Successful growth thanks to quality

The rapid development of GreenPak started in 2013: Reifenhäuser's first blown film line went into operation in Jiangyin (China). Hu Gang as owner and Colin Wang as Managing Director had set themselves the goal of producing outstanding film quality and exporting it worldwide.

Only ten years later, GreenPak produces flexible packaging solutions on four Reifenhäuser blown film lines, primarily for the food industry, and supplies customers in the USA, Canada, the EU, Russia, South America, Asia and other countries around the world.

GreenPak

- Founded in 2011

- Headquarters: Jiangyin

- Employees: 150

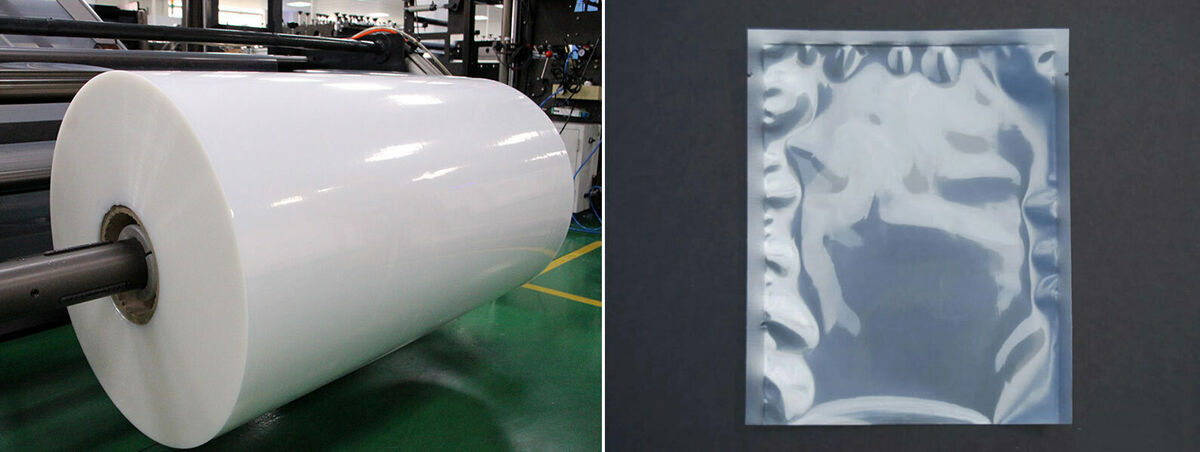

- Film products for food, such as vacuum pouches, embossed vacuum pouches, vacuum sealer rolls, forming films, lidding film, stand-up pouches, printed bags, lamination film, VFFS and HFFS material.

- Markets: flexible packaging solutions for the food industry and others Industrien

From the roll to the bag: GreenPak has the quality completely in its own hands

GreenPak grows thanks to Reifenhäuser quality

Even though the company has developed rapidly, Hu Gang and Colin Wang have always followed a policy of cautious, natural growth. "We only invested in new lines when the markets were prepared and we could ensure that we reliably met our customers' quality requirements," Wang reports. Reifenhäuser's "Made in Germany" lines play a decisive role in this - or as GreenPak puts it on the company website "Perfect products produced by German lines".

Blown film lines from Reifenhäuser enable GreenPak, for example, to achieve minimal profile tolerances, very good optical film properties and a low curling tendency with asymmetrical films. "Beyond consistent film quality, our technology ensures high line availability so that GreenPak can supply its customers on time," says Eberhard Wenger, Senior Application Manager at Reifenhäuser Blown Film.

Quality Promise Blown Film Lines

- Expert support

- Customized solutions

- Competent and comprehensive advice

- Application and process know-how

- Sustainable production

- Outstanding cost-effectiveness

- Innovative applications

Learn more about blown film lines from Reifenhäuser

Plant and machinery expanded step by step

The first line, a 7-layer blown film line, was followed in 2016 by a 9-layer barrier line from Reifenhäuser. Already a short time later, Greenpak dealt with an expansion of production. New halls had to be built. Packing was also to grow and logistics were to be improved. In December 2020, in the middle of the Corona pandemic, the time had come: GreenPak had increased sales so much that another extrusion line could be utilized to capacity - and ordered two new 9-layer extrusion lines from Reifenhäuser at once. These went into operation in April 2022 and October 2022.

Eberhard Wenger, Sales Manager from Reifenhäuser (left) and Hu Gang, owner of GreenPak in front of a Reifenhäuser EVO Blownfilm Line

Relationship based on partnership

With the help of the two latest lines, GreenPak has developed into one of the largest manufacturers of barrier films in China - always closely accompanied by the Reifenhäuser team around Eberhard Wenger. "Over the years, we have developed a friendly relationship based on partnership, with objective professionalism for our joint business." And Colin Wang confirms: "We appreciate the trusting relationship we have built up."

It was a relationship of trust that continued to grow despite travel restrictions during the Corona pandemic. "In 2022, it was not possible for us to commission the lines on site with personnel from Germany," Wenger relates. "But due to the customer's experience with our lines and the support of Reifenhäuser's Chinese colleagues and remote commissioning team, both new lines were commissioned in a fairly short time."

Both new lines have been running continuously since then and, like the two older lines, are fully utilized. By the end of 2025, GreenPak is aiming for an output of 20,000 tons per year - and is constantly developing its own portfolio. This is certainly not the end of the successful growth story at GreenPak.