1.

Contact Reiloy

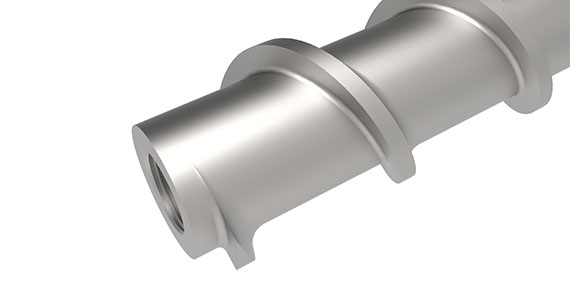

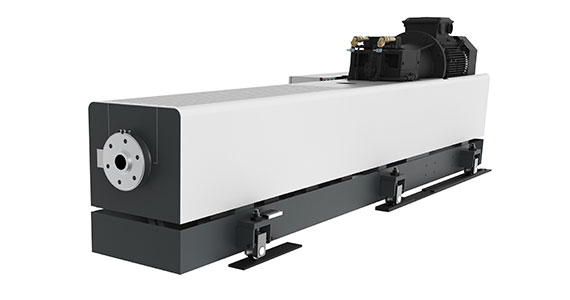

Reiloy barrels

Long service life and quality with top-class wear protection.

Barrels of consistent quality that provide longer protection for your plasticizing units against adhesion, abrasion, and corrosion, even for processing raw materials that cause intensive wear and tear.

Wear protection determines the cost-effectiveness of your plasticizing unit

Do your extrusion or injection-molding lines have lower productivity because your barrels do not match your production percisely or wear out too soon? Reiloy offers you bimetallic barrels with wear protection that match your production requirements exactlyand allow you to continue production for longer.

Something to look forward to

Highlights of your Reiloy barrels

Active for you

We slow down wear

We have over 50 years of experience in manufacturing screws that combine geometry, wear protection, and the right material pairing. Over this time we have assisted countless extrusion and injection-molding machine manufacturers and producers to slow down wear, produce at constant quality, and increase machine availability. We are pleased to advise you and we may even surprise you with an unexpected and interesting price/performance ratio.

Maximum

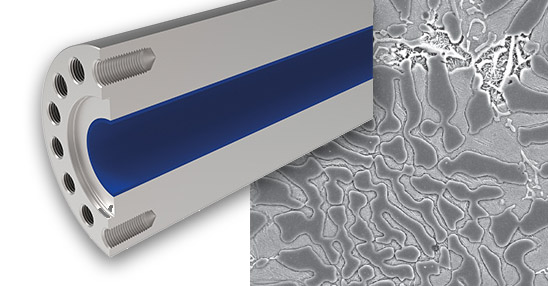

wear protection

Using a specially developed centrifugal process

Outstanding

alloys

Based on inhouse development and production

High-quality

finishing machining

With our state-of-the-art machining centers

Our tip

Only the right questions will result in better wear protection

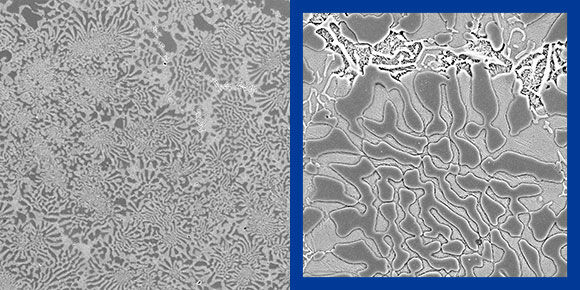

Is hardness really the decisive comparative parameter? How dense are the ceramic phases? How big are the carbides? And When is barrel wear protection really economical? Find the answers right here.

Together with our cooperation partners, we develop wear protection according to the latest technological findings

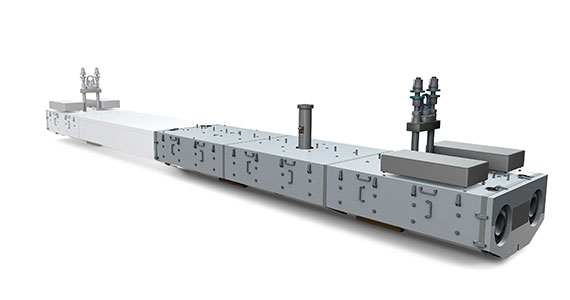

Reiloy bimetallic barrels compact

Key data at a glance

| Design | Blank barrel Semifinished barrel Finished barrel |

| Inside diameter | 14-400 mm |

| Max. outside diameter | 600 mm |

| Max. length | 9000 mm |

From Smart to Premium

Your options

Your requirements for the service life and cost-effectiveness of your plasticizing unit are what determines which barrel is the right one for you. We guide you step by step to the best solution in a consultation.

Smart

Advanced

Premium

What would you like to produce?

Choose the right barrel

For plastics with a filler content up to 30%

Hard metal alloy on iron base. Excellent wear resistance and good corrosive resistance.

ABS, ASA, CA, COC, EVA, HDPE, HIPS, LDPE, PA, PBT, PC, PEEK, PEI, PESU, PET, PF, PMMA, POM, PP, PPA, PPS, PPSU, PS, PS transparent, PSU, PVC-C, PVC-P, PVC-U, PVDF, SAN, SB, TPE, TPU

Alloys

| Injection Molding | Reiloy standard R121 |

| Extrusion | C60 (1.0601) R1 |

For plastics with a filler content up to 40%

Hard metal alloy on iron base with added vanadium. Very high wear and corrosive resistance with enhanced ductility.

ABS, ASA, EVA, HDPE, HIPS, LDPE, PA, PBT, PEEK, PEI, PESU, PET, POM, PP, PPA, PPS, PPSU, PSU, PVC-C, PVC-P, PVC-U, TPE, TPU

Alloys

| Injection Molding | Reiloy Standard R131 |

| Extrusion | Reiloy Standard R131 |

For plastics with a filler content greater than 40%

Two-phase hard metal alloy on nickel base with tungsten carbides. Maximum wear and corrosive resistance.

ABS, ASA, EVA, HDPE, HIPS, LDPE, PA, PBT, PEEK, PEI, PESU, PET, POM, PP, PPA, PPS, PPSU, PSU, PVC-C, PVC-P, PVC-U, TPE, TPU

Alloys

| Injection Molding | Reiloy Standard R241 |

| Extrusion | Reiloy Standard R241 |

For special applications

We offer special alloys for the production of complex products, such as PRFE, PFA, FEP.

Find the right alloy for your raw material here and compare service life and economy.

Increase productive times

Save costs with excellent alloys

The wide range of alloys on the market can be confusing. Our experts guide you through the options and cooperate with you to find out the best armor alloy for your production with bimetallic barrels.

Smart

R121

Excellent wear resistance with good corrosion resistance

| Wear resistance | +++ | |

| Corrosion resistance | +++ | |

| Layer thickness | 1.5 mm | |

| Roughness Ra | min. 0.2 – max. 0.8 | |

| Inner diameter | 14 – 400 mm | |

| Outside diameter | max. 600 mm | |

| Length | max. 9,000 mm | |

| Hardness at room temperature | min. 65 HRC | |

| Main alloy component | Cr, Ni, Mo, B | |

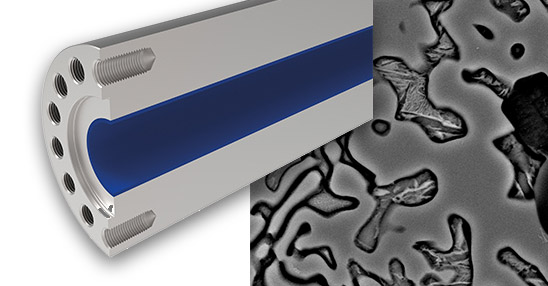

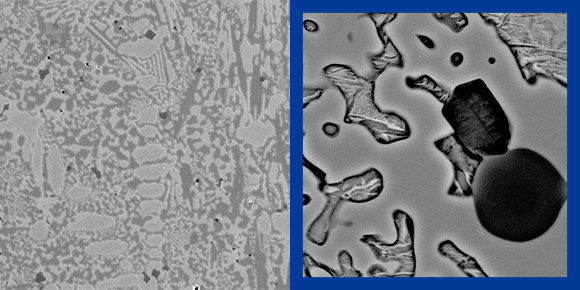

| Structural description | Martensitic iron-based alloy with primarily solidified chrome carbides and Carbo-Boride Phases |

Advanced

R131

Very high wear and corrosion protection, with improved ductility

| Wear resistance | ++++ | |

| Corrosion resistance | ++++ | |

| Layer thickness | 1.5 mm | |

| Roughness Ra | min. 0.2 – max. 0.8 | |

| Inner diameter | 14 – 90 mm | |

| Outside diameter | max. 230 mm | |

| Length | max. 3,000 mm | |

| Hardness at room temperature | min. 60 – 64 HRC | |

| Main alloy component | Fe, Cr, V, B, Ni | |

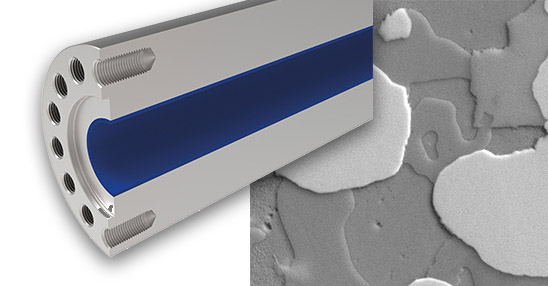

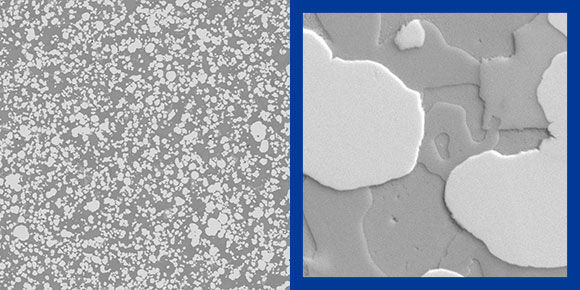

| Structural description | Martensitic iron-based alloy reinforced with vanadium carbides and Carbo-boride phases |

Premium

R241

Maximum wear and corrosion protection

| Wear resistance | +++++ | |

| Corrosion Resistance | +++++ | |

| Layer thickness | min. 1.0 mm | |

| Roughness Ra | min. 0.3 – max. 0.8 | |

| Inner diameter | 15 – 300 mm | |

| Outside diameter | max. 600 mm | |

| Length | max. 9,000 mm | |

| Hardness at room temperature | min. 59 HRC | |

| Main alloy component | W, Cr, B | |

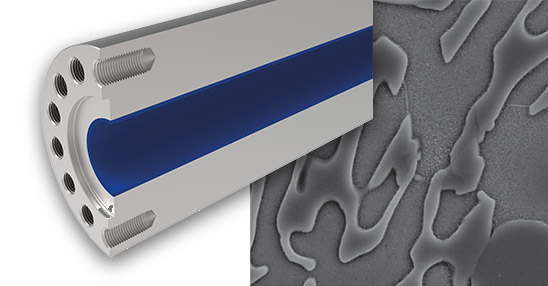

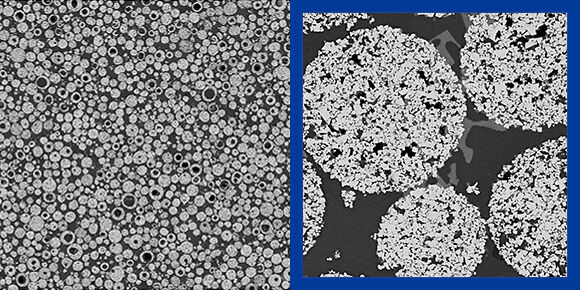

| Structural description | Dispersive hardening of a highly corrosive resistant Ni-matrix alloy with thermally stable tungsten carbides |

Select

R115

Maximum resistance to corrosive stress

| Wear resistance | + | |

| Corrosion Resistance | +++++ | |

| Layer thickness | min. 1.5 mm | |

| Roughness Ra | min. 0.2 – max. 0.8 | |

| Inner diameter | 15 – 105 mm | |

| Outside diameter | max. 350 mm | |

| Length | max. 3,000 mm | |

| Hardness at room temperature | min. 55 HRC, Di > 60 mm min. 47 HRC | |

| Main alloy component | Co, Cr, B | |

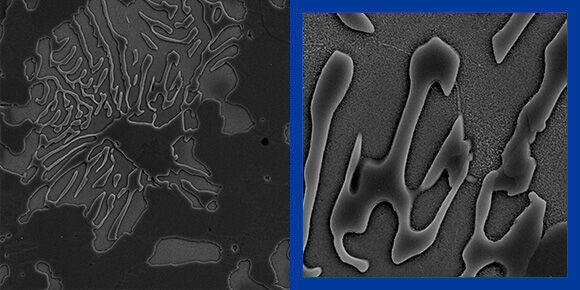

| Structural description | Nickel-cobalt base alloy with fine precipitation of primary solidified nickel borides and eutectically solidified chromium carbides |

Advanced

R239

High wear protection with maximum corrosion resistance

| Wear resistance | ++++ | |

| Corrosion Resistance | +++++ | |

| Layer thickness | min. 1.0 mm | |

| Roughness Ra | min. 0.2 – max. 0.8 | |

| Inner diameter | 18 – 165 mm | |

| Outside diameter | max. 290 mm | |

| Length | max. 3,000 mm | |

| Hardness at room temperature | min. 58 HRC | |

| Main alloy component | W, Cr, B | |

| Structural description | Dispersive hardening of a highly corrosive resistant Ni-matrix alloy with common tungsten carbides |

Our promise