want to benefit from the growing market for sustainable packaging.

EVO Bio

Compostable film made from renewable raw materials.

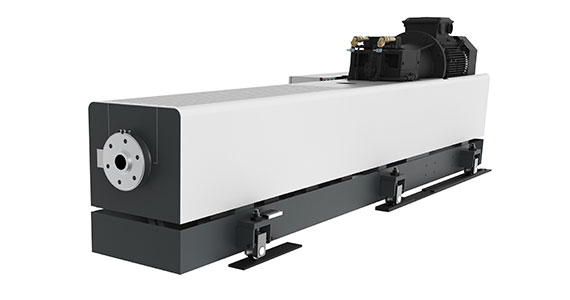

The market for sustainable films is growing steadily. Process biopolymers from renewable raw materials for a wide range of applications - from simple garbage bags to elaborate barrier packaging. A further advantage: after use, they are compostable. With EVO Bio you can easily and flexibly produce sustainable products for future market needs. Our plants are also suitable for the use of conventional raw materials.

EVO Bio: Perfect for you if you

Special applications on flexible lines

Biopolymers and flexibility - they are not mutually exclusive. Our bio lines are based on our standard EVO blown film technology, which we specifically adapt for the processing of biopolymers. Among other things, biopolymers have a lower thermal conductivity, which requires an increased cooling capacity.

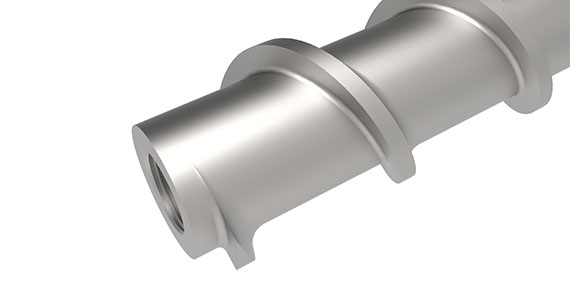

The extrusion section is therefore adapted to the increased material requirements in order to meet the highest performance and quality standards. At the same time, you retain full EVO flexibility and can switch between conventional and biological raw materials depending on market demand.

Highlights

Producing with EVO Bio

EVO Bio

Applications

Good for the environment and margin

Sustainable production with EVO Bio

EVO Bio:

The most important data at a glance

Layflat widths | 1000-3000 mm |

Number of layers | 1–9 |

Die diameters | 120–800 mm |

Extruder diameter | 50–120 mm |

Ultra Features

How to use the full potential of your EVO Bio blown film line

Increase performance? Optimize film properties? Reduce manufacturing costs? With our Ultra Features you get the best out of your line.