1.

Arrange a consultation

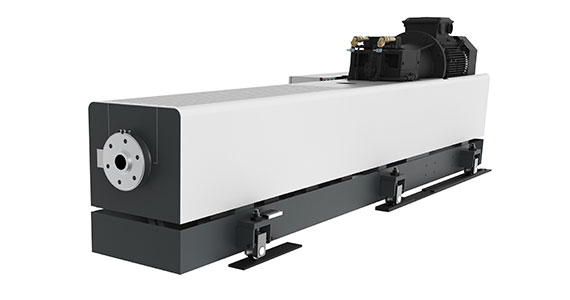

RF Smart Spunbond

Produce profitably for upcoming markets.

Standardized spunbond lines for smaller markets with short return on investment.

For smaller markets, less is more

Producers who produce for smaller or emerging markets have often had a hard time. Nonwoven lines that produce good quality are often too large of an investment and deliver too much capacity. Reicofil has developed the RF Smart spunbond line to make it easier for you to enter such markets securing a quick return on investment.

Clevere Features

Highlights of the RF Smart spunbond line

Optional features

How to use the full potential of your RF Smart spunbond line

Thanks to smaller invest:

Easier

Entry

With RF Smart plants you reduce your investment costs and start production faster because the plant is highly standardized and can be integrated into your existing empty buildings.

Thanks to top quality:

High

Sales prices

Your RF Smart line produces nonwovens of the highest Reicofil quality - ideally suited for hygiene and medical applications.

Thanks to moderate capacities:

Profitable

Production

High capacities are only advantageous in large markets. The RF Smart system is adapted to the requirements of smaller markets, ensuring you profitable local production.

Thanks to reliability:

Fast

Payback

Your RF Smart equipment is as reliable as any RF equipment: at least 8,200 annual production hours. Guaranteed. Count on predictably high productivity and reasonable payback time.

RF Smart Spunbond Line Compact:

The most important data at a glance

| Configurations | S, SS, SSS |

| Line widths | 1600, 2400, 3200 |

| Max. Speed | 800 m/min (on conveyor belt) 880 m/min (on winder) |

| Max. specific throughput | 180 kg/h/m |

| Basis weight | 8 - 70 gsm |

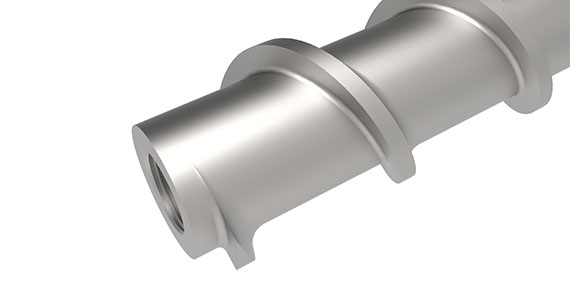

| Titer range | 1.5 – 2 den (normal PP) 1.1 – 1.5 den (Metallocene) |

| Raw materials | PP, PE |

| Bico-Technologies | optional |

| Semi High Loft, High Loft | optional |

Optional features

How to use the full potential of your RF Smart spunbond line

More features or extra convenience? Choose from optional technologies and packages to customize the line for specific needs.

Digitization

For smarter production

Your line is constantly producing valuable data. Don't let this potential lie dormant any longer. Our digital features help you produce more conveniently, profitably and intelligently.

- Machine control

- DRS Dashboard

- DRS System Basis Module

Bico

For the combination of two raw materials in one fibe

The BiCo spunbond process combines two different raw materials in one fiber, opening the door to product properties that are unattainable with monofibers - for example, the combination of superior strength and formability.

Semi High Loft / High Loft

For soft and voluminous nonwovens

With Reicofil Semi High Loft and High Loft technology, you make products that combine stability with a soft surface. Ideal for hygiene applications (e.g. topsheet, backsheet, leg cuff, cuffs).

Efficiency

More time for really important things

- Automatic press roll cleaner

- Automatic belt cleaner

- Automatic die inspection system

Ensure profitability

Reicofil Service

We help you achieve long-term production success and support you in expanding your business with existing equipment. We are at your side with support, advice, know-how and services - in person, by phone and remotely. Do you already know the following services from us?