want special functions and high film performance.

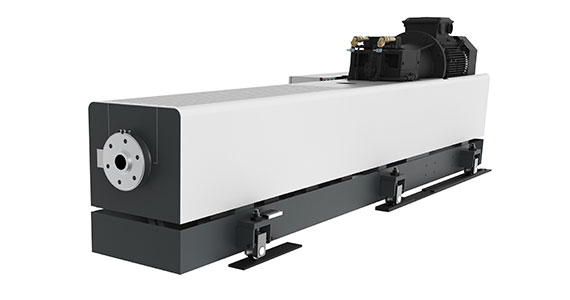

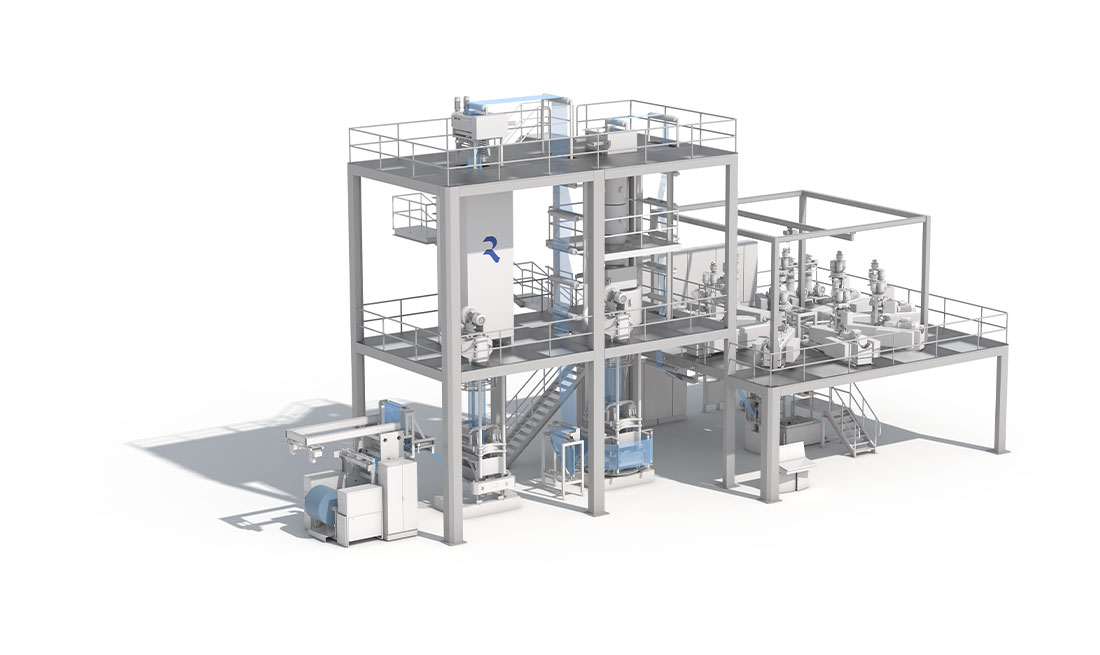

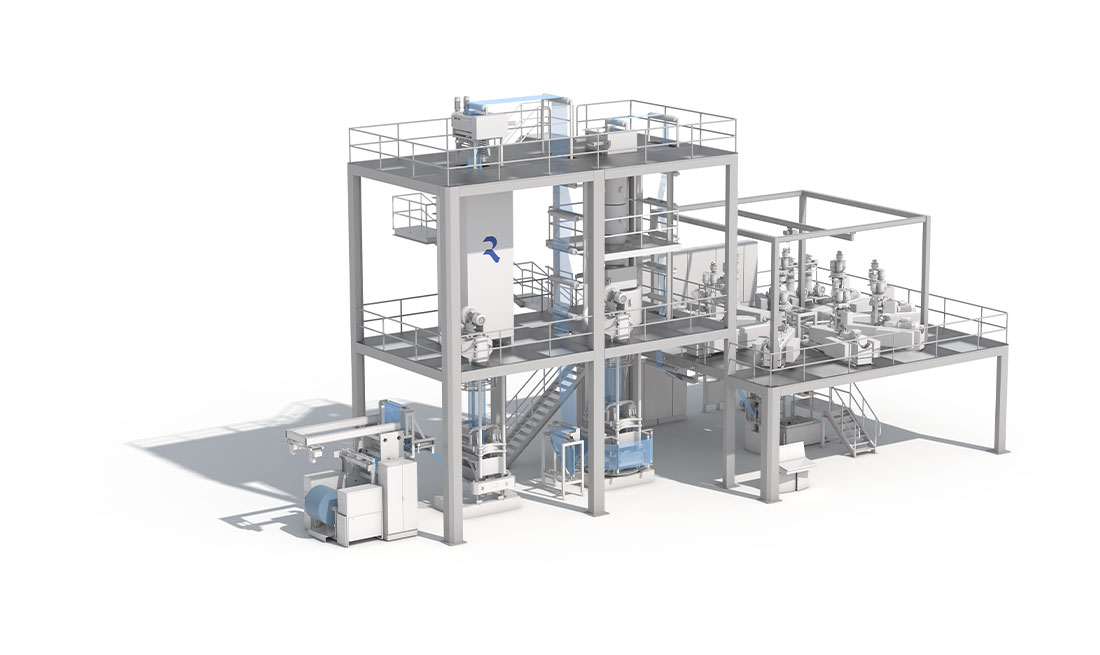

EVO Multi Bubble

Biaxial-oriented film in one operation.

By blowing the bubble multiple times we achieve a simultaneously biaxially oriented and annealed blown film where you can achieve very special properties for your end product - all within one production process. With our Multi Bubble technology you benefit from decades of development work for the optimal stretching of thermoplastic polymers - for the highest optical and mechanical requirements. This enables you to achieve outstanding transparency, gloss, puncture resistance, seal ability and adjustable shrinkage properties.

EVO Multi Bubble: Perfect for you if you…

High-performance films for food packaging

The requirements are particularly high in the food sector. Use EVO Multi Bubble to produce robust and highly transparent shrink packages with barrier function - for example for meat or dairy products. Thanks to its high puncture resistance, you also save material because you can use thinner film. Gain full control over the properties of your polymers and produce flexibly, depending on your application requirements.

Highlights

Producing with EVO Multi Bubble

EVO Multi Bubble

Applications

EVO Multi Bubble:

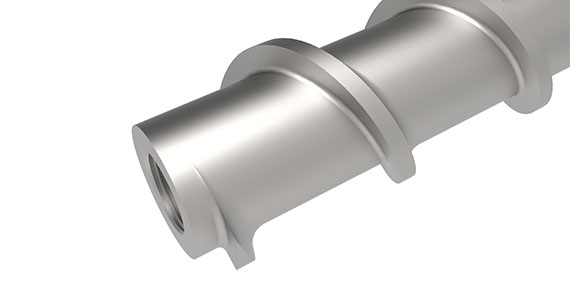

The most important data at a glance

Layflat widths | 25–1100 mm |

Number of layers | 1–11 |

Die diameters | 15–475 mm |

Extruder diameter | 30–80 mm |

ultra features

How to use the full potential of your EVO Multi Bubble blown film line.

Increase performance? Optimize film properties? Reduce manufacturing costs? With our Ultra Features you get the best out of your line.