At K 2025, Reifenhäuser will present an enormous range of innovations, unique automation features and digital solutions

The Reifenhäuser Group, a leading specialist for extrusion systems and components, will be exhibiting at K 2025, the world's leading trade fair for plastics processing, in Düsseldorf from October 8 to 15.

Everything at a click

Download full press kit now

Under the motto “Boost Your Performance”, the experts will demonstrate how “Automated Extrusion”, “Smart Data” and “Innovative Training” ensure performance increases and make manufacturers less dependent on highly qualified personnel.

The Reifenhäuser K 25 booths at a glance:

Hall 17 / C 22:

Reifenhäuser main booth: Blown Film | Cast Sheet Coating | Reicofil | Reiloy | Kdesign

Hall 1 / D 91:

Reifenhäuser Extrusion Systems

Hall 7 / Start-Up Zone:

R-Cycle

As usual, the Reifenhäuser main booth with over 1,200 square meters will be located in hall 17, booth C 22, where the Reifenhäuser Blown Film, Cast Sheet Coating and Reicofil business units will present their line technologies for film and nonwovens applications. For the first time, the barrel and screw unit Reiloy as well as the subsidiary Kdesign - specialist for cooling, measuring and calibration technologies for blown film lines - will also be represented at the main stand. The Reifenhäuser Extrusion Systems component unit will be exhibiting in Hall 1, Stand D91. The initiative R-Cycle, co-founded by Reifenhäuser to establish an open tracing standard for plastic packaging, can be found in Hall 7 in the Start-Up Zone.

Details on the product highlights:

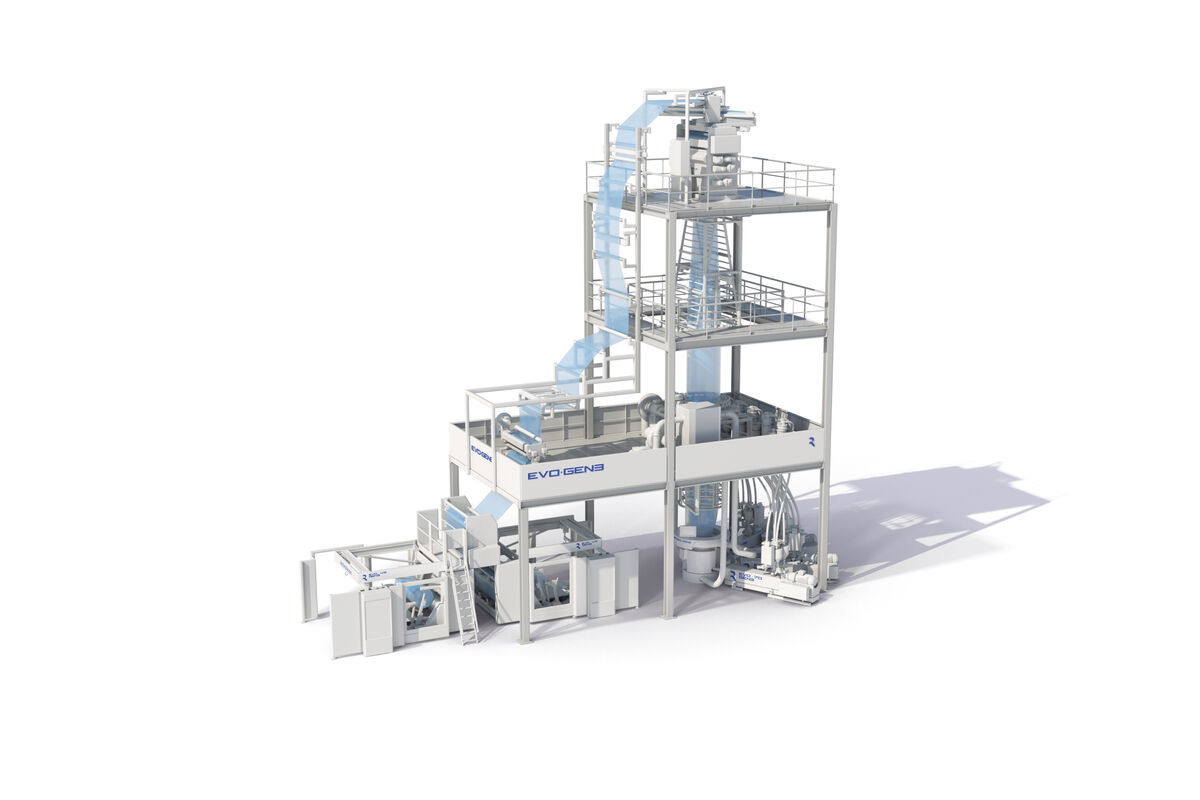

Highest output, smart automation, measurable quality: Reifenhäuser presents new EVO GEN3 blown film line

Reifenhäuser presents its new EVO GEN3 generation of blown film lines at K 2025. The technology achieves record outputs of up to 1,050 kg/h with a 350 mm die diameter and combines maximum productivity with smart assistance systems and future-proof connectivity – a decisive competitive advantage for producers in times of global skills shortages.

Up to 30 percent more output – new benchmark in the market

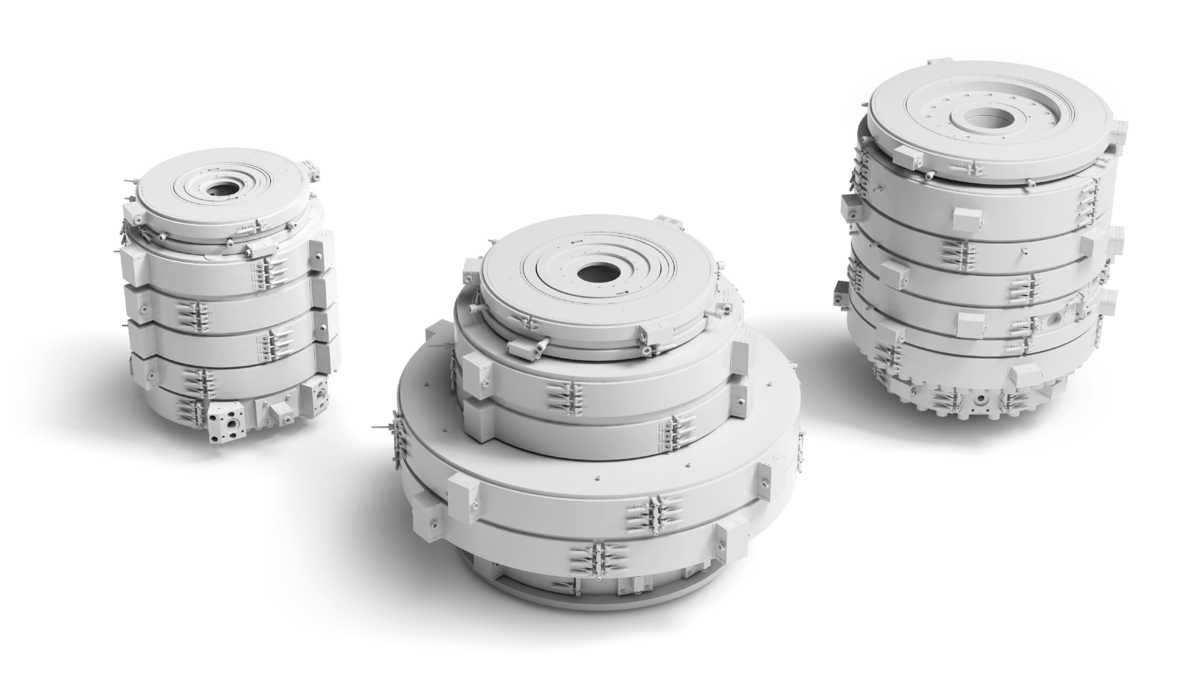

Powerful, smart, digital – Reifenhäuser is presenting its new line generation for the first time at K with these attributes and setting an impressive benchmark in terms of output. The increase of up to 30 percent compared to its predecessor is achieved through the perfect combination of the new Ultra Dies and the most advanced cooling ring on the market – the Ultra Cool GEN3. The new die heads are available in three versions: a 3- and 5-layer version for maximum throughput and fast product changes, a 7-layer version – optimized for barrier films – and a 9-layer version for the highest film quality in complex products. The Ultra Cool GEN3 features a unique IBC (Inner Bubble Cooling) stack and was designed specifically for the new 3 and 5-layer die head, but is also available as an upgrade for existing systems. The investment pays for itself in no time, especially when replacing older cooling rings, thanks to a throughput increase of up to 20 percent.

Marcel Perrevort, CSO of the Reifenhäuser Group, emphasizes: “1,050 kg/h at a die diameter of 350 mm is a real quantum leap. EVO GEN3 brings our customers a massive increase in performance and strengthens their competitive position in the long term.”

Smart automation supports inexperienced operators and beginners

Reifenhäuser understands that performance is not just about higher output. In today's competitive environment, the ease of operation of a blown film line is just as important. The shortage of skilled workers and high employee turnover make it difficult for many manufacturers worldwide to reliably achieve the desired quality and efficiency. EVO GEN3 therefore relies on smart assistance systems that enable even inexperienced line operators or newcomers to achieve perfect results at the touch of a button. These clever helpers are integrated into the completely redesigned HMI “EVO OS 3,” which guides operators to any setting in a maximum of two clicks. Thanks to customizable dashboards and a clear start-up page, it is more intuitive to use than ever before.

Auto Flat offers measurable film flatness

A unique selling point of the EVO GEN3 is the new Auto Flat system. Thanks to the Ultra Flat stretching unit, which is already well established on the market, Reifenhäuser blown film lines deliver particularly flat films that are much easier to further process, thereby saving costs. Among other things, less adhesive and ink are required for laminating and printing, which would otherwise fill the spaces in uneven films. With the new Auto Flat hardware/software solution, Reifenhäuser now makes film flatness measurable for the first time and also simplifies operation: A special sensor continuously measures how flat the film is and determines the optimal settings for the Ultra Flat stretching unit. This enables producers to effortlessly achieve perfectly flat films, making them a sought-after supplier for converters.

Towards automated factories with ReStart Assistant and digitalization

New materials such as PCR or PFAS-free PPAs increase the need for cleaning and screen changes. EVO GEN3 reduces the time required for this to a minimum: The Restart Assistant ensures that the necessary stops and restarts of the system run smoothly, quickly, and accurately. All recipe parameters are set automatically, and even less experienced operators can quickly bring the process back to full capacity.

The EVO GEN3 also features a completely redesigned control architecture for maximum connectivity, data analysis capabilities, and cybersecurity – the foundation on which producers can build more digital or even fully automated manufacturing in the future. The integration of AI-supported Reifenhäuser NEXT solutions will play a crucial role here, offering completely new possibilities in line operation – including the use of a highly specialized chatbot*.

* For details on Reifenhäuser NEXT, please refer to the separate press release.

“We are very much looking forward to presenting the new generation,” explains Marcel Perrevort. “With EVO GEN3, we are delivering a complete package of throughput, quality, and automation that offers overall equipment effectiveness (OEE) unmatched in the market.”

Powerful, smart, digital – with the EVO GEN3, Reifenhäuser presents a completely new generation of blown film lines that deliver a record output of 1,050 kg/h with a die diameter of 350 mm.

The new Ultra Dies from Reifenhäuser are available in three versions: a 3- and 5-layer version for maximum throughput, a 7-layer version optimized for barrier films, and a 9-layer version for the highest film quality in complex products.

Pictures: Reifenhäuser

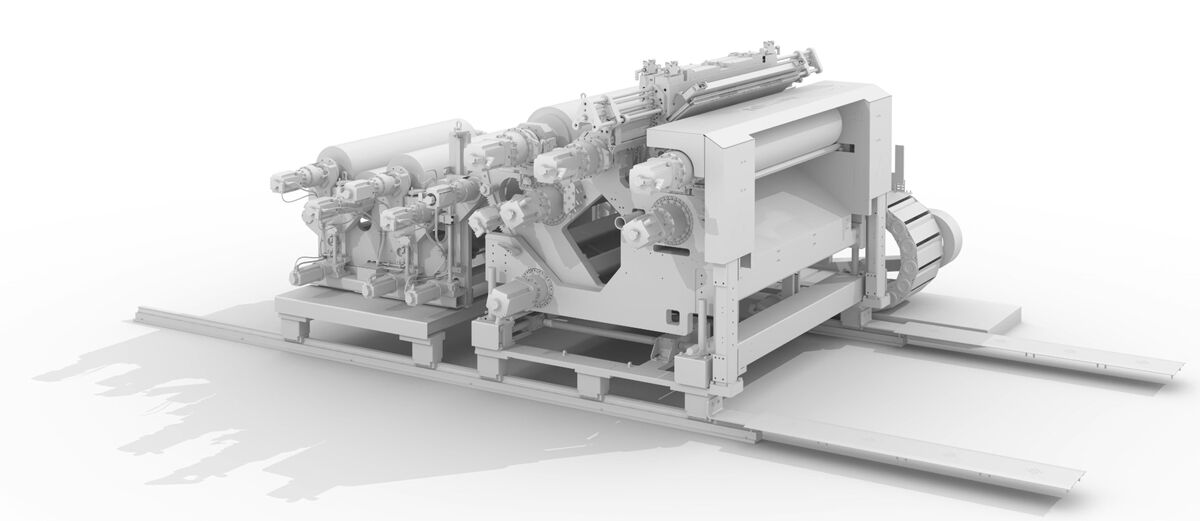

Reifenhäuser presents new EVEREX flat film line with the highest degree of automation on the market

Reifenhäuser will be presenting its new EVEREX generation of flat film lines for cast and sheet applications at K 2025. The technology offers a degree of automation that is unique in the market. From automatic PAM control of the coextrusion adapter and die to width adjustment and automated winder, the system performs numerous tasks completely autonomously – a decisive advantage in view of high staff turnover and a shortage of skilled workers.

Reifenhäuser has fundamentally revamped its flat film line technology. EVEREX is the name of the new generation, which offers one thing above all else: a huge leap forward in automation, making line operation easy, safe, and reliable even for less qualified or inexperienced operators. In addition, EVEREX enables the efficient use of barrier raw materials thanks to edge encapsulation and offers a completely redesigned HMI (Human Machine Interface) for significantly more intuitive operation. The clear dashboard layout with an intelligent color concept allows users to make flexible adjustments and impresses with a fast-reacting touch interface.

PAM 2.0 – Fully automated width adjustment

With EVEREX, errors are a thing of the past. The Reifenhäuser PAM automation option (precise, autonomous, mechatronic), which is already successfully established on the market, has been significantly expanded and now offers even more patented functions throughout the entire production process. Previously, PAM used high-precision electric actuators to control the die and coextrusion adapter fully automatically during operation. Once saved, recipes can be reliably reproduced at the touch of a button. With PAM 2.0, the systems involved in width adjustment have now also been consistently automated, thus achieving complete automation of the line. Producers can now control all quality-critical adjustments during a product change mechatronically and save up to 80 minutes compared to a manual product change, while at the same time increasing occupational safety. Product quality and the reproducibility of the process steps are also significantly increased. Precise, repeatable processes save users valuable time and reduce the potential for errors – resulting in a noticeable boost in productivity.

Best film quality and precise cutting

The automation of the width change covers four areas of the system: edge pinning and the vacuum box, as well as pre-trim and final trim. While the latter two systems are relevant for cutting the film, the first two ensure the all-important contact between the film coming out of the die and the chill roll. This is an important process step, not only to minimize unwanted constriction of the edge areas, but also to achieve high optical film properties – especially in terms of transparency. In principle, each of the four systems can be automated individually. However, the greatest added value is offered by equipping or upgrading from edge pinning to final trimming. In addition to new Reifenhäuser lines, existing lines – even those from third-party manufacturers – can also be equipped with the automation solution.

“With automated width adjustment, we integrate the necessary process knowledge directly into the machine,” explains Marcel Perrevort, Chief Sales Officer of the Reifenhäuser Group. “This enables our customers to reliably increase efficiency, quality, and reproducibility for maximum overall equipment effectiveness (OEE).”

New edge encapsulation for cast lines saves up to €150,000 per year on barrier films

In the case of flat films, encapsulating the barrier layer prevents expensive barrier raw materials from ending up in the edge areas of the film, which are cut off before winding. The edge trim can then be immediately returned to the production process. The result: the film edges consist only of the less expensive raw material, enabling producers to save an average of up to €150,000 per year in costs. Reifenhäuser EVEREX systems rely on a particularly elegant solution for this, in which the barrier layer is encapsulated not at the die, but already in the coextrusion adapter.

EVEREX HYBRID mechatronic polishing stack: Maximum flexibility and downgauging without compromise

The trend in flat films is clearly toward increasingly thinner materials in order to save raw materials and costs. However, there have been limits to this so-called downgauging up to now. With standard polishing stacks, for example, PP films could not usually be produced thinner than approximately 380 µm without the use of an additional air slot die, which in turn limits the productivity of the line.

The new EVEREX HYBRID 4-in-1 polishing stack combines three rolls and an air slot die, which can be activated as needed. The special feature is the flexibly swiveling third roller, which enables a wide range of film thicknesses from 150 to 2,500 µm. This gives producers maximum flexibility and material savings thanks to downgauging with 100% reproducible product quality through mechatronic control.

EVEREX HYBRID is particularly suitable for PP films with precise cooling requirements, but can also be used flexibly for other applications. The polishing stack can also be easily integrated into existing systems and is ideal for manufacturers with varying product requirements and frequent product changes.

“Our new EVEREX line generation offers a wealth of smart features that enable film manufacturers to simplify operation for their employees and sustainably increase their profitability,” explains Marcel Perrevort. “The high degree of automation is a clear unique selling point in the market.”

The new Reifenhäuser EVEREX flat film machine generation offers unique automation features that enable film manufacturers to simplify operation for their employees and increase profitability in the long term.

The EVEREX HYBRID mechatronic polishing stack offers maximum flexibility and downgauging without compromise.

Pictures: Reifenhäuser

Reifenhäuser showcases unique packaging solutions that combine sustainability, quality, and profitability

At K 2025, Reifenhäuser will be showcasing a wide range of end applications that perfectly combine sustainability, quality, and profitability. Together with raw material partners and packaging manufacturers, Reifenhäuser will be presenting two records in terms of output and downgauging.

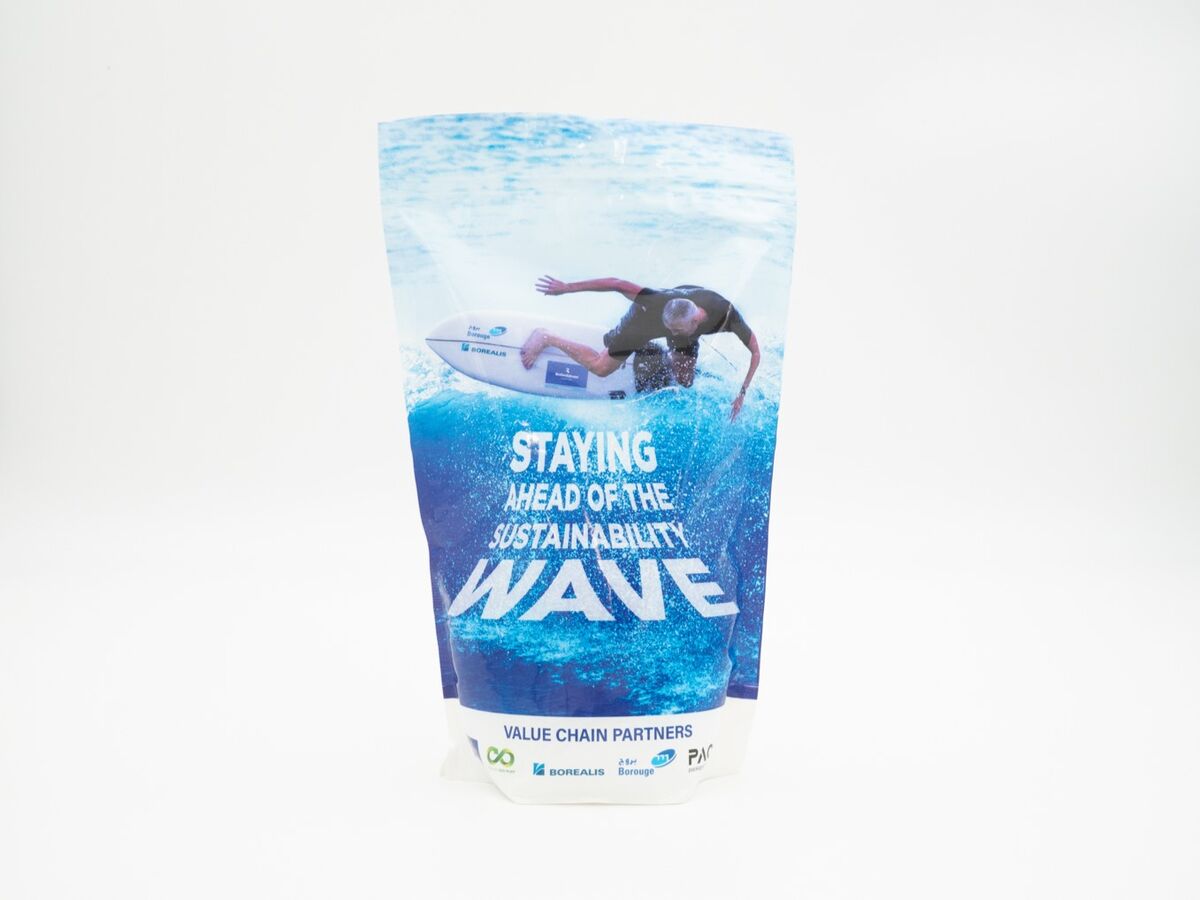

14 micrometers: the world's thinnest MDO PE blown film for sustainable all-PE pouches

Reifenhäuser Blown Film has succeeded in producing a 14 µm MDO-PE film with stable processability. Just a year ago, the extrusion specialists set a new market record with an 18 µm MDO PE film and announced further downgauging potential. This has now been impressively realized with the improvement to just 14 µm and will be presented at K 2025 in the form of a market-ready all-PE stand-up pouch. The technology behind it is called EVO Ultra Stretch – a patented MDO unit that is positioned directly in the haul-off section of the blown film line and stretches the film from the first heat. In combination with specially developed raw materials from Borouge and Borealis, this process makes the process particularly stable, which is often the limiting factor for material reduction. Ultra Stretch provides additional added value when EVOH is used for barrier films. The barrier effect of this expensive raw material is enhanced by the stretching process, so that less of it needs to be used. Overall, this reduces production costs to a competitive level compared to conventional films, which is the decisive criterion for market acceptance.

1,000 kg/h output: high-quality collation shrink film for maximum profit

With the new EVO GEN3 blown film line generation, Reifenhäuser has set a new output record for shrink film. The film is used in the logistics sector (among other areas) to bundle several individual packages – such as bottles, cans, or cups – into handy sales units. This protects the products during transport and, when shrunk under heat, ensures stable, transparent bundle packaging. Reifenhäuser uses ExxonMobil Signature Polymers for the film, which offer enhanced flow and processability as well as better mechanical performance and optics. In addition to the raw materials, the ExxonMobil Signature Polymers team also provided technical expertise in processing. With an output of 1,000 kg/h, the film is unique in the market and offers maximum profitability.

35 percent PCR content: High-performance industrial film for stretch hoods

At K, Reifenhäuser is showcasing applications with a particularly high proportion of recycled material from household waste collection (PCR). One striking example is a stretch hood film with a 35 percent PCR content. The film is a high-performance application in which a PCR content of this magnitude was previously not possible. This is made thanks to Reifenhäuser's EVO Fusion twin-screw extrusion technology, which offers an absolutely stable production process with advanced mixing and degassing. This enables film manufacturers to use PCR, even from household waste collection, to produce sustainable and profitable film that will be in increasing demand against the backdrop of rising regulatory requirements for recycled content (PPWR).

Cast MDO pouches combine recyclability and functionality

The flat film experts at the Reifenhäuser Group are showcasing, among other things, a high-performance cast all-PP stand-up pouch with a high oxygen barrier, which – in addition to excellent recyclability – also impresses with its functionality and can be manufactured particularly economically. The films for the pouch were produced on a Reifenhäuser Cast MDO line at RC-Film and further processed in collaboration with TPN Food Packaging and Wipf. Reifenhäuser's MDO technology saves material costs for barrier films through stretching, as the process enhances the EVOH barrier effect. This allows the EVOH content to be reduced to less than five percent of the total weight of the packaging, which is also a prerequisite for its recyclability.

The MDO process offers a special added value for end customers with its so-called easy-tear effect: the packaging can be torn open in one direction, as if pulled along a straight edge, and resealed using internal clips or zippers. Until now, such packaging functions in stand-up pouches were usually implemented using laser perforation, which can have a negative effect on the structure of the packaging, the barrier effect, and thus the shelf life of the packaged product. Thanks to Reifenhäuser Cast MDO technology, this property is achieved solely by stretching the film – without impairing other important film properties.

Reifenhäuser Blown Film has succeeded in achieving stable production of a 14 µm MDO-PE film for stand-up pouches.

The sustainable Cast All-PP stand-up pouches are not only highly recyclable, but also highly functional thanks to their easy-tear effect.

Pictures: Reifenhäuser

Reifenhäuser NEXT: Tackling the skills shortage and achieving operational excellence with industrial AI

At K 2025, the Reifenhäuser Group will demonstrate Industrial AI's full potential for productivity in plastics processing. At the heart of the dedicated “Reifenhäuser NEXT” brand is a powerful AI chatbot that enables even inexperienced line operators to quickly solve complex tasks in their daily work, thereby maximizing availability, productivity, and quality.

The figures speak for themselves: in Germany, 86 percent of companies are affected by the shortage of skilled workers – more than twice as many as ten years ago. The global average is currently 74 percent*. Production companies rank fifth in the industry comparison. The low availability and high turnover of experienced production specialists is one of the biggest challenges facing the plastics industry.

*Source: MPG study on the shortage of skilled workers in 2025

With Reifenhäuser NEXT, plastics manufacturers can reduce their dependence on highly qualified personnel and increase their overall equipment effectiveness (OEE) by optimizing availability, performance, and quality. This is made possible by a unique ecosystem that combines state-of-the-art AI technologies with Reifenhäuser's proven expertise and live data from production.

"Google, OpenAI, and others are already impressively demonstrating what AI solutions can achieve in the consumer sector. However, AI is only as intelligent as the data it has been trained with,“ explains Jan Karnath, Chief Digital Officer (CDO) of the Reifenhäuser Group and responsible for the NEXT brand. ”Reifenhäuser has decades of experience in plastics extrusion. We have integrated this bundled knowledge into an AI solution that is unique on the market."

The Reifenhäuser NEXT portfolio is based on three product streams that seamlessly interlock:

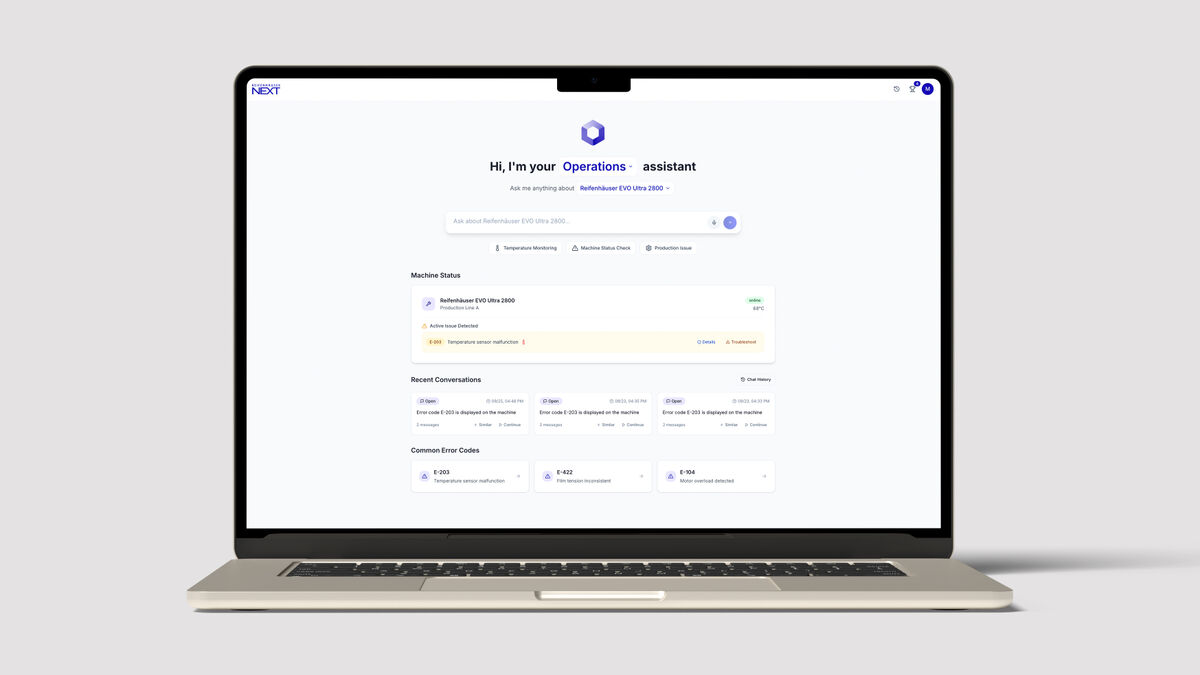

NEXT.AI – Intelligent assistance systems

At the heart of NEXT.AI is an AI chatbot that provides real-time support to machine operators and service teams during ongoing operations. The AI accesses Reifenhäuser's comprehensive expertise in engineering, service, maintenance, and process technology – and, if desired, on the user's documentation and live production data. Operators receive immediately actionable recommendations via simple text entries (prompts) in the chatbot – for example, in the event of quality problems. Thanks to this support, even inexperienced employees can achieve optimal results. This reduces downtime, lowers service costs, and makes production processes more efficient.

“Our assistance systems act as constant companions for the production teams. They not only provide quick solutions to problems, but will also deliver proactive alerts and optimization suggestions in the future,” says Karnath.

NEXT.Learning – Knowledge as the key to success

To build up and establish the necessary expertise among plastics processors in the long term, NEXT.Learning offers a combination of on-site training and a digital learning platform. This is individually tailored to the needs of customers and helps producers to retain expertise within the company despite staff turnover and make it available to new employees at any time. Thanks to the use of AI avatars, customers can access the virtual training courses in over 100 languages. On request, Reifenhäuser NEXT can also adapt and provide content very quickly to meet customer-specific requirements.

“By using natural language processing (NLP), we are democratizing specialist knowledge for our global customer base in a whole new dimension. Initial pilot projects have generated extremely positive feedback and highlight the added value of our solution – especially for international customers whose production employees speak different local languages and, for example, do not have sufficient English skills,” explains Karnath.

NEXT.Data – Generating added value from data

The third product stream, NEXT.Data, enables producers to exploit the full potential of their production data. The data is automatically aggregated via robust system integrations (e.g., OPC UA or GraphQL) and displayed in clear dashboards using the ExtrusionOS application suite. ExtrusionOS is specially designed for the requirements of the plastics extrusion and packaging industry. Among other things, customers can use it to create real-time analyses and automated OEE calculations to make data-driven decisions.

“With Reifenhäuser NEXT Product Streams, we provide our customers with a customized industrial AI journey. Depending on their requirements, we combine our NEXT.AI, Learning, and Data solutions, select the appropriate level of integration, and thus create the basis for operational excellence in line operation,” explains Karnath.

Recent studies show that the use of Industrial AI offers considerable potential for increasing overall equipment effectiveness (OEE) – with improvements of up to 15 percent. Among other things, this is made possible by reducing downtime and waste by up to 20 percent*. In addition, cost savings are expected in the area of maintenance, which can be achieved through optimized service and spare parts planning. Reifenhäuser NEXT focuses on precisely this area and supports companies in integrating the use of AI into industrial production in a targeted manner in order to fully exploit this potential and achieve sustainable improvements.

*Source: McKinsey / Deloitte

The NEXT.AI chatbot supports machine operators during ongoing operations and provides immediately actionable recommendations through simple text inputs (prompts).

By using so-called AI avatars, NEXT.Learning offers virtual training courses in over 100 languages.

With NEXT.Data, manufacturers can generate real-time analyses and automated OEE calculations to make data-driven decisions.

Pictures: Reifenhäuser NEXT

Reifenhäuser Group at a glance:

The Reifenhäuser Group at a glance

- Year of foundation: 1911

- Employees: 1.500

- Production sites: Troisdorf (Headquarter), Worms, Kabelsketal, Heinsberg, Maize (USA)

The Reifenhäuser Group is a leading supplier of innovative technologies and components for the extrusion of blown films, flat films and nonwovens. Since the early days of the plastics industry in the 1950s, Reifenhäuser has supported countless customers build successful production and become top suppliers to their industry. As a market leader and family-owned company, Reifenhäuser has specialized business units that combine their knowledge in design, process engineering, automation, digitalization, project planning, manufacturing, and logistics. Together, the Reifenhäuser Group forms the world's largest competence network for plastics extrusion technology. Even more than 110 years after its foundation in 1911, the company is 100 percent family-owned.

Reifenhäuser Blown Film: Specialists in blown film technology

With technologies and know-how along the entire value chain, the Reifenhäuser Blown Film business unit supports its customers in the economic production of high-quality blown films that are convincing on the market and ensure business success. Reifenhäuser blown film lines enable producers to face the requirements regarding recyclable products, recycled content and biodegradable plastic products, to gain speed and to use the sustainability change as an opportunity for economic success.

Reifenhäuser Cast Sheet Coating: Modular lines for the production of cast films, sheets, and extrusion coatings

In the Cast Sheet Coating business unit, Reifenhäuser develops and manufactures standardized and tailor-made cast film, sheet and extrusion coating lines, as well as individual components such as coextrusion feedblocks, cast parts, polishing stacks, and winders that perfectly match customer requirements and offer decisive competitive advantages in terms of quality, reliability and cost-effectiveness.

Reifenhäuser Reicofil: specialist for innovative spunbond, meltblown and composite lines

Reifenhäuser Reicofil is a specialist and the world's leading manufacturer of complete spunbond, meltblown and composite lines that enable producers to meet the highest quality demands in hygiene, medicine and filtration. Reicofil accompanies its customers from the planning of the production plant to the commissioning of the line and the further development of the products, thus ensuring unique quality and reliability.

Reifenhäuser Extrusion Systems: Customized components for extrusion and injection moulding

Reifenhäuser Extrusion Systems develops and manufactures tailor-made melt-guiding and forming components for extrusion and injection molding at the price of standard solutions and supports producers in manufacturing top quality efficiently and economically. Customers are guided step-by-step to the ideal component or production is carried out according to specified drawings. The portfolio includes screws, barrels, extruders, coextrusion adapters, flat dies, automation solutions, spinnerets and microcomponents. In addition, Extrusion Systems is a specialist for wear protection: Reifenhäuser Reiloy is the only supplier in the market to develop the corresponding hard alloys completely in-house.

Management

Bernd Reifenhäuser (CEO, Managing Partner)

Dr. Bernd Kunze (CTO)

Marcel Perrevort (CSO)

Ulrich Reifenhäuser (Managing Partner)

Karsten Kratz (CFO)

Headquarter: Troisdorf, Germany