Understanding meltblown

Key facts about the filter material and how it makes medical products safe.

Face masks and medical protective clothing are made of non-woven fabric. The so-called meltblown, which acts as a filter, gives the products their actual function: a high separation efficiency against the smallest particles, such as bacteria and viruses.

Understanding meltblown

An overview of the most important questions

What is meltblown?

Meltblown is a nonwoven fabric made of extremely fine, melt-spun microfibres. The fibers are up to seventy times thinner than a human hair and one fiber sometimes has an average thickness of only one micron. The raw materials used for meltblown spunbonds are polymers, e.g. polypropylene is generally used for face masks.

How do filters work?

Good filters work like doormen: They only let through what is wanted. This task becomes all the more complex, the smaller the particle size is which needs to be filtered. A simple sieve effect, as known from sandboxes, is no longer effective to handle very small particles, such as viruses and bacteria. In the case of face masks, for example, an additional combination of effects such as inertial impaction, diffusion, and electrostatic attraction are active at the same time.

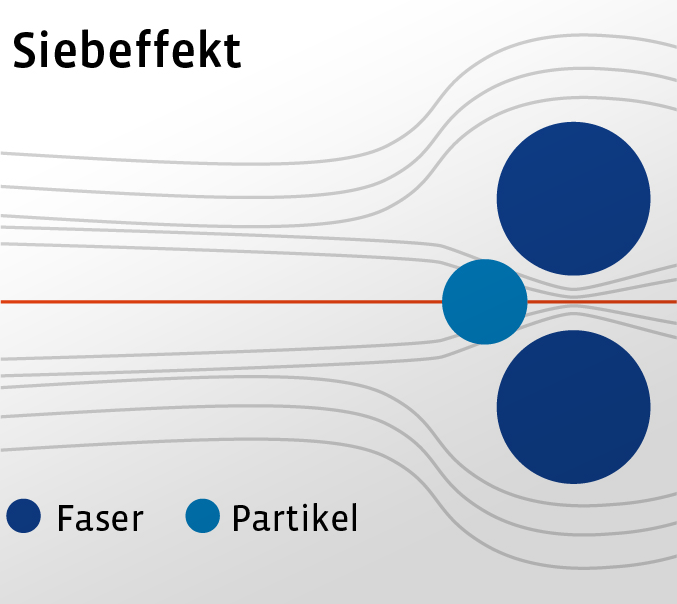

Sieve effect: Particles larger than a specific size are entrapped in the meshes.

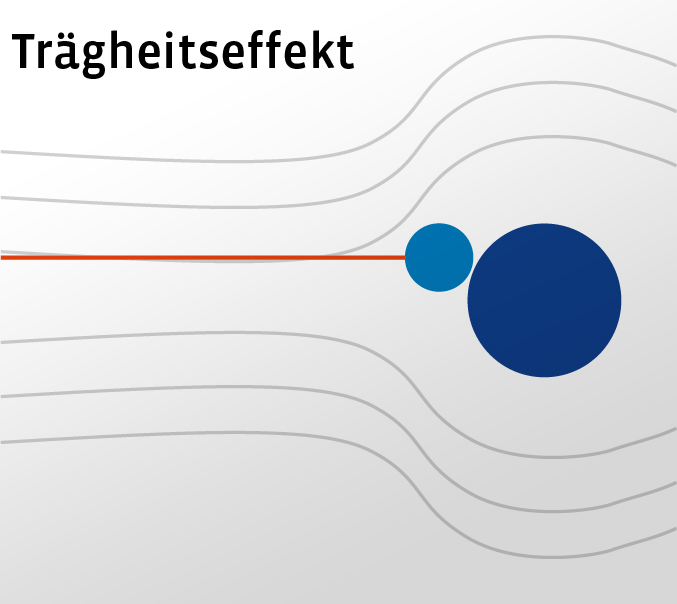

Inertia effect: Larger particles are unable to move in the air flow round the filter fibers. They maintain their direction, hit the fibre and stick there.

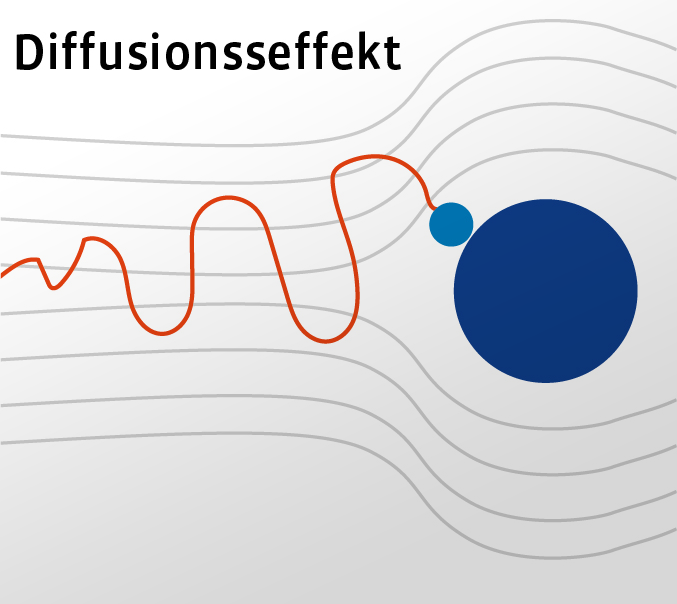

Diffusion effect: Very small particles, such as viruses, often move along irregular paths in the air flow. This results in a high possibility probability of contact with filter fibers.

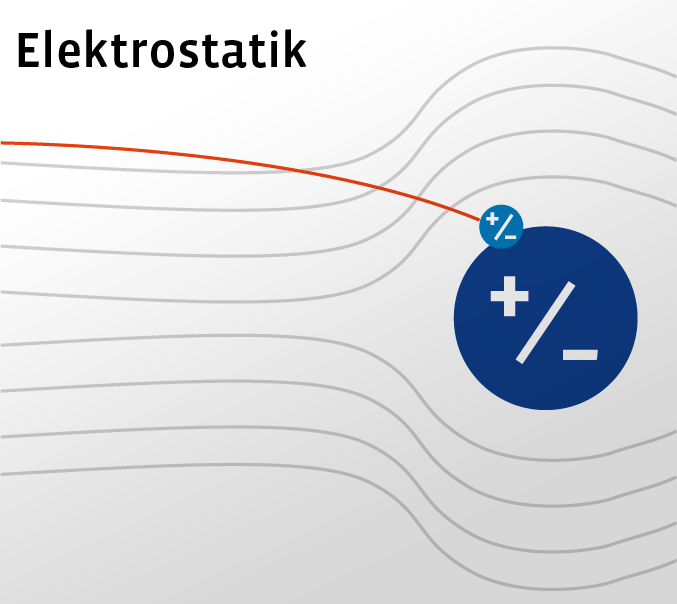

Electrostaticattraction: To enhance diffusion and inertia effect, materials are electrostatically charged in order to filter minute particles. The filter fibers then attract particles like a magnet and entrap them.

What makes a good filter?

- High filtrationefficiency: As many particles as possible are entrapped in the filter.

- Low pressure drop: It is easy to breathe through the filter.

- High absorption capacity: As many particles as possible can be absorbed before the filter becomes clogged and pressure drop increases. Moisture in the breath reduces filter capacity. This is why filters must be replaced at regular intervals.

- Low cost: Filters are often the functional layer of a disposable product, as is the case with medical applications.

Why is meltblown an ideal filter material?

- Meltblown nonwovens consist of extremely fine fibers that are on average 1 µm thick and of endless length. By comparison, a cotton fiber is 12-35 µm thick and 15-56 mm long

- Meltblown nonwovens are produced in different thicknesses and densities. Example: A 25 g/m meltblown nonwoven consists of max. 500 fiber layers.

- Due to its structure and its additional electrostatic charge, all the filter effects act simultaneously in a meltblown nonwoven. Even the minutest particles, which may contain the coronavirus, are entrapped reliably.

- Filters made from meltblown combine high performance with good wearing comfort (easy to breathe) since a proper balance between filtration efficiency, absorbtionstorage capacity, and pressure drop can be realized. Moisture in the breath reduces filter capacity. This is why filters must be replaced at regular intervals.

- The material is low-cost and can be produced rapidly in large quantities.

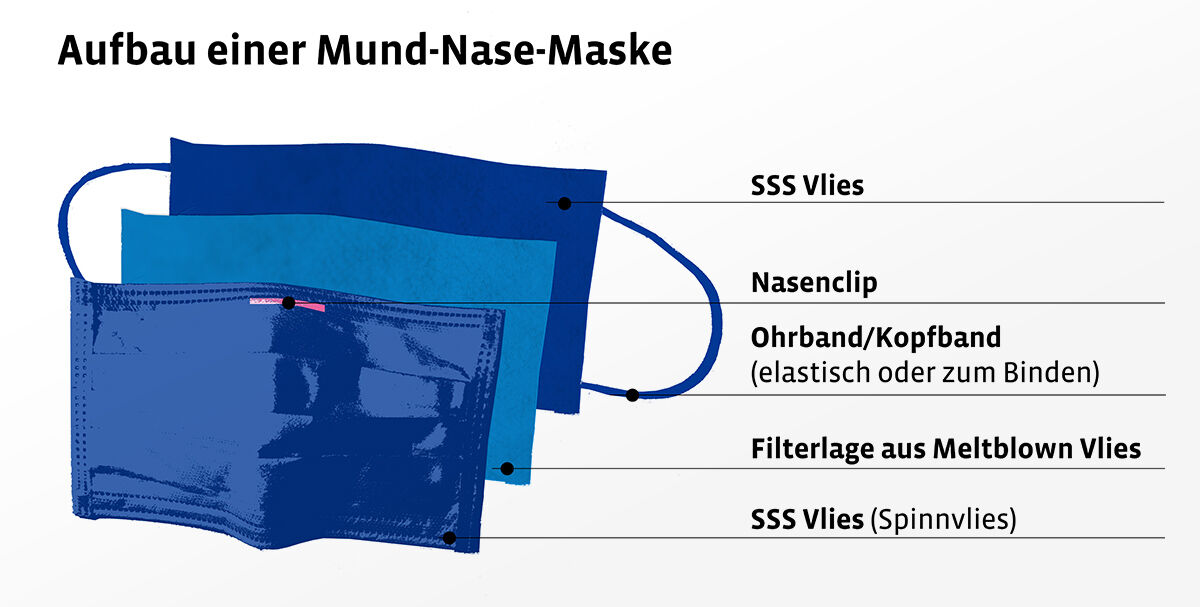

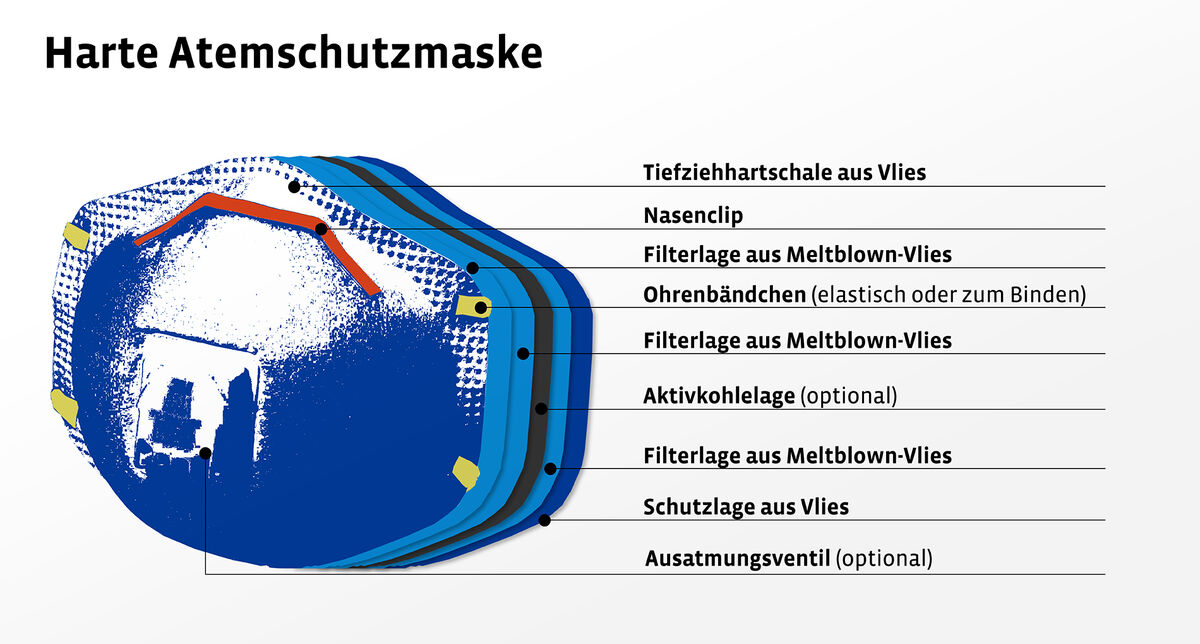

How are mouth-nose masks and respirators constructed?

There are many different medical face masks. But basically they are divided into two skin categories, the structure of which is quite different. What all masks have in common: The filtering layer made of meltblown, which is made in different layers and basis weights, depending on the application:

1. mouth-nose masks

Standard EN 14683 Type I, II, IIR

Mouth-nose masks or so-called surgical masks primarily protect the environment from the wearer.

2. respirators

Standard EN 149 FFP 1-3

Respirators protect the wearer from infection. These masks are required by personnel who come into contact with people who are already infected. Only if the respirator does not have an exhalation valve, it also provides protection in the other direction.

What meltblown qualities are required for face masks?

All medical face masks are equipped with so called N95* and N99* meltblown nonwovens, whether they are face masks or respirator masks. Nevertheless, the nonwovens differ considerably from one another since the specifications are always linked to the size of the particles filtered. An N95 meltblown to filter building dust requires a different production process than an N95 meltblown to filter viruses.

Therefore, when ordering meltblown material, the filter performance required must be specified exactly as well as the intended purpose of the filter. It is not enough to specify simply N95 nonwoven or N99 nonwoven.

* The values N95 and N99 indicate the percentage of a specified particle size range absorbed by the material.