attach importance to highest optical film properties.

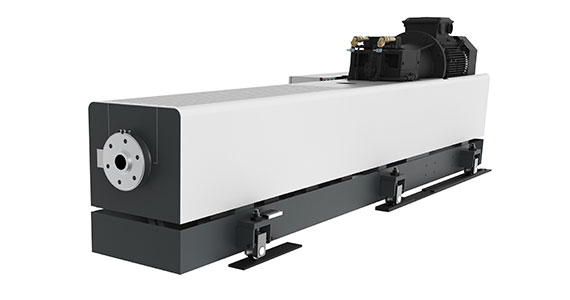

EVO Aqua Cool

Maximum transparency through rapid cooling.

With EVO Aqua Cool you produce highly transparent film thanks to the quick water cooling effect, as the crystallization of the melt is strongly inhibited or even prevented. Further benefits: high gloss, extreme puncture and tear resistance as well as best thermoforming properties.

EVO Aqua Cool: Perfect for you if you

Blown film the other way around

What is the difference between conventional blown film lines and EVO Aqua Cool? Following the force of gravity of water, the extrusion direction is reversed - vertically from top to bottom. The film tube is inflated to the desired diameter and then quickly cooled down by water running down the bubble, thus creating the special optical and mechanical film properties. The water is then removed from the film with the help of negative pressure (vacuum). Our optional Ultra Flat or Ultra Stretch features allow you to optimize stiffness, barrier function or flatness during further processing - without compromising transparency and formability.

Highlights

Producing with EVO Aqua Cool

EVO Aqua Cool

Applications

EVO Aqua Cool:

The most important data at a glance

Layflat widths | 200–1600 mm |

Number of layers | 1-12 |

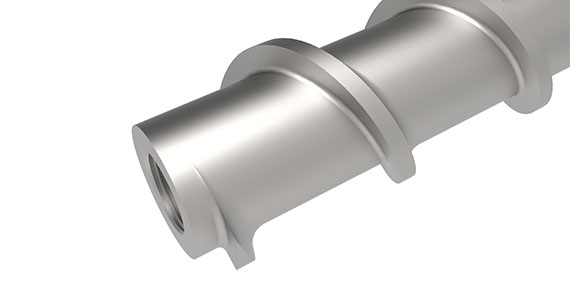

Die diameters | 180 –600 mm |

Extruder diameter | 30–120 mm |

Optionale Features

How to use the full potential of your EVO Aqua Cool blown film line

Increase performance? Optimize film properties? Reduce manufacturing costs? With our Ultra Features you get the best out of your line.