1.

Arrange a consultation

Flat Dies

Produce quality you can boast about.

The quality of your films, sheets, or tapes is only as good as the quality of the dies. Customized dies are the essential foundation to produce top-class end products.

Off-the-peg dies only deliver quality off-the-peg quality

If you are not achieving the quality you need on your production line, it may be because your die is not optimized to the raw materials and production parameters on your production line. At Reifenhäuser, we develop and manufacture dies that are perfectly adapted to your requirements, so that you can shine with top quality.

Clever features

Highlights of your flat die

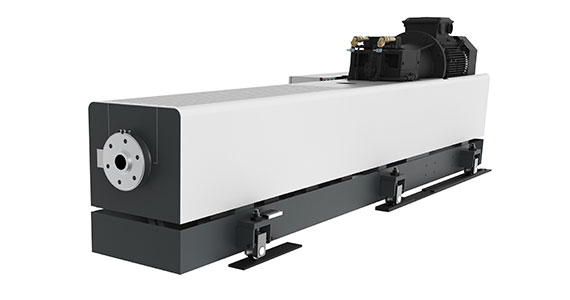

PAM Automation

Perfect quality at the touch of a button, less material and energy consumption and more work safety: with our exclusive PAM automation option, you can control dies and coextrusion adapters fully automatically using electronic actuators.

Flat dies from Reifenhäuser

Our promise

What would you like to produce?

Choose your flat die

For thicker films up to 6 mm

- High product quality

through the combined use of restrictor bars and manual or automatic lip adjustment - added as an option to any die design. - Quick product change

through centrally adjustable die openings and other width adjustment options - High flexibility

through removable lower lips, or height-adjustable lower lips, and the option of different lip inserts - Optional retrofits,

such as die lip heating and cooling, die lip heaters, heatable side plates, and insulation.

PP, PET, PA, PLA, PS, EVOH, HV, TPO, TPE and more

| Type | 2-5 part die body with flex lip in upper die body with adjustable range of 2.5 mm |

| Width range | 75 – 3,500 mm |

| Die gap range | 0.15 – 6 mm |

| Surface Coatings | Chrome, multilayer chrome, CrN mod, metal amorphous, special polymer coatings, tungsten carbide |

For mono and multilayer films ranging from 15 to 350 μm

- Extremely fine profile control

- Optimized positioning of flat die to casting roll also possible with external width adjustment

- Edge encapsulation

- Raw material savings

PP homo, PP copolymer, PET, LDPE, LLDPE, HDPE, PA6, EVOH, EVA, TPU, PLA

Type |

|

Width range | 75 – 7.000 mm |

Die gap range | 0.05 – 12 mm |

Surface Coatings | Chrome, multilayer chrome, CrN mod, metal amorphous, special polymer coating, tungsten carbide |

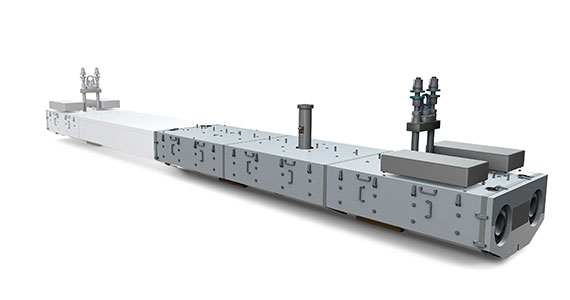

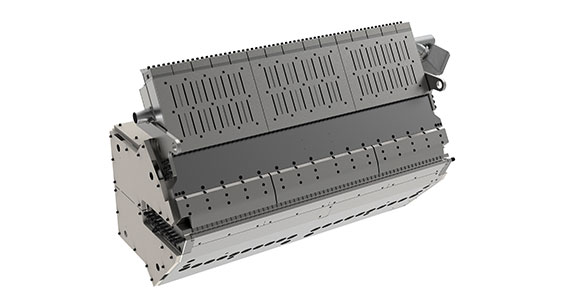

For compact and foamed sheets

Removable and/or sliding lower lip and replaceable upper lip for wide die gap opening range for versions with 45°, 65°, or 90° restrictor bar.

PP, PET, PA, PLA, PS, ABS, PMMA, PC, PVC, and more

| Type | 5-part die body with removable upper and lower lip, fixed upper and adjustable lower lip, restrictor bar and die lip tempering |

| Width range | 500 – 4,000 mm |

| Die gap range | 6 – 60 mm |

| Surface Coatings | Chrome, multilayer chrome, CrN mod, metal amorphous, special polymer coatings |

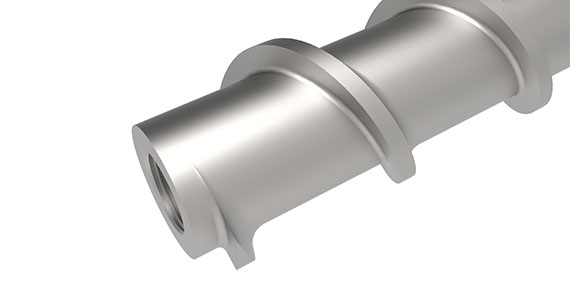

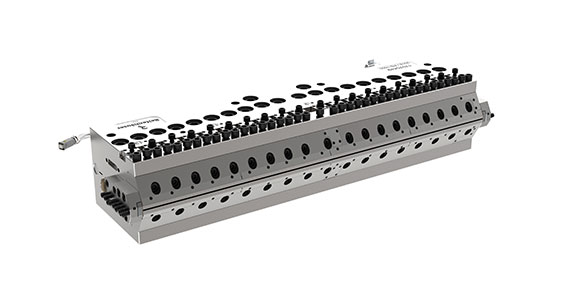

For film tapes

Versatile design due to replaceable and rotating lip which is smooth on one side and optionally grooved on the other side, depending on customer specifications.

PP, HDPE, LDPE, PLA

Type | Two-part die body |

Width range | 750 – 2,500 mm |

Die gap range | 0.05 – 2.0 mm |

Surface coatings | Chrome, multilayer hard chrome, CrN mod, metal amorphous,or special polymer coatings |

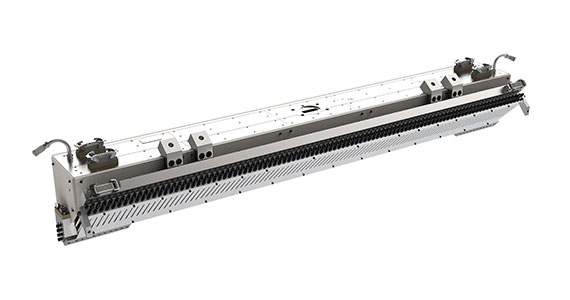

Single or multi-channel dies for biaxially oriented films

- Greater convenience

due to automatic flexible lip adjustment - Long service life

due to die outlet zone custom-designed for material and shape. - Outstanding end product quality

due to plane-parallel and flat surfaces at the die lip outlet zone - Optimized for BOPP, BOPET, or BOPA

PP, PET, PA

| Type | 1 – 5 channel flat die |

| Width range | 500 – 3,000 mm |

| Die gap range | 0.05 – 3.0 mm |

| Surface coatings | Chrome, multilayer hard chrome, CrN mod, metal amorphous, special polymer coatings, hardened die lips, tungsten carbide coated die lips |

| | |

For extrusion coating

- Extremely fine profile control

with automatic flex lip adjustment. - Fast cleaning

due to die splitter - Precise, fast adjustment of product widths

using a combination of external and internal width adjustment. - Reduced edge trim

due to separately adjustable deckling blades with internal width adjustment.

LDPE, LLDPE, EVA, EMA, TPU and more

Type | Two-part die body with flex lip in upper die body with adjustment range of 1.2 mm |

Width range | 750 – 3,500 mm |

Die gap range | 0.05 – 1.2 mm |

Surface Coatings | Chrome, multilayer chrome, CrN mod,metal amorphous, special polymer coatings, hardened die lips |

Producing top quality

How to benefit from Reifenhäuser flat dies

Optimize

quality

Make a name for yourself as a top-quality supplier.

Increase

productivity

Achieve profitable production.

Maximize

service life

Save unnecessary maintenance costs.

Gain

convenience

Benefit from no-stress production, even with frequent product changes.

Achieve profitability

Service

We help you achieve long-term production success and support you in expanding your business with existing equipment. We are at your side with support, advice, know-how and services - in person, by phone and remotely. Do you already know the following services available from us?