1.

Arrange a consultation

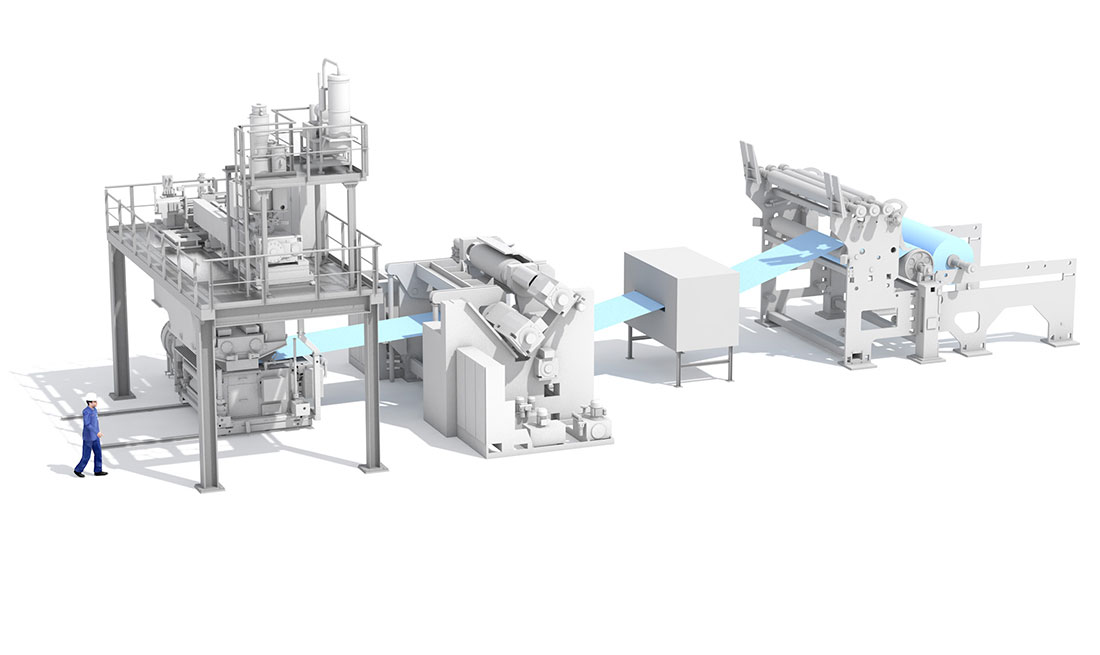

RF Meltblown

Produce filter material that converters trust

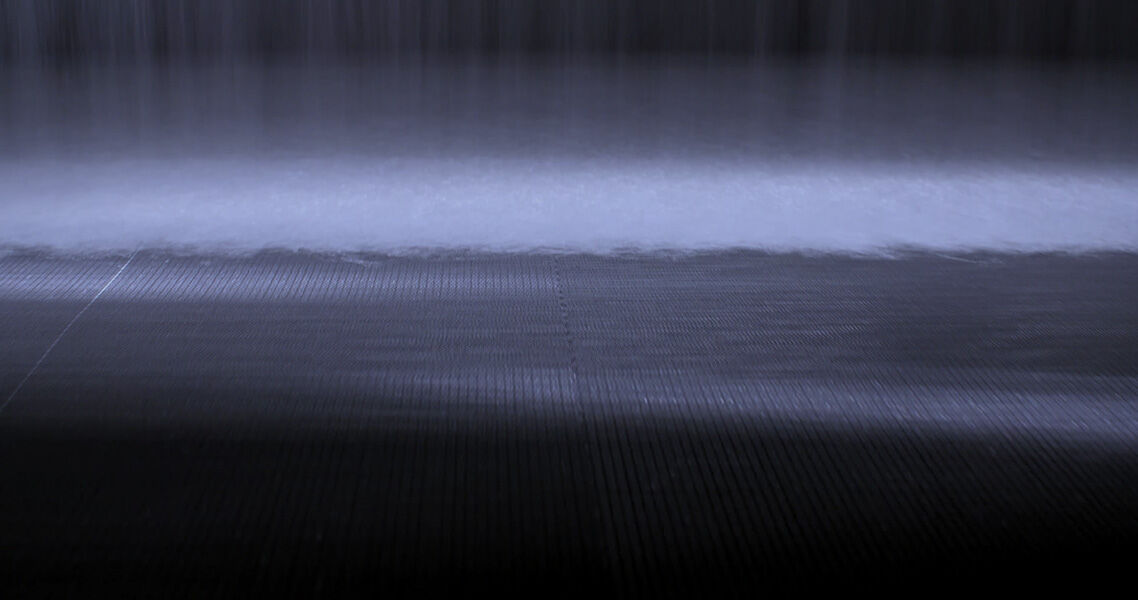

Produce meltblown nonwovens made of the finest filaments for reliable filter applications such as protective face masks.

Playing it safe with constant quality

A fluctuation in meltblown quality can endanger lives. For example, the material used to filter bacteria and viruses in protective face masks must function with absolute reliability. The technology we developed for Reicofil meltblown lines helps you reliably comply with all standards for complex filter nonwovens, so you need never worry about quality again.

What is your product?

Select the right meltblown technology

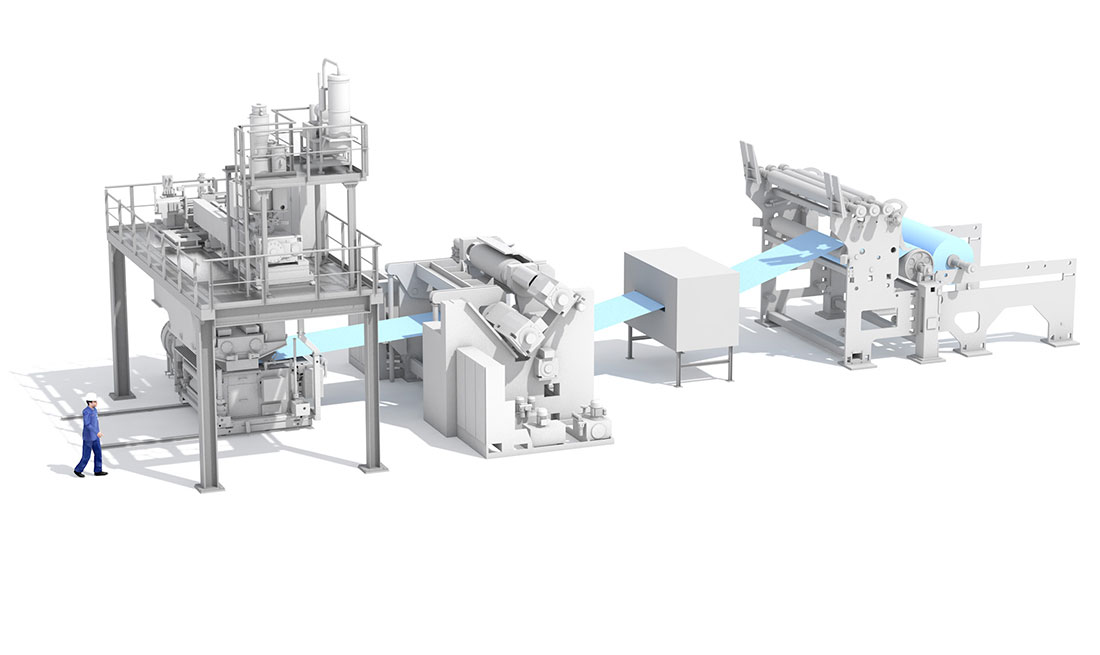

Singlerow Meltblown Technology

Optimum barrier and filtration properties

The polymer is spun through a spinneret provided with several thousand holes in a single row. Streams of hot air exiting at both sides of the spinneret tip attenuate the polymer melt to form ultra-fine filaments that are then blown by high-velocity air onto a collector screen. This results in a meltblown fabric with excellent barrier and filtration properties.

Perfect if you:

Multirow Meltblown Technology

Perfect elasticity and absorption properties

The polymer melt is spun through a spinneret provided with up to 14 rows of fine nozzles. The filaments are blown horizontally onto a drum or vertically onto the collector screen. This results in a meltblown fabric with extremely high elasticity and good absorption properties.

Perfect if you:

Benefit from high-tech

Highlights of RF meltblown lines

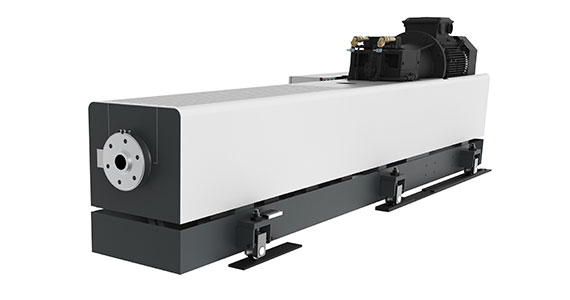

RF meltblown line compact

The most important data at a glance

| Configuration | M, MM |

| Line width | 1000, 1600, 2400, 3200, others on request |

| Max. speed on conveyor belt | product-dependent |

| Max. speed on winder | product-dependent |

| Max. specific throughput | 100 kg/h/m for singlerow 150 kg/h/m for multirow |

| Basis weight | product-dependent |

| Titer-Range Singlerow | < 1 - 5 μm |

| Titer-Range Multirow | 3 - 15 µm |

| Raw materials | |

| PP, PE | included |

| PET/PLA/others | optional |

| Technologies | |

| Bico | optional |

| Charching unit | optional |

Greenfield approach

Optional features

How to use the full potential of your RF Meltblown line

More features or extra convenience? Choose from optional technologies and packages to customize the line for specific needs.

Anti-contamination

The purest nonwoven you have ever produced

- Housing of the spunbond and meltblown system

- Cover above the wire belt

- Protection for downstream equipment

Efficiency

More time for really important things

- Automatic press roll cleaner

- Automatic belt cleaner

- Automatic die inspection system

Energy

Less waste of resources and money

- Energy packages for calenders, winders, dryers

- Energy efficient motors

- Heating with gas

- Heat recovery

- Energy monitor

Digitization

For smarter production

Your plant is constantly producing valuable data. Don't let this potential lie dormant any longer. Our digital features help you produce more conveniently, more profitably and more intelligently.

- Machine control

- DRS Dashboard

- DRS System base module

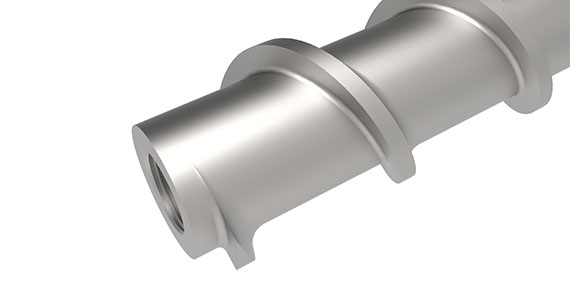

Interchangeable cassette

Combine two technologies

Our interchangeable cassette allows you to switch between singlerow and multirow technology, which is comparable with a standard spinneret change.

Profitability assurance

Reicofil Service

We help you keep your production up and running over the long-term and trouble-free. We support you in expanding your business with existing equipment. We stand by you with support, advice, know-how, and services – in person, by phone, and remote. Do you know about the services we offer?