1.

Install Reifenhäuser coextrusion adapter

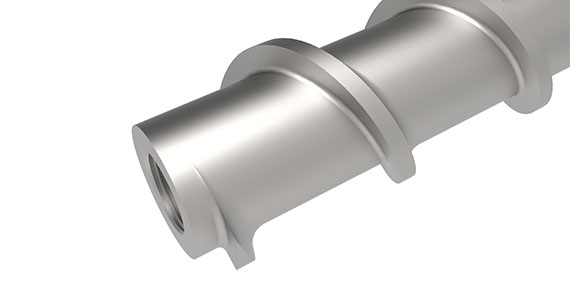

Coextrusion adapters

Producing multilayer composites with minimal tolerances.

Producers often use more raw materials than necessary when manufacturing multilayer films. Avoid this by focusing precisely on layer thicknesses and reduce manufacturing costs.

Work with pinpoint accuracy and increase your margin

Are you one of those producers who lose money because you overlook the importance of single-layer tolerances? Every deviation from the ideal layer thickness unnecessarily increases your manufacturing costs. Reifenhäuser has developed coextrusion adapters to give you precise control over the raw material consumption, avoid waste, and increase profit margins.

Clever features

Highlights of your coextrusion adapters

Coextrusion adapters from Reifenhäuser

Our promise

What do you want to produce?

Select your coextrusion adapters

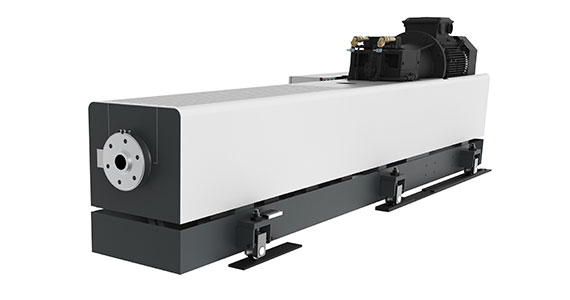

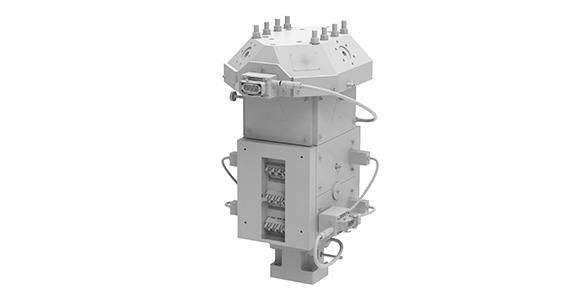

The coextrusion adapter FIX is the right solution for the production of multilayer products made of similar raw materials. High reliability combined with an easy handling characterize this coextrusion feedblock.

| Type | Coextrusion Adapter with a fixed geometry of the flow inserts |

| Number of layers | 2-5 |

| Options | Valve block for closing the covering layers to produce layer structure from A-B-A to A-B, B, B-A. |

| | |

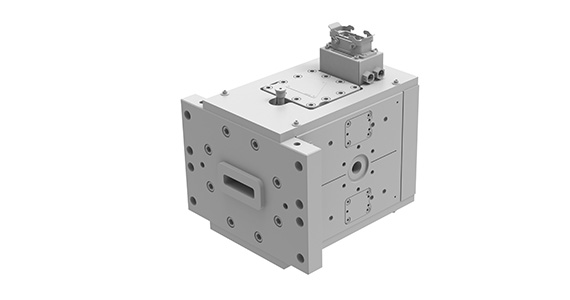

The FLEX Feedblock enables customers to make fast corrections to the flow geometry of all layers (including the middle layer), allowing for an automatic fine-tuning of shear velocity during production. The Flex provides high layer accuracy through an easy profiling system and is also recommended for the use of highly sensitve polymers due to its streamlined flow chanel design. The layer structure can be changed through an integrated channel pack.

| Type | Coextrusion adapter with easy adjustable profilers. |

Number of layers | 2-5 |

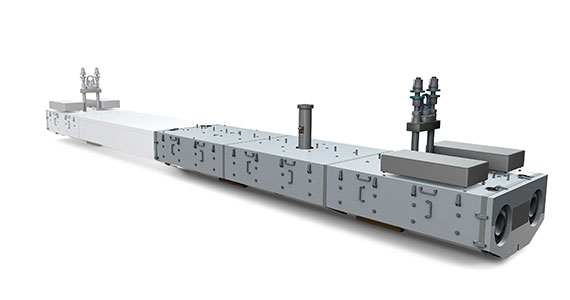

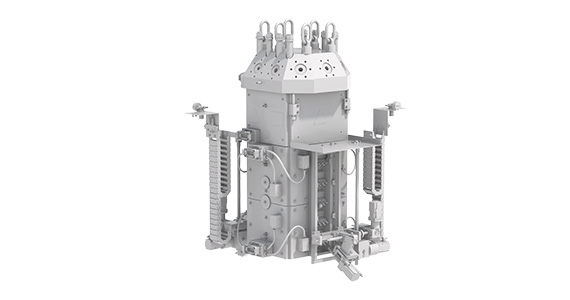

The PRO Feedblock is the best solution for the production of rheologically challenging multilayer structures with high requirements on the quality of the individual layer distribution, e.g. as needed for films and sheets with barrier functions. The patented system with adjustable segmented profilers saves time and valuable raw materials since each layer, including the middle layer, can be adjusted without a stop of the extrusion line. For an easy and fast reproducibility of the individual adjustments, index pins show the exact position of the segmented profilers.

Type | Coextrusion adapter with variable adjustable melt flow channel geometry in the feedblock by segmented profilers |

Number of layers | 3-11 (more on request) |

Options | Internal edge encapsulation for one layer: With this option the normally required additional edge encapsulation extruder as well as the edge encapsulation device of the flat die are no longer needed. This saves space and energy and simplifi es the operation of the entire extrusion line. |

The Coextrusion Adapter PRO is the only Coex System on the market that allows you to profile the individual layers while the line is running. PAM completely automates this adjustment and simplifies adjustments and optimizations through recipe management.

Recipe memory for quick adjustment while the line is running, which increases your good production and makes you less dependent on the qualifications of individual line operators. |

Contactless adjustment while the system is running, which offers operators a higher level of work safety. |

Optimized layer distribution for reduced scrap and material usage, increasing your margin. |

Automatic profiler control for minimal setup and changeover times that improve your efficiency. |

Digital fingerprint for traceability of setting parameters, which makes it easier for you to provide evidence to your customers. |

Produce with greater profitability

How to benefit from Reifenhäuser coextrusion adapters

Ensure profitability

Service

We help you to achieve long-term production success and support you in expanding your business with existing equipment. We are at your side with support, advice, know-how, and services - in person, by phone, and remotely. Do you know about these services already?

Other components from Reifenhäuser

Stop wasting material. Make a precision landing with layer thicknesses and reduce your manufacturing costs.