Maximum performance despite a shortage of skilled workers: Reifenhäuser shows at K 2025 how film manufacturers can increase their profitability thanks to technological innovations

Everything at a click

Download full press kit now

Marcel Perrevort, CSO of the Reifenhäuser Group, explains: "Success is closely linked to continuous improvement. However, in times of shortage of skilled workers, it is becoming a challenge for many manufacturers to achieve higher performance, better quality, greater efficiency or sustainability. We will therefore be presenting innovative technologies that give producers the extra boost they need right now. Automation, data and AI play a decisive role here."

The Reifenhäuser K 25 booths at a glance:

Hall 17 / C 22:

Reifenhäuser main booth: Blown Film | Cast Sheet Coating | Reicofil | Reiloy | Kdesign

Hall 1 / D 91:

Reifenhäuser Extrusion Systems

Hall 7 / Start-Up Zone:

R-Cycle

As usual, the Reifenhäuser main booth with over 1,200 square meters will be located in hall 17, booth C 22, where the Reifenhäuser Blown Film, Cast Sheet Coating and Reicofil business units will present their line technologies for film and nonwovens applications. For the first time, the barrel and screw unit Reiloy as well as the subsidiary Kdesign - specialist for cooling, measuring and calibration technologies for blown film lines - will also be represented at the main stand. The Reifenhäuser Extrusion Systems component unit will be exhibiting in Hall 1, Stand D91. The initiative R-Cycle, co-founded by Reifenhäuser to establish an open tracing standard for plastic packaging, can be found in Hall 7 in the Start-Up Zone.

Establishing sustainability as a business model

The circular economy and CO2 reduction will also remain key topics for the entire industry at this K. Reifenhäuser will be presenting how the required recyclable products and products made from recyclate can be manufactured profitably. This is crucial for the future competitiveness of manufacturers, especially in view of the recently published PPWR (Packaging and Packaging Waste Regulation) in Europe. Marcel Perrevort says: "Producing a fully recyclable pouch is no longer the challenge. Making it profitable and competitive with conventional solutions is now the order of the day. We show technologies and film structures that enable producers to build a functioning business model around sustainability."

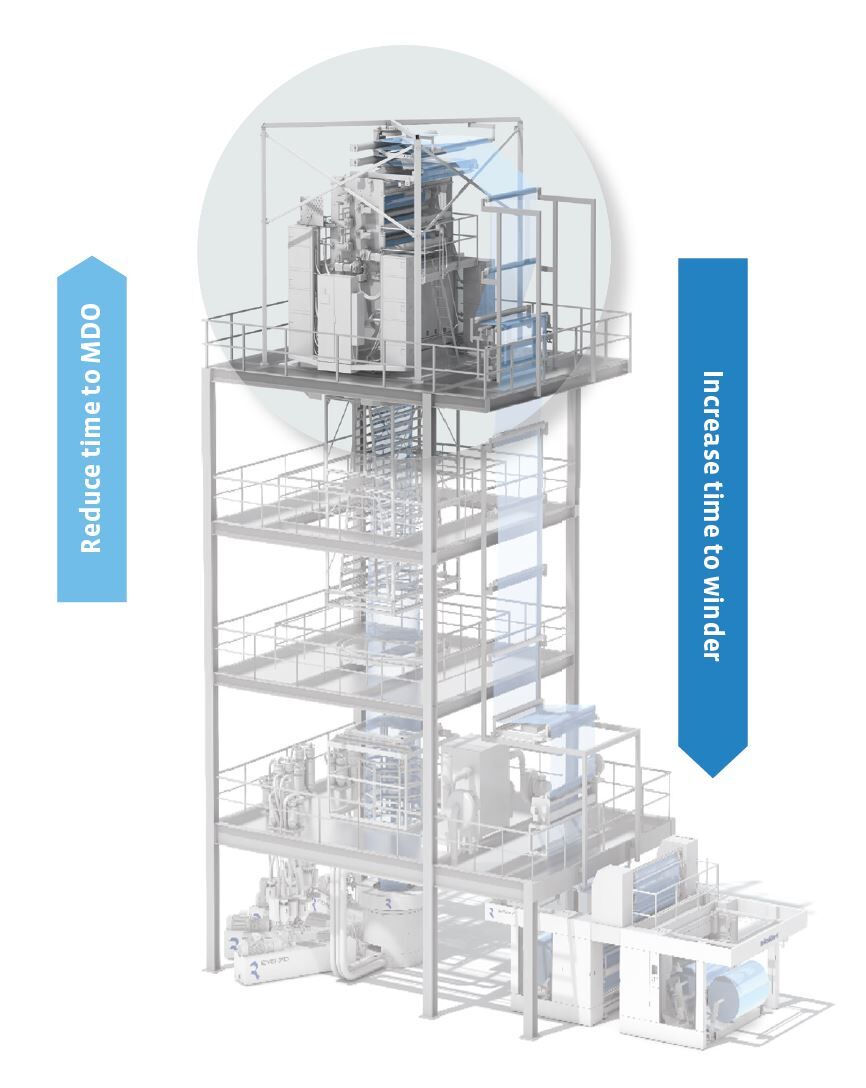

The Reifenhäuser Blown Film and Cast Sheet Coating units will be presenting their latest MDO (Machine Direction Orientation) technologies, which enable recyclable mono-material packaging by film stretching. Thanks to ever thinner film structures (downgauging) and clever technology features, Reifenhäuser systems reduce production costs to the same level as conventional products. Both business units focus in particular on barrier applications for the food, medical and hygiene sectors.

Operational excellence through automation, digitalization and training

In day-to-day production, plastics processors are often dependent on highly qualified personnel in order to exploit the full operational potential of their extrusion systems. The need for automation is therefore constantly growing. At K, Reifenhäuser is launching new developments in this area and presenting further developments of already proven automation options - above all the patented PAM system (precise, autonomous, mechatronic) for flat film lines. The automation option uses mechatronic actuators to automatically control the coextrusion adapter and die during operation. The second generation of this system, which is unique on the market, will be presented for the first time at K.

Digital solutions are another decisive factor for operational excellence. Reifenhäuser offers powerful software tools for connecting machines, data analysis and automatic process monitoring and optimization of production. In addition, Reifenhäuser provides scalable learning opportunities - for more effective training and the best possible qualification of production employees. In order to further expand its commitment to the digitalization of the plastics industry, the Reifenhäuser Group will bundle its digital and learning solutions under the Reifenhäuser NEXT brand in the future. The new business unit will focus on the seamless integration of Industrial AI and will present its new product portfolio for the first time at K.

For the exchange of packaging data across companies, Reifenhäuser is driving forward the open tracing standard R-Cycle. Producers can use it to efficiently digitize their packaging data management in order to meet the growing information requirements of the PPWR. R-Cycle can be used immediately as a software-as-a-service solution and is supported by a community of over 30 globally active companies.

"At K 2025, we will be showcasing an enormous range of innovations around our extrusion technologies and setting new performance and profitability benchmarks in the market. We will also be offering unique automation features as well as digital solutions as part of our Reifenhäuser NEXT brand launch. The K show will be the ideal stage for discussing specific applications with our customers and demonstrating concrete added value," explains Marcel Perrevort.

Details on the product highlights are available here as separate press releases:

Profitable recyclable packaging: Reifenhäuser Blown Film MDO technology makes it possible

The demand for recyclable mono-material packaging is growing rapidly - driven by regulatory requirements and the increasing sustainability demands of major brand owners. At K 2025, extrusion line manufacturer Reifenhäuser Blown Film will be demonstrating how sustainable flexible packaging can be made economically competitive with the help of Reifenhäuser MDO Ultra Stretch technology: The key lies in the combination of reliable process stability and extreme downgauging.

Marcel Perrevort, CSO of the Reifenhäuser Group, says: "The technological path towards MDO mono-material films is set - now the race for profitability begins. Thanks to its unique technological approach, our MDO unit Ultra Stretch gives manufacturers a clear competitive advantage - while at the same time ensuring the highest quality and processability of the films."

World's thinnest all-PE blown film with EVO Ultra Stretch

Reifenhäuser Blown Film has succeeded in producing the world's first process-stable 18 µm MDO PE film with further downgauging potential. The technology behind it is called EVO Ultra Stretch - a patented MDO unit that is positioned directly in the haul-off of the blown film line, that stretches the film from the first heat. This makes the process particularly stable, which is otherwise often the limiting factor for material reduction. Ultra Stretch provides additional added value when using EVOH for barrier films. The barrier effect of the expensive raw material is enhanced by the stretching process, meaning that less of it needs to be used. Overall, this reduces production costs to a competitive level compared to conventional films, which is ultimately the relevant criterion for market acceptance.

With MDO stretch units from Reifenhäuser, producers improve the mechanical film properties due to the orientation of the polymer chains in the stretch direction. This means that PET films, which usually ensure stability in film laminates, can be replaced in order to produce a recyclable mono-film composite. Mono-PE is the most common application for blown films in this regard. Stretching also makes the film thinner, which reduces material consumption. The standard thickness of MDO PE film is between 20 and 25 µm. The downgauging achieved in this way saves production costs and therefore increases profitability.

A similar raw material consumption of previous PET-PE laminates is technically achieved with blown films - due to the different densities of the PET film and MDO-PE film - if the PET film, which is usually 12 µm thick, is replaced by a 16 to 17 µm thin MDO-PE film.

“The unique technical approach of EVO Ultra Stretch offers even more downgauging potential, which we will use in combination with special formulation developments for even thinner films in the future,” says Marcel Perrevort. “At K 2025, we will set new benchmarks and show that recyclability and cost-effectiveness go hand in hand.”

EVO Ultra Stretch at K 25:

Reifenhäuser main booth – hall 17 / C 22

Reifenhäuser EVO Ultra Stretch blown film lines enable the production of mono-material laminates (all-PE film) for fully recyclable flexible packaging.

Reifenhäuser Blown Film has already demonstrated the competitive production of recyclable packaging with an 18 µm MDO PE film with market-ready product samples.

Pictures: Reifenhäuser

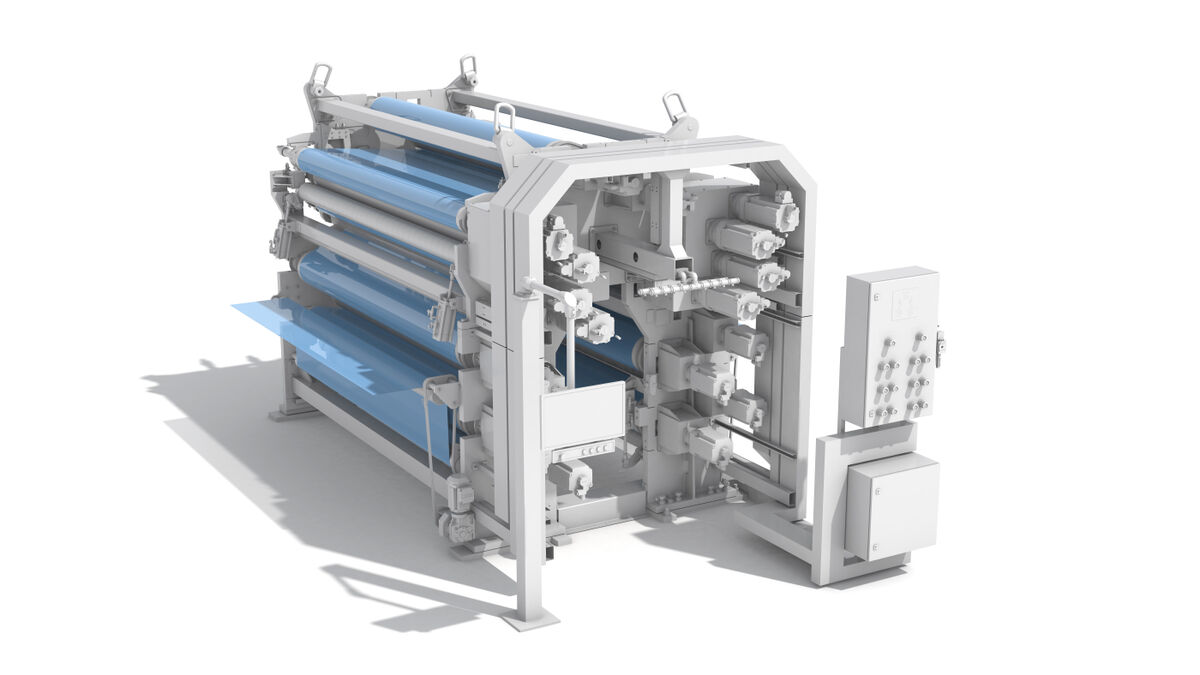

Reifenhäuser Cast MDO technology combines recyclability, cost-effectiveness and special functions for flexible packaging

At K 2025, Reifenhäuser Cast Sheet Coating, a line manufacturer specializing in flat film technology, will be demonstrating how film manufacturers can economically meet the requirements of the Packaging and Packaging Waste Regulation (PPWR) with regard to fully recyclable films and at the same time provide their customers with functional added value. Reifenhäuser's Cast MDO technology also enables the easy-tear function that is in great demand for consumer packaging and reduces the material costs of barrier films thanks to clever edge encapsulation.

With the PPWR coming into force in Europe, the demand for production technologies for recyclable mono-material solutions made of PP or PE is also growing in the cast sector. The answer is the same as in the blown film sector: MDO (Machine Direction Orientation) stretch units, which give the films extra stiffness, better optical properties and up to double barrier properties. PET films can therefore be replaced in composite materials in favor of a monomaterial solution.

Marcel Perrevort, CSO of the Reifenhäuser Group, explains: "We entered the cast MDO market at an early stage, which means that, in addition to the hardware, we have a firm knowledge of the process. Together with partners, we develop high-performance end products such as Cast All-PE stand-up pouches. As a line manufacturer, we always pursue one goal: to develop technology for recyclable films that are both functional and economical to produce. We will be showcasing the successful results at K 2025."

Clever features reduce manufacturing costs

Manufacturers who produce film for barrier packaging save material costs with MDO technology simply by stretching, because the process reinforces the EVOH barrier effect. The EVOH content can thus be reduced to less than five percent of the total weight of the packaging, which is a prerequisite for its recyclability and saves costs. Reifenhäuser cast systems also offer a further option for significantly reducing production costs: a particularly clever edge encapsulation process that eliminates the EVOH content in the film waste - without the need to invest in an additional extruder, which is necessary with other solutions. The encapsulation of the barrier layer is carried out directly in the coextrusion adapter. The result: the film edges and the resulting edge trim contain only low-cost raw material. This allows producers to save up to 150,000 euros per year on average.

Easy Tear: Pouches open exactly straight

The Reifenhäuser Cast MDO unit offers special added value for end customers thanks to the so-called Easy Tear effect: the packaging can be torn open in one direction exactly straight. It can then be closed using internal clips or zippers. Until now, packaging, such as stand-up pouches, was usually perforated in advance with a laser, which can have a negative effect on the structure of the packaging, the barrier effect and therefore the shelf life of the packaged product. With Reifenhäuser Cast MDO technology, this product property is achieved simply by stretching the film - without impairing other important film properties.

Reifenhäuser Cast MDO technology also available for retrofitting

The MDO technology from Reifenhäuser CSC is available for all in-house and almost all third-party cast systems. The unit can be ordered for new systems as well as retrofitted in the field as long as the width of the system does not exceed 3.60 meters.

"Reifenhäuser Cast MDO systems enable the production of recyclable packaging - with a barrier function if required - at low production costs. With Easy Tear, we also offer a clever technical solution that provides an attractive end customer benefit. At K, we will be using product samples to show what Cast MDO products can do for the circular economy and how their manufacture pays off for producers," says Marcel Perrevort.

Cast MDO at K 25:

Reifenhäuser main booth - Hall 17 / C 22

Reifenhäuser Cast-MDO enables the easy-tear effect, as the polymer chains are oriented in the machine direction by stretching the film.

The PP or PE monofilm becomes stiffer through the stretching process, so that PET film can be replaced in the packaging. This means that the end product is fully recyclable.

Pictures: Reifenhäuser

Reifenhäuser Technologie sets performance standards for barrier films

Reifenhäuser has three line technologies for barrier films: cast film, air-cooled blown film and water-cooled blown film. At K 2025, the extrusion specialist will be presenting its new developments, which offer higher performance and top quality at lower production costs.

Barrier films are used in a wide variety of packaging types - especially in the food, medical and hygiene industries. The desired barrier properties are achieved through a precise multilayer structure of the film and the use of special materials. The trick is to achieve a high throughput with stable quality despite complex multi-layer processes and to reduce expensive barrier raw materials, such as EVOH, to a minimum. Thanks to the three system technologies in this application area, Reifenhäuser is one of the few suppliers on the market that can advise producers on all technologies - depending on product requirements or production volumes.

Marcel Perrevort, CSO of the Reifenhäuser Group, says: "With our systems, producers are already achieving the highest throughputs with optimum quality and barrier properties. We will continue to expand this leading competitive position with our developments and introduce clever features that bring our customers measurable added value."

New edge encapsulation for cast lines saves up to 150,000 euros per year

Cast film systems are the ideal technology for high production volumes of barrier films. They also have a technical advantage. In flat film production, encapsulating the barrier layer prevents expensive barrier raw materials from reaching the edges of the film, which are cut off before winding. The edge trim can then be immediately fed back into the production process. The result: the film edges consist only of the more cost-effective raw material - producers can save up to 150,000 euros per year on average. Reifenhäuser is presenting a particularly elegant solution for this at K 2025, in which the encapsulation of the barrier layer is not carried out at the die, but already in the coextrusion adapter. This eliminates the investment and operating costs for an additional extruder, which is necessary with other solutions. The solution also speeds up the start-up process, as there is no need to set up the encapsulation extruder.

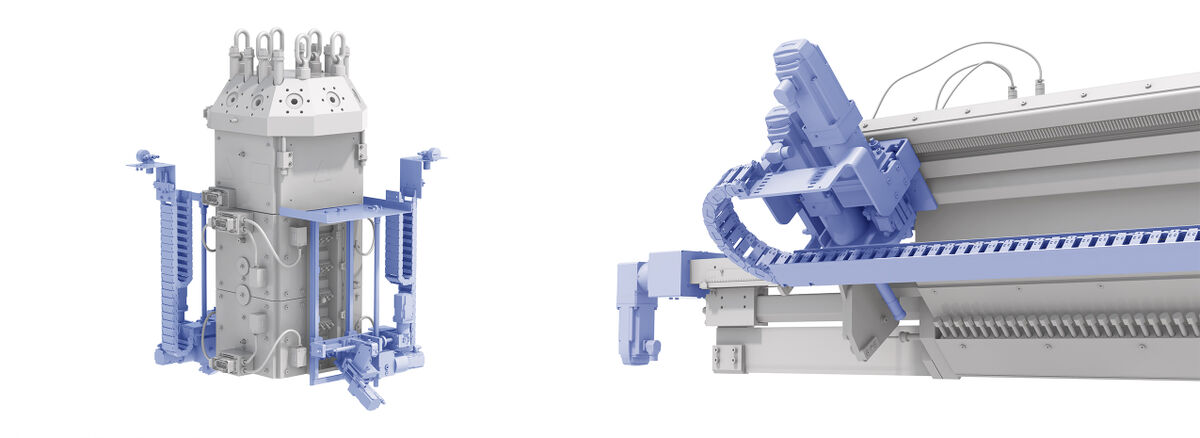

For further efficiency gains, Reifenhäuser cast lines can be automated on request with the proven PAM option (precise, autonomous, mechatronic). The patented system controls the coextrusion adapter and die via mechatronic actuators and carries out product changeovers fully automatically. Reifenhäuser is presenting a new generation of the solution at K, which will significantly increase the level of automation even further thanks to new features. Producers will thus become independent of the shortage of skilled workers and save energy as well as raw materials at the same time.

Extra powerful cooling for up to 1,000 kg/h throughput for barrier blown film

Due to their principle, blown films are suitable for smaller production volumes and, in addition to lower investment costs, offer specific advantages such as outstanding individual layer distribution. With the new developments, Reifenhäuser is significantly increasing throughput - for both PA and EVOH barrier films - from 800 to up to 1,000 kg/h, for example, with a film width of 2,600 mm. The 25 percent increase, which offers producers an enormous productivity advantage, is due in part to a new generation of cooling systems. Precise sensor technology and temperature regulation ensure bubble stability and the highest film quality at all times.

Water cooling for special film properties

For barrier applications with special requirements in terms of puncture resistance, transparency or thermoformability, it is important to keep the crystallinity of the film as low as possible. Reifenhäuser offers a special process for this: EVO Aqua Cool blown film lines. The shock-like water cooling cools the plastic melt extremely quickly, which inhibits or even stops crystallization. EVO Aqua Cool is particularly suitable for customers who require a slightly thicker film, but still attach great importance to transparency, because the thicker the film, the clearer the advantages that result from the rapid cooling of the film. Thermoforming films, lidding films, vacuum skin packaging or vacuum bag packaging are typical products in which EVO Aqua Cool shows its strengths.

"Regardless of the barrier application in which our customers operate, we have a comprehensive technology portfolio that is designed to achieve the optimum balance between maximum performance and quality. At K 2025, we will be demonstrating the specific advantages and advising on the optimum customer solution," says Marcel Perrevort.

Barrier films solutions at the K 25:

Reifenhäuser main booth - Hall 17 / C 22

Reifenhäuser has three technologies for barrier films - air-cooled blown film, cast film and water-cooled blown film - and advises customers on the optimum solution.

Pictures: Reifenhäuser

Blown film secondary cooling: Kdesign presents new CENTRO-Freeze 2 output booster

Kdesign, a subsidiary of the Reifenhäuser Group and leading supplier of cooling, measuring and calibration technologies for blown film extrusion, is presenting the new CENTRO-Freeze 2 at K 2025. The successor to the successful CENTRO-Freeze secondary cooling system sets new benchmarks in terms of cooling capacity and energy efficiency - with an even more compact design.

The CENTRO-Freeze 2 ensures a significantly better temperature reduction of the film bubble by up to 30 degrees Celsius. Where output rates were previously limited by film blocking problems, the system significantly increases throughput - by up to 25 percent. At the same time, producers can reduce or even completely avoid the use of anti-block additives. This makes the CENTRO-Freeze 2 a problem solver, especially in warm ambient conditions, low hall heights or film recipes that tend to block. The energy consumption of the CENTRO-Freeze 2 has remained the same as its predecessor despite the increase in performance.

"With the CENTRO-Freeze 2, we are setting a new benchmark for secondary cooling in blown film production. The system combines reliable technology with innovative improvements - for more performance, efficiency and continuity in film production," explains Daniel Lamers, responsible for the CENTRO-Freeze series at Kdesign.

Compact design for easy integration

Thanks to its greatly reduced height, the CENTRO-Freeze 2 can be integrated into existing and new blown film lines in a particularly space-saving configuration. The use of integrated roller guide elements replaces the traditional support cage and thus simplifies integration into systems with limited height below the flattening section.

Secondary cooling enables stable processes in hot environments

By providing additional cooling before the bubble is flattened, the CENTRO-Freeze 2 effectively prevents the film from blocking on the winder. Production process problems associated with blocking, such as the film webs sticking together when they are cut before the two winding points, are also eliminated. Even at high ambient temperatures, the production output remains constant and does not have to be reduced - for example in hot summer months.

With the integrated digital package including infrared temperature sensors, the CENTRO-Freeze 2 keeps the film temperature constant before flattening at the touch of a button and ensures a stable and reproducible process. The CENTRO-Freeze 2 also automatically follows the diameter of the bubble thanks to automatic bubble diameter tracking and replaces the supporting cage thanks to the integrated roller guide elements.

Live at K 2025 in Düsseldorf

The CENTRO-Freeze 2 is available for new and existing blown film lines from all manufacturers. Visitors can experience the system live on site at K 2025 and discuss integration, performance and individual application options with the experts from Kdesign.

CENTRO-Freeze 2 at K 25:

Reifenhäuser main booth – hall 17 / C 22

The new CENTRO-Freeze 2 combines all the advantages of its predecessor with enhanced technology for more output power with the same energy consumption and a more compact design.

Picture: Kdesign

Reifenhäuser presents new PAM generation for automated flat film extrusion

Reifenhäuser is presenting the latest generation of its unique automation solution for flat die extrusion lines at K 2025. With the new generation, the automation level of PAM (precise, autonomous, mechatronic) increases significantly. This makes producers even less dependent on highly qualified personnel and saves energy as well as raw materials at the same time.

With over 160 systems on the market, PAM is a tried-and-tested system in every respect that impresses with its unique technical approach. PAM uses high-precision electric actuators to control the die and coextrusion adapter fully automatically during operation. Once recipes have been saved, they can be reliably reproduced at the touch of a button.

Marcel Perrevort, CSO of the Reifenhäuser Group, explains: "We recognize the desire for more automation among our customers worldwide in order to ensure maximum system performance despite a shortage of skilled workers. With PAM, we offer a tried-and-tested solution whose range of functions will be significantly expanded again for K 2025. The new PAM generation will set benchmarks in terms of automation and create clear competitive advantages for both experienced producers and industry newcomers."

PAM 2.0 offers smart features and a new level of automation

The current PAM generation was first presented by Reifenhäuser at K 2022 and controls the flexible die lip and, depending on the die configuration, also the autonomous adjustment of the restriction bar, the width adjustment and the lip opening via the adjustment of the lower die lip. PAM is also available for the Reifenhäuser Coextrusion Adapter Pro. This feedblock is the only coextrusion system on the market that allows the individual film layers to be profiled while the system is running. The second PAM generation will be even deeper integrated into the overall automation of the line.

"We have developed a very precise understanding of where the challenges lie in our customers' day-to-day production. PAM 2.0 offers smart automation exactly where manual operations can slow down efficiency and quality. We are not yet giving any details about the new features, but users can look forward to a new level of automation that no one who has ever benefited from it will want to do without," says Marcel Perrevort.

PAM is available for all new flat film lines from “Reifenhäuser Cast Sheet Coating” and as a component for slot dies from “Reifenhäuser Extrusion Systems”, as well as a retrofit for dies from all third-party manufacturers. The PAM feedblock control is only available for the Reifenhäuser Coextrusion Adapter Pro.

PAM 2.0 at K 25:

Reifenhäuser main booth – hall 17 / C 22 and Hall 1 / D 91

The Reifenhäuser automation option PAM simplifies the operation of coextrusion adapters and dies. The high degree of automation makes manufacturers independent of the shortage of skilled workers.

Picture: Reifenhäuser

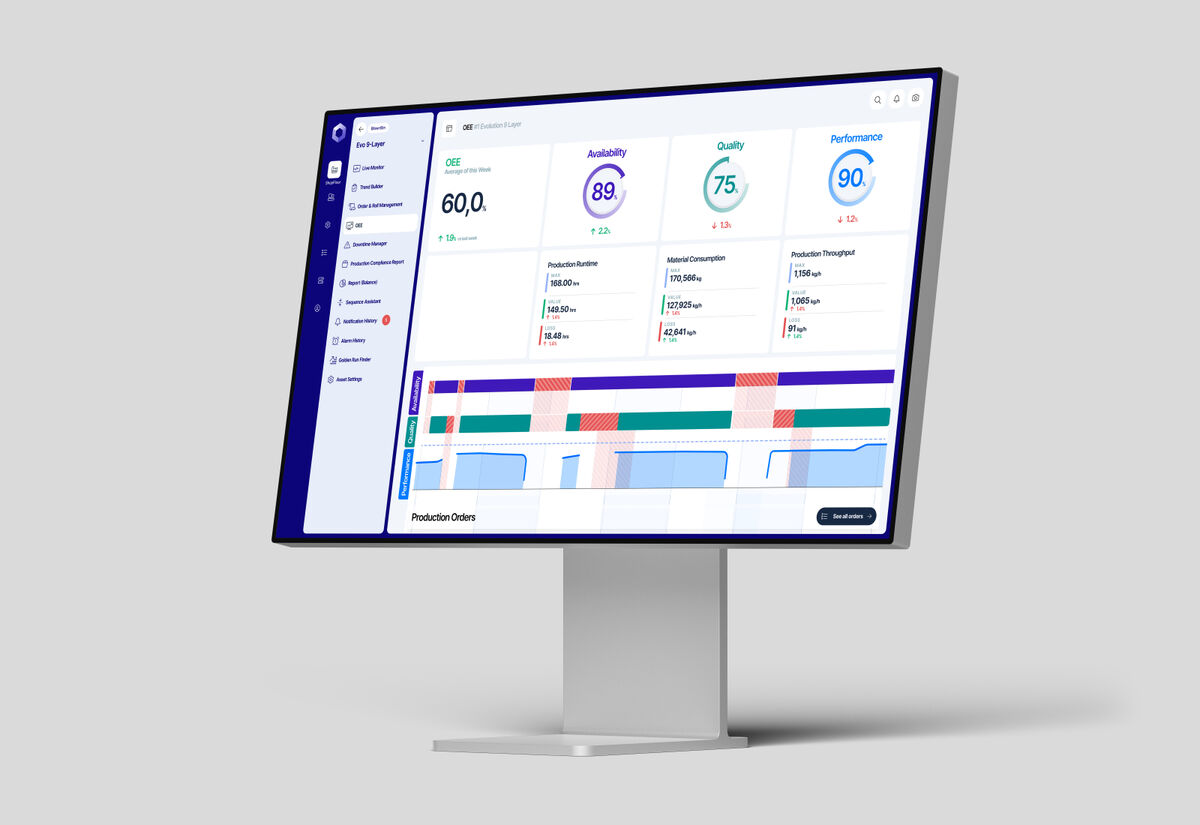

New business unit: Reifenhäuser NEXT brings Industrial AI directly to the customer

With a clear focus on AI-supported systems, the Reifenhäuser Group is now bundling its expertise in digitalization and learning under the new Reifenhäuser NEXT brand. The independent business unit brings industrial AI directly into the production halls of global manufacturers.

Reifenhäuser NEXT will be presenting its three modular product streams NEXT.AI, NEXT.Learning and NEXT.Data for the first time at K 2025. They enable manufacturers worldwide to integrate artificial intelligence quickly, efficiently and precisely into their production processes. Whether process optimization or real-time quality assurance - the NEXT solutions can be seamlessly integrated into new and existing systems, deliver measurable efficiency gains and make manufacturers less dependent on the ever-increasing shortage of skilled workers. Reifenhäuser Next relies on a team of proven AI and data experts who are already working with customers worldwide.

Jan Karnath, Chief Digital Officer (CDO) of the Reifenhäuser Group, says: "Industrial AI will be a decisive game changer for global manufacturers. With Reifenhäuser NEXT, we are bringing these technologies directly into the production halls of our customers and thus sustainably increasing productivity and competitiveness."

Current studies show enormous potential for AI solutions

80 percent of Fortune 500 companies are already using Generative AI (McKinsey). The market for industrial AI will grow to around 48 billion USD by 2030 (The Research Insights). 54 percent of machine operators want digital assistance (Capgemini) - clear signals for a new era of productive digitalization.

"With Reifenhäuser NEXT, we are responding to this market demand and offering scalable AI models, targeted training concepts and a robust data infrastructure. The aim is to give our customers a pioneering role in the next industrial revolution - from planning and implementation to ongoing operation," says Jan Karnath. "A key driver for these technologies is the increasing global shortage of skilled workers. With our Reifenhäuser NEXT solutions, we are making plastics producers less dependent on highly qualified personnel."

At K 2025, Reifenhäuser NEXT will be represented with its solutions and the corresponding product demos in hall 17, booth C22 of the Reifenhäuser Group.

Reifenhäuser NEXT at K 25:

Reifenhäuser main booth – hall 17 / C 22

Process optimization or real-time quality assurance - NEXT solutions can be seamlessly integrated into new and existing systems.

Reifenhäuser NEXT makes plastics manufacturers less dependent on highly qualified personnel with digital training concepts.

Pictures: Reifenhäuser NEXT

Reifenhäuser Group at a glance:

The Reifenhäuser Group at a glance

- Year of foundation: 1911

- Employees: 1.500

- Production sites: Troisdorf (Headquarter), Worms, Kabelsketal, Heinsberg, Maize (USA)

The Reifenhäuser Group is a leading supplier of innovative technologies and components for the extrusion of blown films, flat films and nonwovens. Since the early days of the plastics industry in the 1950s, Reifenhäuser has supported countless customers build successful production and become top suppliers to their industry. As a market leader and family-owned company, Reifenhäuser has specialized business units that combine their knowledge in design, process engineering, automation, digitalization, project planning, manufacturing, and logistics. Together, the Reifenhäuser Group forms the world's largest competence network for plastics extrusion technology. Even more than 110 years after its foundation in 1911, the company is 100 percent family-owned.

Reifenhäuser Blown Film: Specialists in blown film technology

With technologies and know-how along the entire value chain, the Reifenhäuser Blown Film business unit supports its customers in the economic production of high-quality blown films that are convincing on the market and ensure business success. Reifenhäuser blown film lines enable producers to face the requirements regarding recyclable products, recycled content and biodegradable plastic products, to gain speed and to use the sustainability change as an opportunity for economic success.

Reifenhäuser Cast Sheet Coating: Modular lines for the production of cast films, sheets, and extrusion coatings

In the Cast Sheet Coating business unit, Reifenhäuser develops and manufactures standardized and tailor-made cast film, sheet and extrusion coating lines, as well as individual components such as coextrusion feedblocks, cast parts, polishing stacks, and winders that perfectly match customer requirements and offer decisive competitive advantages in terms of quality, reliability and cost-effectiveness.

Reifenhäuser Reicofil: specialist for innovative spunbond, meltblown and composite lines

Reifenhäuser Reicofil is a specialist and the world's leading manufacturer of complete spunbond, meltblown and composite lines that enable producers to meet the highest quality demands in hygiene, medicine and filtration. Reicofil accompanies its customers from the planning of the production plant to the commissioning of the line and the further development of the products, thus ensuring unique quality and reliability.

Reifenhäuser Extrusion Systems: Customized components for extrusion and injection moulding

Reifenhäuser Extrusion Systems develops and manufactures tailor-made melt-guiding and forming components for extrusion and injection molding at the price of standard solutions and supports producers in manufacturing top quality efficiently and economically. Customers are guided step-by-step to the ideal component or production is carried out according to specified drawings. The portfolio includes screws, barrels, extruders, coextrusion adapters, flat dies, automation solutions, spinnerets and microcomponents. In addition, Extrusion Systems is a specialist for wear protection: Reifenhäuser Reiloy is the only supplier in the market to develop the corresponding hard alloys completely in-house.

Management

Bernd Reifenhäuser (CEO, Managing Partner)

Dr. Bernd Kunze (CTO)

Marcel Perrevort (CSO)

Ulrich Reifenhäuser (Managing Partner)

Karsten Kratz (CFO)

Headquarter: Troisdorf, Germany