develop new recipes and processes in-house.

EVO Micro

Laboratory trials and production runs for narrow layflat widths.

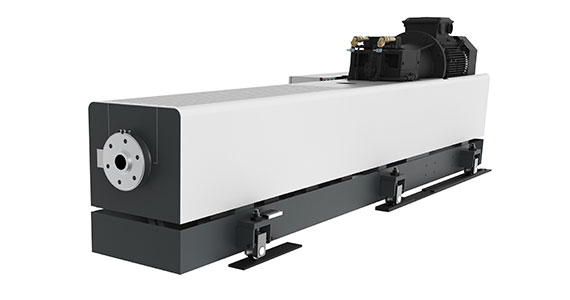

Test under real conditions and efficiently produce small order volumes - both on the same line. With our EVO Micro, you can run economical tests with maximum resource efficiency and results that are 100% transferable to large industrial lines. At the same time, you can also flexibly serve small orders for narrow films that are not profitable on large high-performance systems with complex start-up processes. Profit from short product changes.

EVO Micro: Perfect for you if you

Efficient research and development

Would you like to regularly develop your film recipes or production processes without disrupting your operations? Then invest in an EVO Micro blown film line. Small throughputs, low energy consumption and a small footprint make it the ideal line for research and development. Run your trials with low raw material consumption parallel to the actual production and independent of the R&D capacities of external suppliers. The scalability to large high-performance lines is unique.

Since our EVO Micro lines have the same equipment as our "big" EVOs, they can also be used for the production of narrow layflat widths from 300 - 1000 millimeters. The line is thus ideally suited as a flexible and efficient supplement to large blown film lines.

Highlights

Producing with EVO Micro

EVO Micro

Applications

Good for the environment and margin

Sustainable production with EVO Micro

EVO Micro:

The most important data at a glance

Layflat widths | 300–1000 mm |

Number of layers | 1–9 |

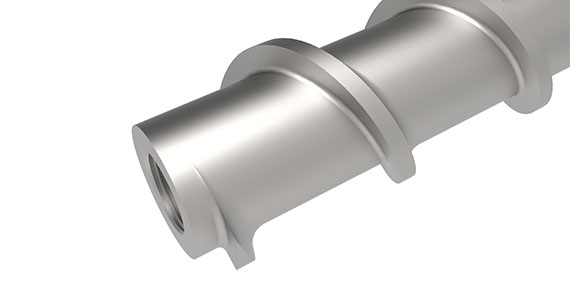

Die diameters | 40–400 mm |

Extruder diameter | 30–80 mm |

Ultra Features

How to use the full potential of your EVO Micro blown film line

Increase performance? Optimize film properties? Reduce manufacturing costs? With our Ultra Features you get the best out of your line.