Fitesa reduces the carbon footprint with an energy concept from Reifenhäuser Reicofil

Fitesa, one of the leading manufacturers of nonwovens, produces high-quality nonwovens for hygiene and healthcare products on Reicofil Lines across the globe. The newest line at its Norrköping site (Sweden) has been delivered with BLUE EXTRUSION insulation for increased energy efficiency. Reifenhäuser Reicofil not only insulated the line components, but also developed and implemented a comprehensive energy-saving concept for the production facility.

Fitesa reduces the carbon footprint of its nonwoven production

Fitesa has a target of reducing the company’s energy consumption and CO2 emissions by 10% until 2025 (actual results per tonne of product versus 2017). One of the initiatives taken in this direction was a review of the energy footprint at its Norrköping plant. Anders Fogelberg, Global Safety, Quality, HSE and Management System Global Director at Fitesa says: "Our objective was to improve the energy profile and significantly reduce the carbon footprint. We are systematically pursuing this approach at all our sites."

FITESA

Fitesa is one of the world’s largest spunmelt nonwovens manufacturers. The company specializes in the development of innovative solutions for the hygiene and healthcare markets by utilizing a broad range of technologies, including spunbond, spunmelt, meltblown, carded, airlaid, spunlace, films and elastics. Headquartered in Porto Alegre, Brazil, Fitesa employs over 2,600 people in 23 manufacturing locations across 13 countries.

The special feature in Norrköping is its location on the 58th parallel – this makes it the northernmost production site within the global corporation. Here, in a climate zone with moderately warm summers and low temperatures in winter, it is essential to heat the production hall. Since a lot of heat is generated in the production of nonwovens, it seemed the obvious solution was to use the waste heat from the composite line for this purpose. "Of course, we discussed this with our contacts at Reifenhäuser, who sat down with us at the planning table and developed a comprehensive energy concept," Fogelberg tells us, adding: "This allowed us to dispense with an additional heating system in the production facility that would otherwise have been necessary."

Three steps to energy efficiency

The first and simplest method to save energy is to insulate line components. Insulation can also be retrofitted very simply on existing Reicofil lines.

A far more complex and highly customized task is to develop an overall energy concept to reduce the carbon footprint in production, based on environmental conditions, available energy sources - such as fossil gas or electricity from renewable energy sources - and the air-conditioning systems in the production hall, as Sales Manager Falk Roesner explains

After analyzing these parameters, Reifenhäuser Reicofil put together a BLUE EXTRUSION package for Fitesa consisting of three measures: Enhanced insulation for line components, a customized heat recovery system for the plant, and an analysis of the energy-saving potential at other Fitesa sites.

Reifenhäuser Reicofil: Specialist for nonwoven lines and sustainability partner

Reifenhäuser Reicofil is a specialist and leading global manufacturer of complete spunbond, meltblown, and composite lines supplying lines that allow customer products to meet the highest quality standards in hygiene, medicine and filtration. In addition, Reifenhäuser Reicofil advises and supports its customers on their path to energy-efficient, CO2-neutral production, and identifies energy-saving potential.

Enhanced insulation for extruders, calenders, and dryers

At the Fitesa plant in Norrköping, the aim was to prevent heat escaping from the plant to the environment and to retain it within the system. To achieve this, a new Reicofil line was clad in a kind of insulation suit, a non-combustible, blue, insulating material that is heat-resistant up to 500°C. In principle, all heat-bearing components on the lines can be encased, such as extruders, calenders and dryers.

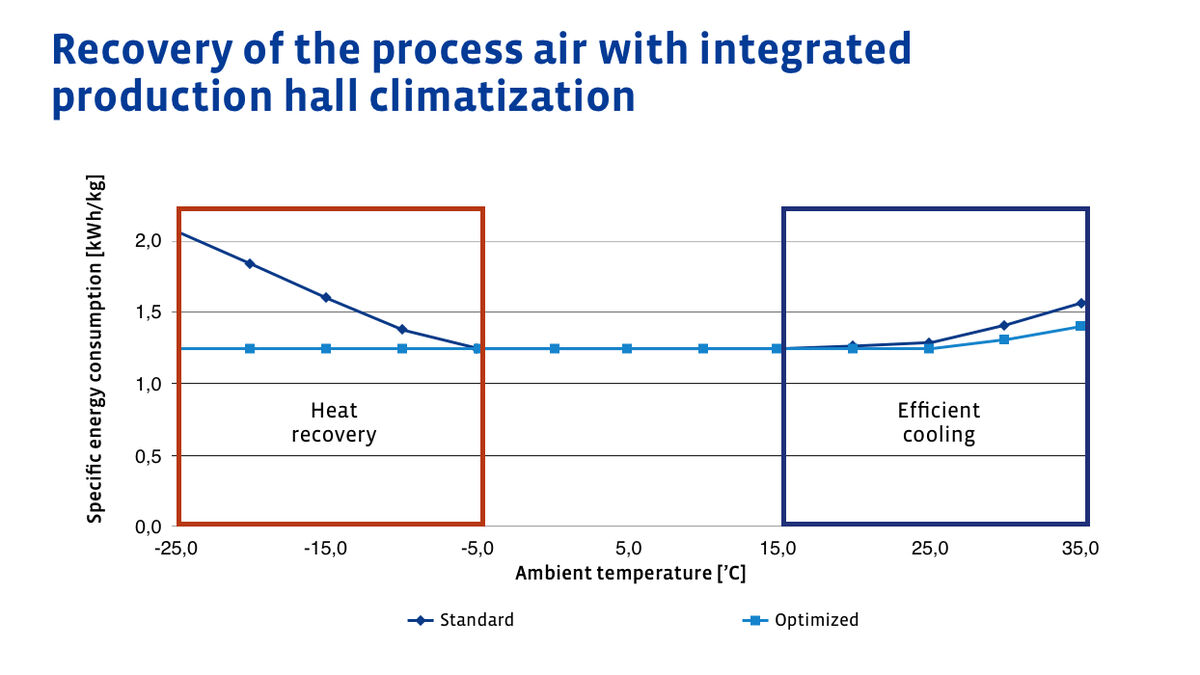

Heat Recovery

Of course, heat recovery for heating purposes is only relevant in regions where it is so cold that the hall needs to be heated, at least temporarily. However, the system here must function in both directions, i.e., it must also dissipate heat to the outside when needed. And for sites in warmer climates, it might make sense to focus on alternative cooling concepts instead. Falk Roesner, Sales Manager at Reifenhäuser Reicofil summarizes: "So, it's not enough to just look at the machines. We must take an overall view of the line, the building, and the site in order to produce a reasonable energy concept."

BLUE EXTRUSION

- Use of climate-friendly energy to control line temperature

- Insulation of line components

- Energy concept taking into account mass and energy balance

At the Fitesa plant in Sweden, for example, Reicofil installed heat exchangers to extract heat from the waste air and feed it to the building's heating system. "Here, too, the crucial question is: What are the points where this is viable?” cautions Roesner. “In theory, we could fit a heat exchanger in every air stream. On the downside, however, every measure must be worthwhile both economically and ecologically. Because in the end, the more materials we use, the higher the CO2 consumption, and this in turn must be compensated. This calculation is also part of Reifenhäuser's consultancy services."

Fitesa site has the lowest energy consumptionIn Roesner's estimation, the investment costs for this project should amortize in about five years. "The easiest efficiency yardstick is the electricity bill," he says. This means: Rising energy prices accelerate the return on investment. |

Fitesa director Fogelberg regards a reduction in carbon footprint as at least as important as ROI when evaluating the BLUE EXTRUSION package: "Of course, it saves us money. But energy efficiency is the moral obligation, not necessarily the economic objective. We simply can't afford to be wasteful anymore. That's why we're taking responsibility," he emphasizes. |

The Reifenhäuser Reicofil energy concept has proven its worth: Fogelberg says the Norrköping plant has the lowest energy consumption per tonne of material produced of all Fitesa sites, despite the cold Swedish winter.