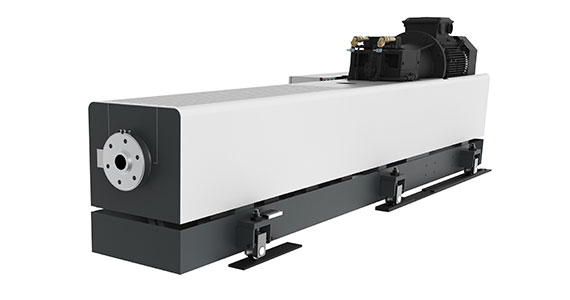

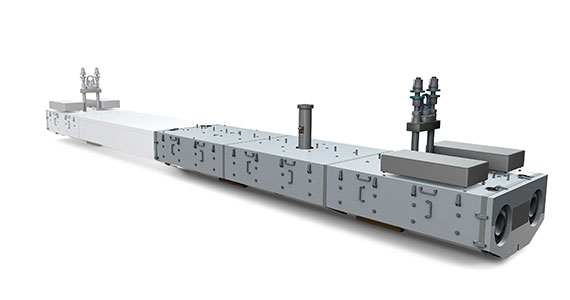

Coextrusion adapters, extruders, dies

Reifenhäuser

Extrusion Systems

Components

Tailor-made components for extrusion and injection molding

Tailor-made components for extrusion and injection molding

Reifenhäuser Extrusion Systems

Reifenhäuser Extrusion Systems develops and manufactures tailor-made melt-guiding and forming components for extrusion and injection molding at the price of standard solutions. We help you to produce top-class quality efficiently and economically. If the specifications are still open apart from an end-product requirement, we will guide you step by step to the ideal component, or manufacture a component for you based on to a specific drawing. The Business Unit Extrusion Systems (coextrusion adapters, flat die heads) is a merger of the companies Reiloy (screws and barrels), Enka Tecnica (spinnerets, microcomponents, and meltblown spinning beams), and the former company of Reifenhäuser Extrusion (extruders).

Coextrusion feedblocks, extruders, dies

Reifenhäuser Extrusion Systems

As a customer, you benefit from over 40 years of experience from our own processes and manufacturing methods, a direct exchange between engineers, and a field-proven modular system.

Spinnerets, meltblown spinning beams, and microcomponents

Reifenhäuser Enka Tecnica

Whether the products are cleaning cloths, cotton-wool fleece, cigarette filters, carpets, sterile disposable clothing, dialysis filters, high-strength fabrics, carbon fiber composites, car tires, insulation, filters, or clothing for six billion people – the modern world of today is unthinkable without man-made fibers – or without spinnerets. We know from experience that these dies and high-end microcomponents depend on one highly important thing: maximum precision. That's why we manufacture the perfect hole for you with unparalleled precision, so that you can reliably achieve the highest product quality.

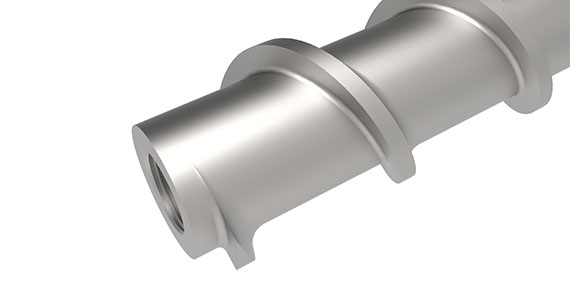

Highly wear-resistant screws and barrels

Reifenhäuser Reiloy

Lines are only as reliable as the wear protection on their plasticizing unit. Therefore, Reifenhäuser Reiloy manufactures and processes high wear-resistant barrels and screws for extrusion and injection molding processes that match your requirements so that you can exploit their full potential in terms of product quality and line availability. Using our hard alloys and processes produced inhouse , we achieve proven top-class wear protection that reliably protects your components against abrasion, adhesion, and corrosion. We promise you consistent Reiloy quality with no fluctuation. With more than 40 years of experience, our metal know-how, and our know-how from research and development, we can also advise you on all questions relating to wear protection.

To the products

News & Stories

Reifenhäuser Extrusion Systems latest News

Get to know the whole group