are an innovative hardware add-on. Our new product does not require any additional software or complex electronics. It is a robust and easy-to-use system with a major impact on the cost-effectiveness of the line – in short, a truly smart solution,” confirms Tino Laue. Existing 7-layer lines can also be retrofitted with the new encapsulation technology.

Would you like to know how much you can save annually with encapsulation pins? Then contact us and we will calculate it for you: