1.

Arrange a consultation

Reifenhäuser Extruders

Expand your business success.

Customized extruders that support your production goals and achieve greater profitability in production.

More successful production with the right extruder

As a producer or machine manufacturer, you probably face the same questions time and again: How can I increase the profitability of my business? How can I develop new markets? How can I meet future requirements without a major new investment? The answer to all these questions could be: with the right extruder. We assist you to find the right extruder for you and show you how Reifenhäuser extruders can increase your business success.

WHAT TO LOOK FORWARD TO

Highlights of your Reifenhäuser extruders

Extruders from Reifenhäuser

Our promise

What would you like to produce?

Choose your extruder

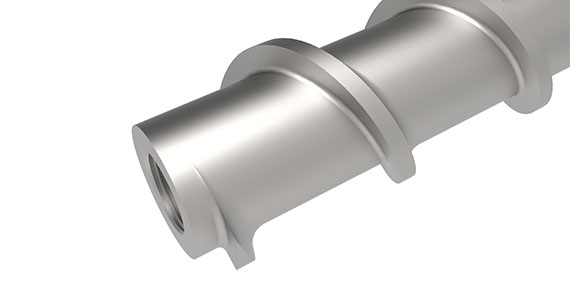

Reifenhäuser single-screw extruders match most product requirements, they are tailor-made and economically efficient. Owing to its wide range of applications and raw materials, this technology can be used with enormous flexibility. To ensure that the extruders match your product requirements perfectly, we design them to meet your requirements. Our extruder construction kit lowers the costs of customization.

- Polyolefins (PE & PP)

- Polyester (PET)

- polyamides (PA)

- Polystyrene (PS)

- Ethylene vinyl alcohol copolymer (EVOH)

- Adhesion promoter (HV)

- Thermoplastic elastomers (TPE)

- Polyvinyl chloride (PVC)

- Thermoplastic terpolymers (ABS)

- Polymethyl methacrylate (PMMA)

- Polycarbonate (PC)+ Circular Economy

- and others

Extruder (Ø) [mm] | 25 – 250 |

Process length [L/D] | 25 – 36 |

Screw type | 3-zone, vacuum or barrier |

Extruder design | Z-design, U-design |

Drive power [kW] | 5 – 600 |

Plasticising capacity [kg/h] | max. 1,500 |

Stop wasting valuable raw materials. The refeeding extruder returns film and nonwoven edge trim directly back to the production process. As opposed to solutions that use mills or regranulation, a refeeding extruder assures high film or nonwoven quality since it eliminates mill dust and thermal stress.

- Polypropylen (PP)

- Polystyrene (PS)

- LDPE

Extruder | Feeding section Ø | Outlet section Ø | Drive | Screw speed | Output PP |

[Type] | [mm] | [mm] | [kW] | [rpm] | [kg/h] |

RS100/50 | 100 | 50 | 25 | 280 | 80 |

RS120/70 | 120 | 70 | 40 | 250 | 120 |

RS140/90 | 140 | 90 | 85 | 210 | 180 |

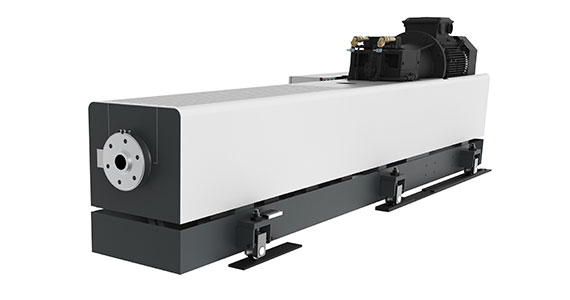

A very high plasticizing capacity is sometimes required when you process PS, PP, or LD-PE. Reifenhäuser high-speed extruders meet this requirement on an extremely small footprint owing to their high screw speed.

- Polypropylene (PP)

- Polystyrene (PS)

- LDPE

Extruder RH034-1-70-36D | Drive | Drive Speed | Plasticizing capacity PP | Plasticising capacity PS | Plasticising capacity LDPE |

[Typ] | [kW] | [U/min] | [kg/h] | [kg/h] | [kg/h] |

HS 1 | 114 | 350 | 100 – 400 | 100 – 450 | 100 – 350 |

HS 2 | 184 | 525 | 100 – 600 | 100 – 700 | 100 – 530 |

HS 3 | 264 | 700 | 100 – 800 | 100 – 950 | 100 – 700 |

HS 4 | 338 | 850 | 100 – 1000 | 100 – 1100 | 100 – 900 |

HS 5 | 378 | 950 | 100 – 1100 | 100 – 1250 | 100 – 1000 |

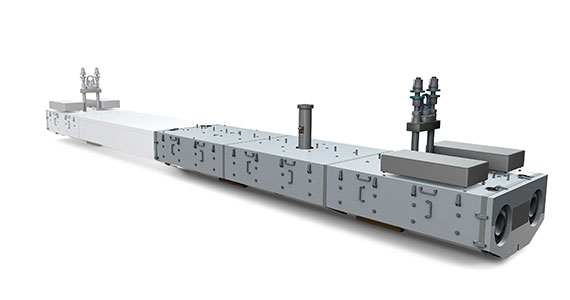

When it comes to compounding and direct extrusion, co-rotating twin screw extruders are unbeatable. Our Reitruder, for example, processes 100% recycled PET material without pre-drying, significantly minimizing energy and raw material costs.

- Polypropylene (PP)

- Polyester (PET)

- Polylactides (PLA)

- Polystyrene (PS)

- Thermoplastic elastomers (TPE)

- Thermoplastic polyolefins (TPO)

- Polymethyl methacrylate (PMMA)

- and others

Diameter ratio of the screws (Da/Di | 1.33 or 1.55 |

L/D ratio | 33 or41 |

Extruder (Ø) [mm] | 43 – 120 |

Drive power [kW] | 40 – 720 |

Throughput [kg/h] | 160 – 2,200 |

Diameter ratio of the screws (Da/Di) | 1.33 oder 1.55 |

More success with Reifenhäuser extruders

How you benefit as a processor

As a producer you are constantly confronted with new requirements. Today, extrusion and injection-molded products must meet high quality standards. They must be inexpensive and sustainable. Save the expense of a new production line and ramp up for the future with a new extruder. Ideal for a quick return on investment.

Optimize resources

How you benefit as a machine manufacturer

Manufacturing inhouse extruders costs you money and valuable time. Outsource the production of these components and save your resources for skills that demonstrate your tur uniqueness. We supply state-of-the-art extruders that match your requirements, add value to your line, and keep your customers satisfied.

Ensure profitability

Service

We help you to achieve long-term production success and support you in expanding your business with existing equipment. We are at your side with support, advice, know-how, and services - in person, by phone, and remotely. Do you know about our services already?