want to react flexibly to different market needs.

EVO

Flexible film production at high quality and cost-efficiency.

Flexible, reliable and future-proof: Our EVO standard lines cover an enormous range of raw materials and applications and can be adapted to special applications at the same time.

EVO: Perfect for you if you

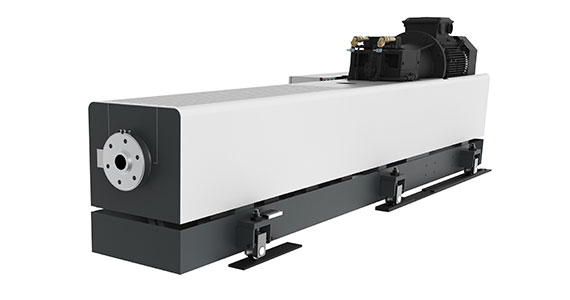

High-tech lines in a modular system

Thanks to the modular system, we adapt each production line to the customer's specific needs. A wide range of extruders, winders, cooling systems, haul-off units etc. is available for this purpose. For products with particularly high quality requirements, choose components from our EVO Ultra series.

Our EVO series is also equipped with state-of-the-art IoT interfaces and can be seamlessly integrated into an "Industry 4.0" production environment. This allows you to automate your processes and have full access to current production data and the condition of your equipment at all times.

Highlights

Producing with EVO

EVO

Applications

EVO compact:

The most important data at a glance

Layflat widths | 1000 - 3300 mm |

Number of layers | 1 - 12 |

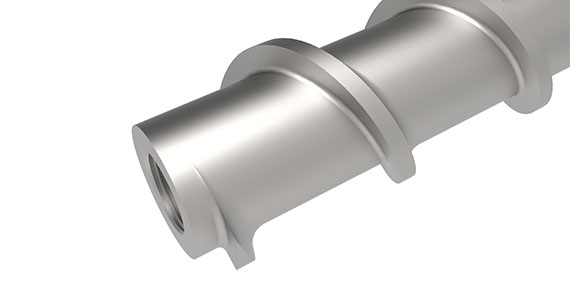

Die diameters | 120 – 800 mm |

Extruder diameter | 50 – 180 mm |

Ultra Features

Ultra Features How to use the full potential of your EVO blown film line

Increase performance? Optimize film properties? Reduce manufacturing costs? With our Ultra Features you get the best out of your line.