1.

Arrange a consultation

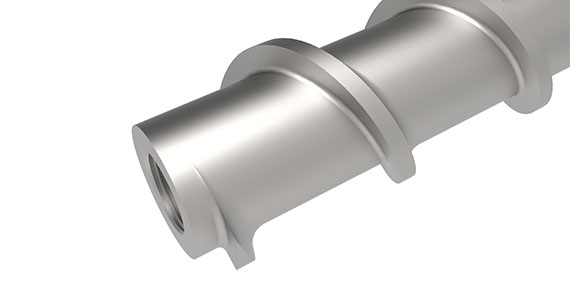

Spinnerets and microcomponents

Spinnerets and microcomponents for machine manufacturers and producers of filaments who demand the highest quality from their product.

High fiber quality requires extreme precision

Are you a mechanical engineering company or a producer of fibers and yarns? Do you expect the highest standards from your products? Are you looking for new solutions? We assist you to produce top quality with our spinnerets for nonwovens, melt spinning, wet and dry spinning, and microcomponents manufactured to high precision.

High-tech spinnerets from Enka Tecnica

Customized Filaments

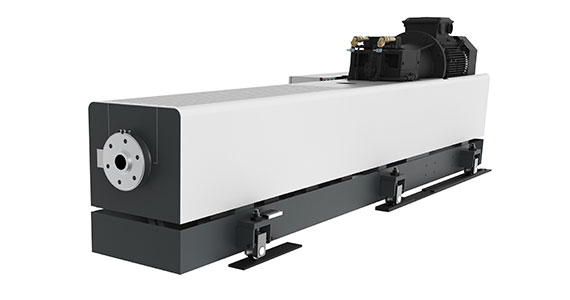

Nonwovens, melt spinning,

wet and dry spinning

Spinnerets

Spinnerets

for nonwovens

Are you looking for something special? Do you want to enhance line performance and have some ideas already? We will implement them.

Spinnerets for

melt-spinning process

Customized, very long-life spinnerets to produce filaments and staple fibers in the melt-spinning process.

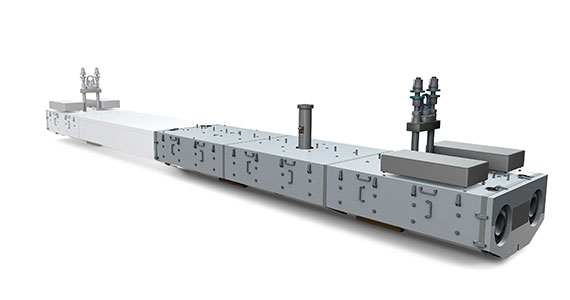

Wet and dry

spinning processes

Spinnerets, supporting devices, and spinning packs to produce high-quality products in wet and dry spinning processes reliably.

SURFACE-FINISHED JET STRIPS FOR HYDROENTANGLEMENT

Jet Strips

Your benefits

Safety through precision

Microcomponents

Portfolio

Technologies

Working with Enka Tecnica