1.

Arrange a consultation

RF5 Composite

Meet quality standards in hygiene and medicine reliably.

Produce top-class composite nonwovens with high strength and barrier properties that make you a sought-after supplier of top quality.

Demanding markets require consistent nonwoven quality

Average or fluctuating nonwoven grades are a risk and therefore taboo for applications that are supposed to provide protection and safety. RF5 composite lines consistently produce the same high quality, making you a reliable supplier that gives customers the peace of mind they need.

Clever Features

Highlights of RF5 composite lines

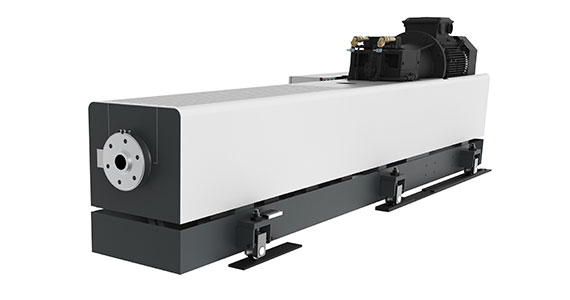

RF5 Composite line compact

The most important data at a glance

| Configurations | SMS to SSMMMMSS |

| Line widths | 1000, 1600, 2400, 3200, 4200, 4400, 5200, 5400 |

| Max. Speed on conveyor belt | 1200 m/min |

| Max. Speed on winder | 1400 m/min |

| Max. specific throughput for SB | 270 kg/h/m |

| Max. specific throughput for MB | 70 kg/h/m |

| Basis weight | 8 - 70 g/m² |

| Titer-Range for normal PP | 1,2 - 1,8 den (higher on request) |

| Titer-Range for Metallocene | 0.9 - 1.1 den |

| Raw materials | |

| PP, PE | inclusive |

| PET/PLA/others | optional |

| Technologies | |

| Bico | optional |

| Semi High Loft and High Loft | optional |

| Full High Loft | optional |

Optional features

How to use the full potential of your

RF5 composite line

More features or extra convenience? Choose from optional technologies and packages to customize the line for specific needs.

Anti-contamination

The purest nonwoven you have ever produced

- Housing of the spunbond and meltblown system

- Cover above the wire belt

- Protection for downstream equipment

Efficiency

More time for really important things

- Automatic press roll cleaner

- Automatic belt cleaner

- Automatic die inspection system

Energy

Less waste of resources and money

- Energy packages for calenders, winders, dryers

- Energy efficient motors

- Heating with gas

- Heat recovery

- Energy monitor

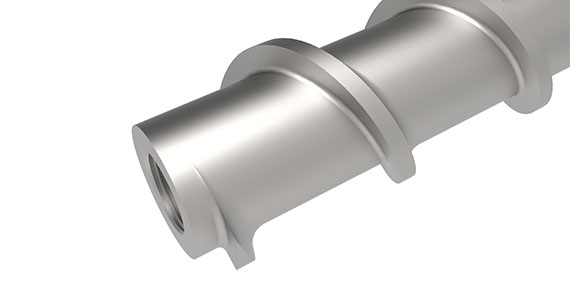

BiCo

For the combination of two raw materials in one fiber

The BiCo spunbond process combines two different raw materials in one fiber, opening the door to product properties that are unattainable with monofibers - for example, the combination of superior strength and formability.

Digitization

For smarter production

Your plant is constantly producing valuable data. Don't let this potential lie dormant any longer. Our digital features help you produce more conveniently, more profitably and more intelligently.

- Machine control

- DRS Dashboard

- DRS System base module

Full High Loft

For soft nonwovens with maximum thickness

With Reicofil Full High Loft technology, you produce optically absolutely uniform nonwovens that can compete with the fur of the cuddliest teddy in terms of softness and thickness. Ideal for hygiene (e.g. topsheet, backsheet) and filtration (e.g. pre-filters and depth filters).

Semi High Loft / High Loft

For soft and voluminous nonwovens

With Reicofil Semi High Loft and High Loft technology, you make products that combine stability with a soft surface. Ideal for applications in hygiene (e.g. topsheet, backsheet, leg cuff, cuffs).

Ensure profitability

Reicofil Service

We help you achieve long-term production success and support you in expanding your business with existing equipment. We are at your side with support, advice, know-how and services - in person, by phone and remotely. Do you already know the following services available from us?