1.

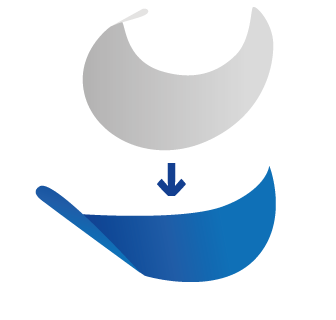

Equip blown film line with EVO Ultra Flat.

Film haul-off unit with patented, integrated flatness package for perfect blown film

Convert blown film with greater efficiency and at reduced costs: Gain a clear competitive edge for printing and laminating with perfect blown film with no flatness defects or camber.

Did you know that the flatness of your blown film significantly influences performance and cost-effectiveness in conversion processes? If you produce blown film with flatness defects or camber, the print speed must be reduced, the print image is poorer, and adhesion is worse during lamination. This means you consume unnecessarily more adhesive when laminating to other films and produce wider borders that can be easily avoided. With EVO Ultra Flat, you produce blown film that is up to 40% flatter and this means a faster ROI for you and your customers.

Flat blown film with EVO Ultra Flat

Performance and cost-effectiveness

+ 30

Advantage 2

Advantage 3

- 30

- 20

- 10

TESTIMONIAL

THE TECHNOLOGY

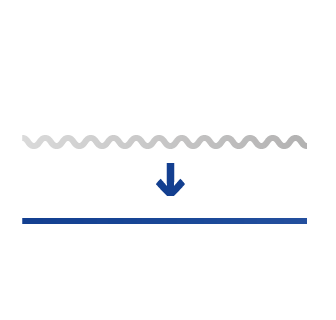

Other flatness systems on the market are positioned upstream of the winder. Ultra Flat is positioned directly behind the two-roll haul-off. Only this unique and patented position permits stretching using initial heat - to your advantage.

Discover more EVO Ultra features